Our great-grandfathers built bathhouses from logs. Modern logs are processed on a machine and acquire an attractive appearance. Baths continue to be built from simple logs, time-tested and rounded. Both options are suitable and have their advantages. But what diameter of log is needed for a bathhouse? How not to make mistakes and choose the right material? Will the walls freeze in winter if a small section is used? We'll talk about all this in more detail below.

The log for the bathhouse is selected with the correct diameter so that the walls do not freeze and retain heat well.

Advantages and disadvantages

Any wooden house is good for its light weight and environmental friendliness. A log building has its own characteristics. In what ways is a log inferior to timber?

- The log is less technologically advanced, the stand made from it is more difficult and slower;

- When such a bathhouse (log house) is built, the layout is adjusted to the length of the log;

- At the junction of the crowns, the thickness of the wall is equal to the width of the groove and, accordingly, approximately half the diameter of the log. This negatively affects heat retention in the room.;

Advantages of a log house for a bath:

- The closed joints of the crowns and the external appearance of the log house make it possible to refuse cladding;

- A log, unlike timber, does not have through cracks through the middle.

Stage 4. Waterproofing the base

Waterproofing a strip foundation

Treat the surface of the foundation with molten bitumen and lay a layer of roofing material on top. After the bitumen has completely dried, repeat the procedure. As a result, you will have reliable two-layer waterproofing.

Waterproofing with mastic

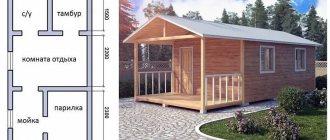

Building area

Ideally, each bathhouse visitor should have from 1.3 to one and a half square meters of space in the dressing room or 1 m2 in the steam room. The optimal washing area for one person is 2.25-2.4 sq.m. More than 80 cm of free space should be left between the shower stall (or a bench in a soap room, the dimensions of the bench are 0.5 x 0.9 meters) for ease of movement. In fact, this area can be slightly increased for greater comfort.

The optimal usable area of a bathhouse for 2-3 people with three rooms (shower room, dressing room and the steam room itself with an area ratio of 1.5: 2: 1) is approximately 10 square meters.

How do you know if the planned area will be enough for you? The easiest way is to outline all the walls and partitions in steps. In winter, it is better to do this in the snow, and in summer, mark with sand or pull ropes.

“Tread down” the dimensions of the future bathhouse on the snow

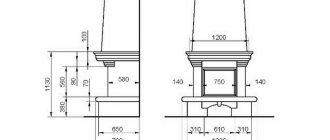

Bake

Stone stoves are used to heat the bathhouse and heat the water. In such furnaces, fairly large natural stones (boulders, pebbles, granite) serve as heat accumulators, which are heated by hot gases coming out of the firebox. Stones are taken at the rate of 60 kg per 1 m³ of steam room, sometimes adding up to 20% pig iron. The stove is positioned so that the steam room, washing room and dressing room are heated simultaneously (but, of course, in different modes).

The stove-heater is made of refractory or ordinary red brick in clay mortar with the addition of fireclay sand or crushed refractory brick. To make a firebox, approximately 150-200 bricks, 20-27 kg of clay, 20-27 kg of fireclay sand are consumed.

The height of the firebox, counting from the bottom of the boiler, must be at least 50 cm so that the required amount of fuel can be placed.

When making a stove, it is necessary to ensure that there is a space of 4-5 cm between the walls of the stove and the boiler, then hot gases wash the boiler from all sides and heat the water faster. The draft in furnaces depends on the height of the pipe and other data. The pipe near the attic floor must have a groove or fluff 38 cm thick, counting from smoke. The roof sheathing and rafters should not reach 15 cm from the pipe (this gap can be closed with roofing steel, slate, or tiles).

2007, Dobrosrub

Shrinkage

When freshly cut, wood contains a significant amount of moisture. Free moisture is found in wood cavities. Leaving the material, it does not affect its shape and linear dimensions. Bound moisture is another matter - that which is present in the thickness of the cell membranes. Its content in wood reaches up to 30% and removal entails warping, cracking and shrinkage (reduction in linear dimensions) of the timber.

During construction, you will have to add 5–7 cm for each meter of height to the expected height of the bathhouse from the log house. The allowance for sedimentary deformation is also included in the height of door and window openings. The gap above the box is temporarily filled with insulation, and after two years it is caulked or covered with an additional element (if the shrinkage turned out to be less than expected).

Installation of internal partitions (non-shrinkable) and cladding are timely only one to two years after the construction of the log bathhouse for shrinkage from logs. The period of “rest” depends on the size of the log house and the weather.

