Many people, having visited the bathhouse once, fall in love with it for life. Which is understandable - the bathhouse is an amazing complex, regular visits to which can not only improve your health and get rid of a number of chronic diseases, but also get considerable pleasure. Research shows that people who go to a real Russian bathhouse at least once a month are less likely to suffer from diseases of the airways, joints, infectious diseases and common colds.

Layout of a wooden bath 4x4

But in order for visiting the bathhouse to bring only pleasure, you need to carefully think through everything down to the smallest detail. It is necessary to calculate the optimal size of the bathhouse and the location of the premises, and also draw up the correct plan.

The most popular today are baths measuring 4x4 meters. Why do thousands of our compatriots prefer bathhouses with these dimensions?

How to choose the appropriate log size

Choosing the size of a log house is always a search for a compromise that would suit you in all respects. Therefore, when choosing the appropriate log size, you need to consider the following factors.

- Exactly how much area of the plot are you willing to allocate for development? Very often, owners of small plots of about 6 acres are forced to take this issue very seriously.

- Construction cost. It is quite clear that the larger the dimensions of the log house, the greater the amount will have to be allocated for it.

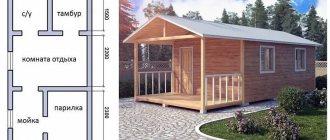

Layout option for a 4x4 bathhouse with a veranda

So a log house measuring 4x6 meters can cost 10-12 thousand more than a log house measuring 4x5 meters. For many people, these savings will be quite noticeable.

- The time required to heat the bathhouse. Every person understands that the larger the area of the bathhouse, the more time and fuel will have to be spent in order for the temperature in it to rise to the desired level.

- The number of people who will visit the bathhouse. This is a very important parameter. If one or two people will go to the bathhouse, then a small bathhouse measuring 3x3 meters is quite enough. But if you have a fairly large family or guests regularly come to you to enjoy the pleasure that only a real bathhouse can give, then it is better to think about a more spacious log house so that your bathhouse can easily accommodate everyone.

- Bathhouse layout. Think seriously in advance about exactly how many rooms you need and what area they should have.

An example of the layout of a large bathhouse with a swimming pool

For some people, a tiny bathhouse is enough, consisting of a small dressing room where the firebox is located, as well as a steam room combined with a washing room and toilet. Others dream of a spacious dressing room, where you can install a table and benches, as well as a separate steam room and washing room. You can also build a bathhouse with an attic. Only after deciding what is the best option for you should you move on to choosing a log house.

As you can see, choosing a log house can be associated with many difficulties and calculations. However, in most cases, baths measuring 4x4 meters fully satisfy all requirements, being a good compromise. On the one hand, it is relatively inexpensive and does not take up too much space on the site.

On the other hand, a bathhouse of this size can be heated quite quickly. And if the layout is calculated correctly, the bathhouse can easily accommodate all the rooms necessary for a comfortable stay. It would be useful to study the last point in more detail.

Project of a bathhouse with an artificial pond

Conclusion

The size of the bath does not affect its benefits. By properly planning the space, you can achieve its maximum functionality. The project plays a major role in this matter - it contains all the information about what the bathhouse will be like, the materials for construction and finishing, a clear interior plan (see also the article “Project of a 4 by 4 by 5 bathhouse - on “medium” sizes, like and in the “middle” class, everything holds up”).

The video in this article will tell you in detail about the features of medium-sized baths.

Did you like the article? Subscribe to our Yandex.Zen channel

What rooms can a bathhouse consist of?

So, you decided to build a bathhouse using a log house measuring 4x4 meters. What rooms should it be divided into? Most owners of such log cabins settle on three rooms that they consider the most important: a dressing room, a washing room and a steam room. A variant of the 5x5 bathhouse layout where the firebox is located in the dressing room, in the far corner, through the wall separating the dressing room from the steam room. This can truly be considered the most successful option.

You get a fairly spacious dressing room 4 meters long and 1.5 to 2 meters wide. Of course, you can place benches and a hanger here to leave clothes before entering the washroom. Often in the middle of the dressing room there is a not too wide, but elongated table and one or two benches.