For a small bathhouse, 10–11 months of settling may be enough - if construction began after the autumn rains and the summer was dry.

Attention! The gap between the partition and the ceiling is required even after drying, at least 1-2 centimeters. Horizontal shrinkage - along the wood fibers - is only a few tenths of a percent, so when building a log bathhouse, no attention is paid to shrinkage along the length

Horizontal shrinkage - along the wood fibers - is only a few tenths of a percent, so when building a log bathhouse, no attention is paid to lengthwise shrinkage.

A bathhouse can be built from brick, but many people see a log house as a “historically correct” solution.

If you say the word “bathhouse”, then most likely an image of a log house will appear.

In order for log houses and bathhouses to serve for a long time, the work of professional carpenters, assemblers, roofers, healthy timber and their competent processing are needed. Proper use will prevent early cracking and twisting of the wood.

Stage 2. Timber processing

Processing a log for scraping

Step 1. After the consumables have been delivered to you (or you have cut and delivered them yourself), they need 25-30 days to rest.

Step 2. Next, carefully examine and sort through the logs - keep only the highest quality ones, and discard defective or damaged ones.

Step 3. Then start processing. First, peel the bark from the logs (do this carefully so that they do not crack), leaving a little of it on the sides - about a 15-centimeter strip on each side.

Step 4. After processing, place the logs in storage approximately 25 cm from the surface of the ground. You can stack it however you like - in stacks, packs, etc., the main thing is that the distance between the logs is 7-10 cm.

Scheme for preparing logs for building a log house

Shrinkage

When freshly cut, wood contains a significant amount of moisture. Free moisture is found in wood cavities. Leaving the material, it does not affect its shape and linear dimensions. Bound moisture is another matter - that which is present in the thickness of the cell membranes. Its content in wood reaches up to 30% and removal entails warping, cracking and shrinkage (reduction in linear dimensions) of the timber.

During construction, you will have to add 5–7 cm for each meter of height to the expected height of the bathhouse from the log house. The allowance for sedimentary deformation is also included in the height of door and window openings. The gap above the box is temporarily filled with insulation, and after two years it is caulked or covered with an additional element (if the shrinkage turned out to be less than expected).

Installation of internal partitions (non-shrinkable) and cladding are timely only one to two years after the construction of the log bathhouse for shrinkage from logs. The period of “rest” depends on the size of the log house and the weather.

For a small bathhouse, 10–11 months of settling may be enough - if construction began after the autumn rains and the summer was dry.

Attention! The gap between the partition and the ceiling is required even after drying, at least 1-2 centimeters.

Horizontal shrinkage - along the wood fibers - is only a few tenths of a percent, so when building a log bathhouse, no attention is paid to lengthwise shrinkage.

A bathhouse can be built from brick, but many people see a log house as a “historically correct” solution.

If you say the word “bathhouse”, then most likely an image of a log house will appear.

In order for log houses and bathhouses to serve for a long time, the work of professional carpenters, assemblers, roofers, healthy timber and their competent processing are needed. Proper use will prevent early cracking and twisting of the wood.

Stage 8. Caulking logs

Types of tools and caulking methods

After shrinkage is completed, the log house is caulked. To do this, prepare the following equipment:

- hammer;

- caulk (made of wood or metal).

Proceed to work only after the insulation has completely dried. First, twist the material (tow or moss) into a rope, then hammer it between the crowns with a hammer and caulk.

Caulk

You can use tape jute - in this case, the material is simply fixed with nails or a mounting stapler.

Primary and secondary caulking of a log house

Bathhouse made of large logs

One of the possible options for constructing a bathhouse box is to use debarked and ground blanks of large diameter. If you build walls from Siberian pine or cedar, and their diameter often reaches 50-60 cm, the result will be a very warm and, most importantly, durable room. On average, hand-cut bathhouses made from large logs last for 40-50 years, no less.

The large size of the workpiece gives the bath an unusual look

For steam rooms and saunas in Arctic cold conditions, log houses are built from large-diameter logs, most often the famous Canadian red cedar. The diameter of the chopped log can reach 110-140 cm, resulting in a very warm room, but such baths are recommended to be built for dry and very cold climates, otherwise the outer surface of the walls will quickly become covered with cracks due to fluctuations in air humidity.

Log houses made from large logs require the use of construction equipment

Log houses are assembled by cutting the corners “into the bowl”, this is due to the high cost of the logs and the desire of the builders to save material as much as possible; sometimes the root parts are not even cut off.

Doors

Doors are made on dowels from thick tongue-and-groove boards or from boards with selected quarters. The door dimensions should be 5 mm less than the distance between the side folds (quarters). If the doors fit tightly into the quarters of the frame, then, swelling from water and steam, they may jam. In the steam room and washing room, their width should not exceed 70-75 cm. The height of the doors, as a rule, is 160-170 cm. It is recommended to make the threshold high - 25-30 cm from the floor. This is somewhat inconvenient, but it retains heat better, especially at floor level.

What determines the size of the bath

The first thing that determines the size of the bathhouse is whether it is free-standing or serves as an extension to the house. In the second case, one of the walls of the house will turn into a partition between the bathhouse and the main building.

One of the extension options

Bathhouse attached to a house made of rounded logs

Also, the size of the bath depends on the size of the site and the amount of free space. It is irrational to build a 12x12 meter bathhouse on six acres. And, on the contrary, on a plot of a couple of hectares you can safely locate a bathhouse complex of any size.

It is worth choosing the size of the bathhouse according to the number of visitors. If you plan to go to the steam room in splendid isolation, then a modest building of 2x3 or 3x4 meters will be more than enough. For a large family, it is better to choose a larger size, from 6x6 m to 6x12 or more, of course, if you do not plan to take turns occupying the steam room.

Bathhouse project 2x3 m

Bathhouse 2x3 m, project

It is better to choose the dimensions of the steam room based on your preferences - whether you like to steam while sitting or lying down, sitting on a shelf with your knees bent, or lying stretched out to your full height. But do not rush to build a steam room of immense area, so as not to spend too much time and resources on heating.

Schemes for placing visitors in the steam room

Table. Minimum dimensions of a bathhouse and rooms in it for 1-2 people when seated

| Premises | One man | Two people |

| Steam room area, m2 | 0,98 | 0,98 |

| Recommended steam room dimensions, cm | 850x1150 | 850x1150 |

| Waiting room area, m2 | Waiting room area, m2 | 2,15 |

| Recommended dressing room dimensions, cm | 1000x2150 | 1000x2600 |

| Washing area, m2 | 1,49 | 1,67 |

| Recommended washing area dimensions, cm | 1150x1300 | 1150x1450 |

| Total bath area, m2 | 4,62 | 5,59 |

| Minimum dimensions, cm | 2150x2150 | 2150x2600 |

Table. Minimum dimensions of a bathhouse and rooms in it for 2-4 people when placed lying down

| Premises | 2-3 people | 2-3 people | 3 people | 4 people |

| Steam room area, m2 | 2,34 | 2,34 | 2,7 | 3,0 |

| Recommended steam room dimensions, cm | 1300x1800 | 1300x1800 | 1400x1800 | 1500x2000 |

| Waiting room area, m2 | 4,03 | 4,03 | 5,4 | 5,4 |

| Recommended dressing room dimensions, cm | 1300x3100 | 1400x3400 | 1500x3600 | 1800x3600 |

| Washing area, m2 | 3,24 | 3,6 | 3,78 | 4,2 |

| Recommended washing area dimensions, cm | 1800x1800 | 1800x1800 | 1800x2100 | 2000x2100 |

| Total bath area, m2 | 9,61 | 10,88 | 10,88 | 11,88 |

| Minimum dimensions, cm | 3100x3100 | 3200x3400 | 3300x3600 | 3600x3800 |

You can refer to GOST 52493-2005, which regulates the operation of baths and showers. But this set of rules was developed for public baths, and therefore for an individual builder it is only advisory. Paragraph 5 of GOST states that the dimensions of the bathhouse itself and the premises in it may vary depending on the climatic conditions of the area and national traditions.

Where to place it?

The ideal place to build a bathhouse is a gently sloping bank of a river, lake, or pond, protected from the wind by trees. If the bathhouse is part of a system of outbuildings, the distance between it and other buildings for fire safety reasons should be at least 20 m. In residential buildings and summer cottages located outside densely populated areas, the bathhouse can be built under the same roof as the main building. It is also necessary to provide for the possibility of draining contaminated water, so it is better to locate the bathhouse in an elevated place - the possibility of minimal deepening of the sewer tray.

In ancient times, a settler who came to live in a new place began the development of the site by building a bathhouse, in which the family lived the entire time necessary to build the house. A city dweller who is developing a garden plot can now do the same: build a temporary building - a bathhouse and live in it until the construction of the house is completed.

Methods for assembling logs into a log house

An example of cutting into a thicket with your own hands during the assembly of a log bathhouse

The logs need to be connected using one method, either in a paw or in a lock. You should not take logs that are shorter than the wall of the bathhouse. Each joint is an additional loss of heat, and this is unacceptable in a bathhouse.