Thanks to this, after going to the bathhouse you can relax in a fairly large group (up to 6-10 people). Many bathhouse owners highly value this communication - especially relaxed and comfortable.

An example of the interior design of a wooden bathhouse

From the dressing room the door should lead to the washing room. This will prevent excessive heating of the dressing room and heat loss. At the same time, it will always be warm enough in the washing room itself. The washing room can have a width of 2-2.5 meters and a length of 1.5 to 2 meters. True connoisseurs of baths prefer to allocate a little less space for the washing room in order to gain an extra square meter for the steam room. After all, most of the pleasure you can get in a bathhouse comes from the steam room.

The layout of the steam room must be carefully verified. Seriously think about what shape and size of shelves will suit you. Some people prefer a regular shelf, while others prefer a corner shelf. The first option allows you to get more free space in the steam room, while the second allows more people to visit the bathhouse.

Layout of a 4x4 sauna located in the basement of the house

The width of the steam room is usually 2-2.5 meters, and the length is from 2 to 2.5 meters. Of course, part of the area needs to be allocated for the stove and heater. It should be located in a corner, but not close to the wall.

This reduces the risk of fire on wooden walls or cladding, but also saves the usable area of the bathhouse.

It is better to make the shelves at least 0.7-1 meters wide, so that you can not only sit on it comfortably, but also lie down while hovering.

Additional services

- Replacing timber 150x100 mm with timber 150x150 mm RUB 22,000.

- Replacing timber 150x100 mm with timber 150x200 mm RUB 36,000.

- Wood-burning stove Ermak from RUB 52,000. (more details)

- Increase the height of the bathhouse by one crown (+15 cm) RUB 16,000.

- Construction of partitions from timber (150x100 mm) RUB 22,000.

- Coating of joists and subfloor (as a gift: promotion until December 31) 400 rub/m²

- Replacing a 27 mm floorboard with a tongue and groove board 36 mm thick 380 RUR/m²

- Metal entrance door (China) 7,000 rub.

- Bathroom insulation up to 100 mm 350 RUR/m²

- Warm corner (as a gift: promotion until December 31) RUB 24,000.

- Assembling a bathhouse on wooden dowels RUB 24,000.

- Cladding the stove with bricks (as a gift: promotion until December 31) RUB 8,000.

- Construction shed 3x2 m. 19,000 rub. (more details)

- Roofing (metal tiles) 990 RUR/m²

- Finishing the gables of a block house RUB 1,200/m²

- Generator rental (customer’s gasoline) RUB 9,000.

Floor

We insulated the floors in the bathhouse. The steam room and shower have tiled flooring, and the dressing room has laminate flooring. First, I’ll tell you about the steam room and shower; there are many more important nuances there.

Laying tiles

The tiles were purchased with a matte finish and rough so that they would not slip. We decided that tiles are much better than wooden floors - they don’t rot and are easy to clean. The glue was purchased with the best moisture resistance characteristics.

Waterproofing was laid on the subfloor, overlapping the walls. On top of the waterproofing, insulation was laid - EPPS (thickness 30 mm). For better adhesion of EPS to the waterproofing, assembly adhesive was used.

A screed was poured over the insulation along the beacons with a slope towards the drain funnel. Before pouring the solution, a reinforcing mesh and a set of beacons were laid. The photo shows that we attached the beacons not to the floor, but to an asbestos solution - we laid out piles and pressed profiles into them. The solution (cement with sand) was mixed in a rented concrete mixer, because

It was important to fill the entire floor in one day. The solution was laid out from the bucket with a trowel onto the grid between the beacons and leveled with a wooden plank - the rule

The floor was finally leveled with a wide trowel and grout.

The tiles were laid away from the drain gutter to make it easier to maintain the slope. Each one was pre-soaked in water. The glue was applied with a notched trowel onto the dried and primed screed. In this case, glue was not applied to the entire surface of the floor at once, but only to the space for laying 1-2 tiles. The glue hardens quickly and should not be used to cover a large area of the floor at once. The thickness of the adhesive layer was kept approximately equal to the thickness of the tile. I collected the excess glue around the laid elements with a simple narrow spatula.