The logs are assembled using metal brackets, wooden dowels or using rectangular wedges. Rectangular wedges are the most labor-intensive method, but one of the best in terms of strength. To do this, wooden blocks measuring 10–15 cm in length, 5–7 cm in width, and 3–5 cm in thickness are made. Grooves are cut into the log on both sides to suit the size. The block is driven into the lower log with a hammer, and the upper one is put on it.

We have already talked about how to connect logs using dowels (). Iron elements for joining wooden parts are not recommended. When drying, the logs may crack and the glands will be visible, and this is unsightly.

When assembling a log house, window and door openings are cut out in half. It is worth leaving a couple of connecting links; they will hold the geometry of the log house for the bathhouse during shrinkage.

Treatment inside the bath

The log house needs protection from all sides , but from the outside it is simpler, more precisely, there simply are not the restrictions that apply inside, since we are talking about a bathhouse. The fact is that the compounds that should be used for processing are often poisonous, especially for antiseptic impregnations. And the sauna is hot and humid, so the substances with which the logs are soaked will enter the air you breathe, which surrounds your skin.

Therefore, now we will only talk about the acceptable processing of logs inside the bathhouse. However, it will differ depending on the premises. So for the dressing room or hallway there are no restrictions on the use of toxic antiseptics. The rest room can also be treated with them.

ADVICE! When choosing an antiseptic for interior work, check with the seller or Google that we are talking about a bathhouse.

In

the washing room , you should use compounds that are not afraid of water, and most antiseptics are water-soluble.

In the steam room , you can use chlorine-based bleach - it will both lighten the surface of the wood and serve as an antiseptic. You can use the steam room only after the smell of bleach disappears.

In the future, you can do simple moisture protection, because mold settles on damp wood. For moisture protection, use oil and/or wax-based compositions, or Finnish acrylic sauna varnishes, to which they add antiseptics acceptable for steam rooms.

The seams can be filled with wood sealant , and the surface of the logs can simply be sanded to reveal a beautiful “moiré” texture. Painting is acceptable almost everywhere, but in the steam room you should use only those paints that are intended for it. Paints suitable for bathrooms will work in the washroom. We have a detailed section about bath paints.

How to caulk

The idea of caulking a bathhouse made of logs suggests that not all bathhouse owners are familiar with modern means of sealing joints (or do not consider them the best). Traditional methods, of course, are time-tested, but they are very labor-intensive and require periodic labor-intensive updating, since the log house is constantly gradually changing its dimensions during the first 20 years of life.

As for materials, are usually used for caulking . However, below we will provide a link to a video of a master who categorically does not recommend caulking with jute, because it absorbs moisture well. He considers flax wool to be the optimal material. Moss is traditional, but not widespread everywhere.

Tow comes in different qualities. The worse one has inclusions of all kinds of straw. Masters also do not recommend using it, because some of it will crumble over time. Good quality flax tow is an excellent material for caulking.

Linen batting is a quilted fabric that is somewhat reminiscent of jute, but differs from it in quality. It is convenient for work and is not inferior to tow in terms of heat-insulating properties.

See also: Are we installing a log house or timber? Interventional insulation for a bathhouse: which one to choose, which is better, natural or modern?

There are two different methods for placing caulking material in the cracks between logs. The first is called “pigtail” or “stretch”, the second “set”. Watch videos that show how the masters work.

Caulk with moss:

Pakley:

Lnovatin:

Height of rooms in the bathhouse

A prerequisite is that there must be a threshold before entering the steam room, or the level of the entire floor of the steam room should be 10-15 cm higher than the floor level in the washing room or rest room. In the washing room, it is recommended to make the floors 3 cm lower than the level of the finished coating in the rest room.

Threshold

There is a tradition according to which the ceiling height is chosen. Measure the height of the tallest member of the family and make a reserve so that it is convenient to wave the bath broom. The result is from two to two and a half meters. The optimal ceiling height is 210 centimeters.

Steaming should be comfortable

If you make the ceiling too high, it will be very comfortable to sit on the top shelf and steam, but the volume of the steam room will increase, and this will lead to unnecessary fuel consumption for heating the room.

Options for accommodating people in the steam room

If you want to sit on the top shelf, then take a distance from it to the ceiling of 100 cm. For a “lying” position, fifty centimeters is enough, but it may be too hot, because the temperature distribution in the steam room is not uniform:

- the floor is at its lowest temperature;

- every 30 centimeters the temperature rises by about 10°C.