First, all rows of whole tiles were laid out, then parts along the walls. We cut the tiles with a manual tile cutter. By the way, for precision masonry we pulled the fishing line and used crosses for the seams. And for better contact of the tile surface with the binder, immediately after laying, I lightly tapped each square of tile with a rubber mallet.

Laminate

The laminate flooring was installed very quickly. We covered the floor with film over the insulation, nailed down moisture-resistant plywood, and rolled out the backing.

I unpacked the package with a knife. He took out the first panel and laid it down, turning it with a small protrusion towards the wall. I inserted 2 plastic wedges between the wall and the board. I took the second strip and snapped it into the end groove of the first. I leveled it and placed the wedges again. When I reached the opposite wall, I used a circular saw to cut off the extra piece of the laminate panel. The next row began from the segment. The second row was assembled in the same way as the first, after which I lifted the entire floorboard at an angle of 45 degrees and carefully connected it to the latch of the first row, and then hammered it through the block with a mallet. The last row had to be sawed lengthwise, precisely measuring the cutting line.

Drain arrangement

The arrangement of drainage from existing water intakes must be taken care of at an early stage of construction of the bathhouse.

Drain arrangement

Firstly, it is necessary to lay a sewer pipe with a slope of 1 meter 3–5 cm. Such a pipe should come from the shower and from the water drain tap from the pipeline system. It is located at the lowest point of the pipeline. Such a tap is needed to drain water from the system and preserve the bathhouse for a long period, for example, throughout the winter. It is better if the drain pipe does not have branches or turns. A straight pipe is a way to avoid blockages. The diagram shows how best to connect two water intakes into one system.

Making a gasket for a sewer pipe

Pipe system

Draining

It is better to connect the sewer pipe to the septic tank so that the drain water does not go into the ground.

Differences and features of technologies

Frame

- The supporting structure is a wooden frame on which all building elements are attached. The bathhouse is installed on the site without the use of equipment. This is 100% handmade. It is possible without the involvement of specialists.

- When designing a frame bath, any customer requests are taken into account. The only restrictions are regulations.

- Quick commissioning of the facility.

- Frame baths, including mobile ones, have the most affordable price. The cost can increase: a) increasing the size of the bath; b) type of foundation; c) expensive materials for interior and exterior decoration; d) type of insulation; there are recommendations for insulating the roof, walls, floor and ceiling of the bathhouse; e) independent work or with the involvement of specialists; f) engineering additions...

- They are strong and reliable. A large number of stiffening ribs prevent the structure from deforming.

Frame-panel

1) The production of frame-panel baths is a complex, expensive process. The main structural element is SIP.

The design of SIP (structural insulated panel) is similar to a sandwich. Between two sheets of wood-based material there is a thermal insulation layer.

There is a wide variety of SIPs on the market. But, since you are interested in a bathhouse, then look for a sandwich where the outside is oriented strand boards with the abbreviation OSB, and the inside is polystyrene foam.

The middle layer binds the entire structure together using a special high-pressure adhesive (cold pressing). The wood leaves are strictly parallel. Waterproof treatment of slabs is carried out during their manufacture.

Individual design is not possible. Always a ready-made standard design solution.

2) This bathhouse is assembled quickly (2-3 days). All blocks and elements are clearly adjusted to each other in the factory.3) The cost of frame-panel technology increases due to:

- expensive production;

- attraction of lifting equipment;

- possible increase in the number of construction crews.

4) The panels are attached to each other using a wooden beam, the selection of which requires special attention, according to the “tongue and groove” principle.

The joints are sealed with polyurethane foam. Vertical and horizontal bars provide additional rigidity and stability.

5) Panels can last more than 50 years.

Advantages and disadvantages

To appreciate this technology, let’s watch a video from a well-known channel, and then look at its pros and cons.

pros

- Fire resistance: the panel is capable of holding back fire for an hour, the ANTI-FIRE treatment is effective.

- The panel material is non-toxic and safe for humans.

- The panels can withstand heavy loads: everything can be mounted on them, even heavy hanging furniture.