Thermometer in the steam room

The main thing is that the top shelf is higher than the stones in the stove (the heater is usually located one meter from the floor), then the atmosphere will be the best.

There are standards for the location of windows in a bathhouse:

- the bottom of the window opening should not be less than 120 cm from the finished floor line;

- in showers and soap rooms this value is one and a half meters.

Windows in the bathhouse

Which height do you prefer?

Centuries of experience have shown that the universal ceiling height in a bathhouse is 2.2 m. This means that when choosing a log house you should not listen to the manufacturer’s reasoning that small dimensions will help save heat. Please note that:

- floor joists cut between the second and third crown (0.35 cm of total height is lost);

- the attic floor is installed in the penultimate crown (minus 0.16 m);

- the thickness of the floorboard is from 3 to 5 cm, and the lining on the ceiling is about 2 cm;

- The shrinkage of the building is usually 1 cm from each crown (minus another 0.15 m).

Attention! Taking these design features into account, it turns out that the bathhouse frame needs to be selected with a height of 2.9-3.0 m.

What should be the thickness of the walls?

The thickness of the log for the log house depends on how the building is intended to be used: for permanent or temporary residence. In addition, this parameter depends on the climatic conditions of the region: in severe frosts, a log that is too thin will freeze, and a large amount of fuel will have to be spent for heating. The thickness of the log walls for central Russia is determined as follows:

Logs less than 18 cm thick can only be used for non-residential structures. These are gazebos, workshops, outbuildings.

- A country house can be built from logs 20-22 cm thick. Such a building will be designed for summer living, in addition, it will be comfortable in spring and autumn with proper insulation.

- The thickness of a log house for permanent residence is 22-30 cm. This is a fairly expensive solution, but purchasing logs at a high price will allow you to save on purchasing fuel for heating in the future.

- A log 30-40 cm thick is the most reliable, warm and durable option, which, however, will be very expensive. However, you need to take into account that less logs will be required for the construction of walls due to the increased thickness, so the difference in price will be less significant.

If finances allow, you can build a building from thicker material. Economically, this is not the most profitable solution, but the house will be truly strong and as durable as possible.

In addition, a building made of thick logs looks very beautiful: it is a powerful structure that will become a real fortress and can last for many years. The large thickness of the log house also allows you to save on insulation work, since the material itself retains heat well.

If you want to build a log house, the thickness of the walls is not the only parameter that directly affects the energy efficiency of the building

Most of the heat escapes through the openings of doors and windows, so it is important to take care of the correct installation of window and door units. If a large glazing area is expected, you will have to purchase two- and three-chamber double-glazed windows, and all seams in any case will need to be carefully closed and insulated

What should a log bathhouse look like?

A special question is: what should be the thickness of a log house for a bathhouse? This room should be warm, since both the comfort and benefits of bath procedures will depend on this. At the same time, the bathhouse is not used constantly, and some do not use it at all in winter, so it is not advisable to spend too much on purchasing lumber.

For the conditions of central Russia, the optimal thickness of the walls of a log bathhouse is 20-25 cm. This will be enough to maintain a comfortable atmosphere inside the bathhouse, while the material is sold at an affordable price. In any case, when building a bathhouse, you will have to spend money on the purchase of insulation: it is necessary to lay inter-crown rolled material when constructing the walls, in addition, the ceiling and floor require mandatory insulation.

Savings when buying logs for a log house leads to the fact that in the future you will have to constantly spend money on energy resources: the bathhouse will have to be heated for a very long time, and it will begin to cool down very quickly. All this will lead to an insufficient level of comfort, and the building will require additional insulation.

Factors determining the choice of log diameter when building a bathhouse

In today's conditions, a rounded log is used to build a bathhouse, the diameter of which varies within an extremely wide range - from 14-16 cm to 36-40 cm. A logical consequence of this fact is the difficulty that most owners experience in determining the value of the parameter in question that is suitable for their specific conditions. Taking into account several of the most significant criteria helps to simplify the selection procedure, including:

Taking into account the three listed factors helps to correctly determine the diameter of the rounded log required for use in construction. As a result, material consumption and, as a consequence, the cost of construction will be as low as possible while simultaneously ensuring the required level of comfort and convenience.

Features of constructing a bathhouse from rounded logs

The construction of bathhouses from rounded logs is much faster and easier, since the products are manufactured in a factory, where they are given a certain shape and size. All of them are numbered and have grooves for easier installation.

However, you should know that products are produced for certain bathhouse projects made of rounded logs, which are presented in the catalogs of woodworking enterprises. From the options presented, you can select the most suitable one and place an order for the manufacture of products. After receiving the kit, there will be no problems assembling the bathhouse. Detailed instructions are also included with the log house.

When building a bathhouse from rounded logs, certain requirements must be observed:

- for better contact with the foundation, the casing crown should be trimmed from the bottom side;

- since the logs lost their protective layer during processing, all products must be impregnated with a fire-retardant agent;

- For vertical stability of the structure, it is necessary to connect the logs with dowels made of hard wood of oak, beech or birch, which are recessed into the product by at least 3 cm;

- holes for dowels should alternate in a checkerboard pattern along the entire length and height of the wall in increments of 0.8-1.2 m and a length of 2-3 crowns;

The rounded log has undergone mechanical processing in production and therefore has the same diameter along its length, as well as ready-made grooves, which greatly facilitates the construction of a bathhouse

- before drilling holes for the dowels, the logs should be secured using temporary nails, which are removed after connection;

- Between the products, heat-insulating material in the form of tow or flax fiber must be placed, which is secured with staples;

- the construction of each subsequent crown must be controlled using a level to avoid distortion of the frame;

- to prevent the destruction of door and window frames during shrinkage of the log house, the openings are framed with casing beams with a gap of 3% of the height of the opening, which is filled with insulation.

Stage 9. Roof

As soon as the tree shrinks, you can begin building the roof. If you do this earlier, the roof will simply collapse.

Step 1. Place wooden beams on the wall framing (we have already talked about this).

Step 2. Fix the beams and attach the rafter legs to them in 1 m increments. In the ridge part, cut the rafters at the appropriate angle for the connection.

Step 3. Nail a solid board deck to the rafters (if you plan to use rolled roofing material) or make a sheathing (if you use slate, tiles, etc.).

Step 4. Install the roofing according to the instructions for the specific material.

Step 5. Cover the ridge with galvanized sheet steel to protect it from aggressive environmental influences.

Step 6. Cover the roof gables with siding or clapboard.

After this, proceed to further planned work - pouring a concrete screed or building a wooden floor (in the second case, the logs are cut into the logs of the second crown and fixed), install insulation, carry out interior finishing and arrangement of the steam room according to your project.

Preparing a working draft

It is recommended to build a bathhouse 15 meters from a wooden house

Design is carried out taking into account the following parameters.

Placement - the log house is located at least 15 m from the residential building or at least 10 m if the house is concrete or stone. Choose an elevated location, as this makes it easier to remove moisture. It is better if the building is protected from the winds by bushes and trees or a fence. In a small bathhouse they plan only a steam room and a vestibule. The washing room can be combined by arranging a bucket or ladle for dousing, or place it under a canopy

If the space allows, they plan a steam room, a washing room, a locker room, and possibly a guest room. It is important to design effective ventilation. Otherwise, the building will become damp. When planning, take into account the size of the log

It is necessary to calculate where they will be joined, what is the permissible length of the wall, etc.

The use of rounded and planed logs significantly simplifies the design.

The thickness of the log for a bath: selection criteria and specific numbers

Choosing the thickness of a log for a bathhouse is an important stage of design and construction, affecting many aspects. Firstly, it depends on whether you can use the steam room in winter or only in summer. Secondly, the diameter of the log directly affects the cost of construction. Thirdly, the aesthetics of the building depends on the choice of material. Let's look at all these nuances in more detail.

Log houses made of debarked logs

Durable, eco-friendly log houses made from debarked logs are ideal natural housing, the quality of which will satisfy many generations of your family.

Technological features

When constructing log houses from debarked logs, adherence to technology is doubly important. Wild timber involves manual preparation of timber. The approach requires extreme care when installing the structure and precision when cutting the corners of the building.

The advantages inherent in the building material completely compensate for the labor-intensive construction process required to build a log house from debarked logs. The price of the service corresponds to the quality of the entire building. Its exceptional performance characteristics guarantee a long, comfortable stay in an environmentally friendly, warm room.

The debarked tree undergoes minimal external processing. During the process of using an ax or other tools, only the top thin layer of bark is removed. The remaining sapwood ensures the safety of the inner layers of the tree, guaranteeing the special strength of each crown and the entire structure.

The use of hand-finished material requires special skill from the carpenters performing the assembly. Numerous irregularities and natural protrusions are preserved during the debarking process, making it difficult to tightly fit the logs and correct cutting of corners. The qualifications of workers with this option for constructing a country house is a key factor.

“Novy Srub” is a company that successfully implements its own unique design solutions. Using debarked logs, our carpenters, who have significant practical experience, tightly join the elements, laying natural insulation between the crowns. By carrying out high-precision cutting of corners “into the claw” or “into the bowl”, specialists organize reliable protection of “weak” places, preventing the occurrence of heat loss.