- SIP walls are thin, but retain heat well.

- Smooth walls inside and out: any finishing materials.

- Resistant to temperature changes. Build baths all year round!

- SIPs are excellent sound absorbers.

- Thermal losses of sandwich structures are minimal.

- Moisture resistance: SIPs do not rot, mold does not form on them.

- Seismic resistance: buildings can withstand vibrations of more than 5 points.

For your information! A frame-panel bathhouse is more expensive than a frame one, but half the price of a log house.

Choose frame-panel baths to suit any budget:

Turnkey (cladding of facades and internal walls is carried out at the sandwich panel manufacturing plant); Rough finishing (decoration either inside or outside - at the customer’s choice); Without finishing (the customer carries out internal and external finishing on his own).

Photo of the company ProSIP (St. Petersburg)

Minuses

The service life is limited to 50 years. When heated above 125 degrees, the thermal insulation layer burns and deforms. External uniformity and unattractiveness of objects without finishing. Violation of technology leads to loss of strength.

VERY IMPORTANT! Lay the electrical wiring correctly, paying special attention to the areas where sockets and switches are attached. A spark may cause the inner layer of the sandwich to ignite. For the same reasons, use non-combustible materials for finishing.

ATTENTION: seal all cracks and gaps, otherwise all the thermal insulation will be damaged by rodents.

Straight to the point: don’t confuse technologies!

If you think that a frame-panel bathhouse is the same as a frame bathhouse, just a more detailed and longer name, then carefully read the following sentences. A frame-panel building is built from ready-made panels, which are purchased from companies that professionally deal with them. A frame building can be built by any home craftsman with minimal construction skills and tools. The frame is erected, filled with insulation, sheathed and finishing work carried out. If you need such a frame bath, then go to the appropriate section. If you are still sure that you need information on panel buildings, then read on.

Photo: VIVA HAUS company

Construction of a foundation for a country frame-panel bathhouse

The usual construction of a strip foundation for a building requires 1/3 of the total financial costs for construction and the same amount of time. Due to the fact that our construction will be lightweight, the foundation can be carried out according to a simplified scheme, but a strip or pile structure would lead to an unreasonable increase in the cost of the entire construction. We will make the supporting part of the frame from “bald” car tires filled with crushed stone. After construction is completed, the tires should be protected from sunlight. This will prevent them from breaking. Features of constructing a foundation for a bathhouse in the country:

- After breaking down the perimeter of our bathhouse, the plant layer of fertile soil is cut off from its inside and carefully moved to the garden. As a result of this procedure, you should get a mini-pit 3.5x5 m with a depth of 0.15 m.

- Its bottom is compacted by rolling a heavy steel barrel over it. Then the entire area needs to be covered with fine crushed stone and also “rolled”. As a result, we received a dense crushed stone cushion for the bathhouse in the country, which in the future will evenly distribute the entire load from the structure.

- It is necessary to hammer one peg into the places where the tires will be installed.

- Then the tires are laid throughout the area so that the center of each of them coincides with the peg. The future foundation must be leveled in a horizontal plane. For this, a flat board 4 m long and a building level are used.

- After all the tires are leveled, a pad of any waterproofing material is placed inside each of them to prevent rubble from spilling out when working with the tires. All tires are covered with crushed stone in layers, with each of them compacted.

- Backfilling must be stopped before reaching the edge of the inner rim 5 cm. The crushed stone inside the tire is moistened, and its entire internal cavity is filled with Knauf cement mixture with the addition of filler. Thus, all lying tires should be filled to the very top at the same level.

- After polymerization of the concrete mixture, we obtain a durable layer in the rubber “formwork” that transfers the load to the crushed stone cushion. The rubber of tire beads serves as a compensator for periodic freezing and thawing of the soil.

As a result, when constructing such a foundation, we almost avoid excavation work and have a small consumption of materials: car tires d = 70 cm - 10 pcs., crushed stone - 3 m3, KNAUF mixture - 75 kg, roofing felt - 1 roll. The beam of the lower trim of the frame is installed on supports made of tires.