The experience of our builders allows us to guarantee exceptional quality to each client.

Advantages of debarked log houses

Thanks to the use of hand-hewn logs, it is possible to:

- significantly increase the service life of the structure;

- build a unique building, the external design of which will be unique thanks to a special cutting technology;

- to build environmentally friendly “living” housing with clean air inside, impregnated with resin vapors, which has a beneficial effect on health.

Using a log house made of debarked logs, the price of which is our competitive advantage, we will construct a building of any structural complexity.

Seasonality of bathhouse operation and maximum frosts

Let's go from simple to complex. First, let's look at the case when a bathhouse is being built, for example, at a dacha, which you visit only in the warm season, since there is no home there for permanent residence (or for other reasons). For summer use, the choice of log diameter is not very important, and in most cases it is based only on available funds and common sense. A 150-mm frame, and an even less thick one, will be sufficient. This will not reduce the pleasure of taking bath procedures in any way. But the budget is different.

In general, a log with a diameter of 200 mm is considered in central Russia to be the golden mean for the construction of baths. It should be remembered that this, after all, is not a residential building, and the requirements for thermal insulation properties here are not so high. Therefore, looking towards logs 36-50 cm thick is not particularly worthwhile. Although there are exceptions to this rule.

Assembly of the finished log house

The construction of houses and baths from rounded logs can be carried out on the basis of a finished log house. This is faster and more reliable, since a house kit with already numbered logs will be delivered to your site, which makes assembly simple and quick.

Each log house is supplemented with instructions, in accordance with which its creation is carried out. But you still need to follow some rules:

- the casing crown must be trimmed from the bottom side - this is necessary for a tight connection of the first row to the foundation, which must be waterproofed with two layers of roofing material;

- impregnation with fire and bioprotective agents is required in all areas of the log house where the logs will be adjacent to each other;

- the connection of materials is carried out using durable dowels made of hardwood - they must be recessed into the log to a depth of at least 3 cm;

- When laying logs, flax tow or fiber is placed between them.

Construction of a foundation for a timber bathhouse

A strong and massive bathhouse made of timber with your own hands can be erected on one of two types of foundation: strip and columnar.

To make a strip formwork, you need to build formwork around the entire perimeter and fill it with concrete - exactly to the depth of soil freezing. The height of the foundation itself should be at least half a meter above the ground: this is the only way to protect the lower crowns of beams from excess dampness. But inside the perimeter of the foundation you will need to pour strips of crushed stone or sand. And after two to three weeks, as soon as the concrete hardens, you can begin to lay the first rows of the log house.

To make a columnar foundation for a log bathhouse, you will have to place brick pillars along the perimeter, corners and future locations of the internal load-bearing walls. Under each of the pillars you need to make a concrete “cushion” to avoid their subsidence. The distance between such supports should be 1.5 m, and in rare cases - 2 m.

But, no matter what foundation is chosen, it must be strengthened with reinforcement - for strength and fastening of the crowns. And, of course, ensure reliable waterproofing between the base and the first crown. To do this, a layer of molten bitumen is applied to the horizontal surface of the foundation, which is covered with a continuous layer of roofing felt. And after it hardens, the whole procedure must be done again.

Conclusion

Now you know how to choose the optimal diameter of a log for permanent residence, so that you feel cozy and comfortable in your home. But I would like to remind you that the building has many places that are sources of heat loss, even if you choose a log house of the required size. These elements include door and window openings, because a lot depends on the quality of the product!

In order for the house to be warm, you need to take into account a lot of specific points at the design stage: floor, walls, ceilings, basement (if any), openings

In the video presented in this article you will find additional information on this topic.

The most common log sizes used in practice

The rich accumulated experience in the practical construction of baths shows that most often when constructing baths, rounded logs of the following diameters are used:

The most typical log diameters, most often used in domestic conditions, are considered to be three sizes - 20, 22 and 24 cm. The latter option is universal, as it is also used in the construction of permanent residential buildings that are intended for permanent residence. It should be noted that reputable manufacturers of log houses always offer the client a choice of at least 3-4 options for the size of rounded logs.

Source

Materials and cutting methods

The log house of the bathhouse can be assembled from logs or timber. In turn, the trunks are divided into rounded or manually debarked. The beams can be ordinary, glued or profiled.

- The building material can be ordinary logs processed with an axe. Many craftsmen now use a more modern tool for debarking - a scraper or plane. After this, the trunks need to be impregnated with an antiseptic composition and fire retardant.