Flaws

In addition to many advantages, when constructing a frame building there are also some disadvantages:

- The construction of the building itself requires little money compared to other buildings, but it requires considerable cash injections for finishing and insulation (insulation may be inexpensive, but membrane films also cost money;

- The process of closing the insulated frame should be completed within 1.5 - 2 weeks (or even faster, until the insulation gets wet and is not torn by the wind);

- The impossibility of using inexpensive cotton wool and polystyrene foam for insulation (this is a plus about environmental friendliness);

- Finishing with slabs is not recommended in most cases; a ventilated façade is needed.

High cost of finishing

As described earlier, despite the seemingly cheap construction of a bathhouse at first glance, its finishing requires significant costs. Finishing, both external and internal, is the most expensive of the entire process of building a frame bath.

Requirements for the quality of insulation

The disadvantage of the “frame” is the impossibility of using cheap materials as insulation. Only high-quality and therefore more expensive insulation options are suitable.

We also recommend reading the following materials:

- Insulation of the walls of a frame bath;

- Insulation for the walls from the inside and what kind for the steam room;

- Which insulation is better, and also about foil and foil.

Speed Requirements

The construction takes a little time from the developer, but requires proper treatment (the insulation must be closed, otherwise it will get wet - as a result, you will have to buy it a second time, since it can be easier to throw it away than to dry it).

Ventilation requirements

Ventilation is simply necessary for frame construction. Ventilation maintains the necessary microclimate in the building at any time of the year. Unlike hygroscopic wooden walls, frame walls with their vapor barrier create the effect of a “plastic bag” in the bathhouse, similar to a greenhouse or greenhouse. It quickly becomes hot, but at the same time stuffy, you can simply suffocate if there is no ventilation.

We recommend reading about ventilation: in the steam room, diagrams and design, how to do it correctly.

Vapor barrier requirements

The bathhouse requires masterful work with membrane film. If the insulation is carried out with breaks or the joints are poorly sealed, the insulation will get wet and simply stop working.

Shrinkage

The insulated frame must be “closed” within two weeks. The actual shrinkage of raw lumber or “natural moisture” may take a slightly longer period. When the frame boards dry out, construction defects may appear: cracks, film breaks, and cold bridges may appear.

Weakness to wind and snow loads

Despite the fact that the frame is resistant to seismic activity, it is weak against snow and wind loads. The consequence is that the frame should be built in certain areas of the country where these weather conditions are least likely to manifest themselves or allowances should be made for them, which will increase the cost

This disadvantage should definitely be taken into account by everyone who wants to build a frame building.

Fast cooling

Despite the fact that the frame warms up faster, it cools down no slower than its “brothers” (stone, wood), but rather even faster. The reason is the same low heat capacity. The beam, log, stone must first be heated, while the “plastic bag” of the frame does not heat up, but only the air in it heats up. But even when the furnace stops, this air cools down quickly (after all, we will do ventilation, where without it, see above), and massive traditional materials can release the accumulated heat for a long time.

When choosing, you should take this fact into account.

Important features when constructing a frame bath

A frame bath requires high-quality thermal insulation. Mineral wool or basalt is suitable as a thermal insulation material; fiberglass insulation is also suitable.

An important point is vapor barrier. In rainy weather, and in winter during snow, moisture enters the bathhouse through cracks, forming condensation inside the frame, as well as on the walls and ceiling. To cope with this problem, hydro- and vapor barriers are used.

Wood for a bath should be selected well dried, because when the wood dries out, it decreases in volume and cracks appear. The best option for a bathhouse is larch, aspen or linden.

Selecting a frame bath project

On long winter evenings, we outlined the plan for our future bathhouse.

Photo of the frame bathhouse project we settled on.

Before choosing the material for building the bathhouse, we consulted with the builders for a long time. On their advice, we chose a standard design for a frame bathhouse installed on a pile foundation. This choice is due to the fact that groundwater in our area comes very close to the soil surface, and heaving soil can cause walls to crack if we use brick as a building material. Even if we use a strip foundation reinforced with piles, we still cannot get a 100% guarantee that it will withstand seasonal ground fluctuations.