Rounded logs.

- Specialized woodworking machines are used to produce rounded logs. This material has more precise geometric dimensions. It is also impregnated with protective agents.

- Timber is more expensive than logs. However, log houses for 4x6 baths are more durable from it. They are almost not subject to deformation and exhibit very little shrinkage.

- In most cases, lumber for chopped walls is made from inexpensive coniferous trees - pine, spruce, fir.

Cutting options

Cutting into a cup.

At the moment, companies assembling log houses use two main types of cutting corners - “into the cup” and “into the claw”.

In the first case, the rims have protrusions at the corners. With the second method, the logs are assembled end-to-end at the corners, without them going beyond the plane of the walls.

Cutting by hand is less expensive because it consumes less wood. However, it is also more complex, so it requires experienced craftsmen to implement it. The danger of defects with the second method is quite high; this is fraught with freezing and blowing through the corners. When cutting into a bowl, such risks are eliminated.

This method is more practical, provides better thermal insulation and strength of the corners, as well as the aesthetics of the log house as a whole. Cutting "in the paw" does not look so beautiful. Therefore, many bathhouse owners prefer to cover the walls in this case with decorative cladding.

What wood to choose for a log house

We make log cabins from winter forests, using pine, spruce or aspen. Winter wood contains less moisture, so when it dries out it produces fewer cracks. We also specially treat the cylinders so that the cracks are sealed from bad weather.

Spruce is a traditional wood for making log cabins. Suitable for both baths and home.

Pine is a denser wood, more expensive because it's harder to cut it. Suitable for both baths and home.

Aspen is used only for rounding. It is believed that the spirit in such a bath is “lighter”. Not recommended for home use.

Tips for purchasing and harvesting lumber

Logs must be free from insects and mechanical damage. You should choose straight trunks without curvature that have the smallest discrepancy in the diameters of the ends - up to 3 cm. For lumber longer than 3 meters, a permissible deviation of 1 cm per 1 linear meter is accepted.

Important! The complexity of the work, as well as the cost of the log house, is directly proportional to the thickness of the logs - the thicker it is, the more difficult it is to carry out construction and the more expensive it will cost.

Self-harvesting logs:

- Self-cutting of forests is carried out in winter, when the wood has a moisture content of up to 10-12% - this ensures minimal shrinkage of the building and makes it possible to use material with a smaller cross-section.

- When choosing trunks, 1 cm is added to the calculated diameter of the logs for subsequent processing.

- When using an electric or chainsaw, it must be taken into account that after using these tools, the treated surface becomes significantly tousled, as a result of which it is more susceptible to rotting. To prevent this, craftsmen recommend not to reach the marking of 5-10 mm, to cut down the wood between pre-made cross-cuts and to do the finishing hew with an axe.

- For construction, freshly cut logs are used, which are easier to process. After drying in a laid frame, such wood is less deformed and cracks.

- After removing the bark, the lumber is stacked, placing bars between the layers to organize air circulation. The logs are stored under a canopy or covered with moisture-proof material, which also protects from direct sunlight. Drying lasts two weeks, after which the felling of the log house begins. Overdried wood is difficult to process.

- To reduce cracking of logs on the facades, notches are made in each of them on the side opposite to the longitudinal groove. Their depth should be up to ¼ of the diameter of the lumber. These cuts are designed to compensate for internal stresses arising during the processes of wetting and drying under the influence of atmospheric factors, and, as a result, to prevent the occurrence of cracks.

Proper selection and harvesting of timber for construction allows you to obtain a durable, warm and aesthetically attractive bathhouse.

Source

Special cases

It probably remains to clarify a couple of points related to special cases - what material is suitable for a log bathhouse with a second floor, and are there log barrel bathhouses?

For a bathhouse with a second floor

A two-story wooden bathhouse is often built from logs with a diameter of 20 to 28 cm . We came to this conclusion after reviewing the proposals of a variety of construction companies that build such turnkey baths. However, the customer is sometimes given the opportunity to choose the diameter of the logs himself.

From this we can conclude that no special requirements for the thickness of logs are provided in the case of a two-story building, but the foundation must be appropriate for the future load. A civil engineer must calculate the foundation.

For a barrel bath

Let's say right away: a log is not used for a barrel bath . In all the options that we saw, it was an edged board. As an option - edged tongue and groove.

Barrel baths arose as a type of mobile baths, which were also relatively cheap. It is logical that neither in design, nor in purpose, nor in price, solid logs are suitable as wall material here.

But if any of the readers have seen something that proves the opposite, we will be glad to see the proof link