Today, for many developers, building a log house is not just a continuation of the age-old traditions of their ancestors, but a desire to obtain environmentally friendly and energy-efficient home ownership.

In order for the tree to work as fully as possible to create favorable conditions for living in the house, you need to correctly select the sizes of logs for the structural elements of the house: external and internal load-bearing walls, floors, ceilings and roofing.

The dimensions of the logs influence many indicators of the finished house building, but most of all its heat-insulating characteristics, the final price of construction and the external appearance of the building. Having chosen the diameter of the round timber, you need to be prepared for the fact that in fact the supplier may supply the cross-section of the products by 2-3 cm smaller.

How to choose the best one

The desire to buy a huge log house for a bathhouse is understandable; you want everything at the same time: a large steam room, a washing room with a shower, a room for family or friendly gatherings, a place to relax on the second floor... The list goes on and on. But then the oven intervenes.

How long does it take to warm up the steam room to operating temperature? How much fuel is needed to heat rooms? Practical owners begin to count and limit themselves in their desires and settle on a standard log house width of 3 or 4 meters.

Next, a puzzle is solved with the location of the main blocks: steam room, washing room, locker room, rest area.

FUNDAMENTAL question

The bathhouse is built on a special foundation made of stone or concrete.

By design, foundations are divided into strip foundations - in the form of continuous walls and columnar foundations - in the form of separate support pillars. The depth of foundations depends on the depth of the soil layers taken as the natural foundation. In clayey and loamy soils, which have the property of swelling when freezing, the base of the foundation is placed below the soil freezing level by 10-25 cm. In non-heaving soils, which include sandy and gravelly soils, the foundation depth does not depend on the freezing depth and is no less than 0.5 m from the planning mark. For internal walls it is less than for external ones, but not less than 0.5 m from the ground level.

Strip foundations are made from irregularly shaped natural rubble stone with cement mortar or from rubble concrete and concrete (a cement mortar of 1:3 composition (1 part cement and 3 parts sand) is used to level the top.

It is advisable to dry the leveled and smoothed cement mortar, and put waterproofing on top of it on mastic from two layers of roofing felt or roofing felt (roofing felt on tar, and roofing felt on bitumen mastic). The thickness of the strip foundation depends on the size and design of the bathhouse and can vary from 250 to 500 mm.

Columnar foundations are usually made for wooden baths with light loads in the form of individual stone or brick pillars measuring 380 x 380 mm. The pillars are placed at all corners of the structure and at the junction of the internal walls with the external ones. For large baths, intermediate ones are installed between the main pillars so that the distance between adjacent ones does not exceed 2 m.

Which height do you prefer?

Centuries of experience have shown that the universal ceiling height in a bathhouse is 2.2 m. This means that when choosing a log house you should not listen to the manufacturer’s reasoning that small dimensions will help save heat. Please note that:

- floor joists cut between the second and third crown (0.35 cm of total height is lost);

- the attic floor is installed in the penultimate crown (minus 0.16 m);

- the thickness of the floorboard is from 3 to 5 cm, and the lining on the ceiling is about 2 cm;

- The shrinkage of the building is usually 1 cm from each crown (minus another 0.15 m).

Attention! Taking these design features into account, it turns out that the bathhouse frame needs to be selected with a height of 2.9-3.0 m.

Steam sitting or standing?

The uneven distribution of steam in the room allows people of varying degrees of preparation for high-temperature conditions to take the procedure. The standard for a steam room in a Russian bath is shelves with three levels:

- lower – pre-heating, adaptation to extreme temperatures, level 0.4 m;

- medium – height 0.7 m or up to the palms of the steamer standing on the floor;

- the upper one is located 1.1 m from the finished floor for the convenience of the steamer standing on the first step.

There should be 1.1 m left from the top level to the ceiling so that you can still steam yourself by fanning your back with a broom from above with a bent arm.

Dimensions of the steam room and the location of people in it.

This results in a recommended ceiling height of 2.2 m minimum. Moreover, this size takes into account only the operating conditions in one room; the floor level in other rooms differs from the steam room.

A bathhouse with low ceilings cools down faster, perplexing inexperienced developers. The reason for this is trivial: the steamer standing on the bottom step, using a broom, disperses the air concentrating in the upper part of the room, thereby cooling it. That is why an additional 20-30 cm of height will help maintain a supply of steam at the ceiling.

A bent back at the waist while steaming or washing can negate the entire therapeutic effect of the bath. The impression will be spoiled, the user will not agree to log in again. It is much easier to reduce heat loss by installing an insulated internal frame than to save on the convenience of family members and guests.

Log houses 3 meters wide

If you want to save money, you can abandon the rest room and even the washroom, and replace it with a small locker room or even a vestibule. And you can’t do without a steam room. When planning this room, the following factors are taken into account.

- The stove is located next to the door and usually occupies a usable area of 0.7x0.7 m2.

- The length of the shelf for a recumbent is 220-230 cm, width 80 cm (minimum 70 cm).

- The width of the seat shelf is 40 cm.

- The steamer should stand comfortably with a broom and mark the gap from the walls and stove.

It turns out that the optimal size of the steam room is 2.5 m x 2.5 m, and the minimum is 3.0 m x 1.5 m.

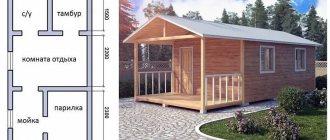

Layout option 3 3 m

In such a log house you will have to plan only the essentials. The total area of the premises is about 9 square meters. Part of the area is eaten up by internal insulation and partitions. The stove is installed in the corner farthest from the door.

Instead of a spacious dressing room, they leave a small dressing room with a hanger and a bench for changing clothes, and if necessary, take a break after the heat of the steam room. Based on the fact that the minimum area of the steam room is 5 m2, it turns out that it is convenient to plan a log house of a 3x3 m bathhouse in this way:

In this layout, everything is harmonious: the doors are arranged in one place, the stove is located in the far corner (which reduces heat loss).

The firebox is located in the dressing room; a partition divides the room into two approximately equal parts.

Behind the door in the steam room, an additional bench fits well, with a place for washing.

But, whatever one may say, this is a very miniature project, for a small family that uses the bathhouse occasionally, only for its intended purpose.

In order not to feel the lack of space during the warm season, you can attach a veranda to such a bathhouse.

Layout option 3x4 m

An area of approximately 4.5 square meters is also allocated for a steam room for two or three people. The partition is placed 150 cm from the wall. The layout of the steam room will be similar to the previous option. And for the rest room, with this arrangement, almost 7.5 m2 will remain. You can put a small table or chair for relaxation.

If it is more important for you to increase the area of the steam room or there is a need to allocate more space for the washing room, then it makes sense to plan the partition at a distance of 200 cm. With this layout, the canopy can be arranged at an angle; with a length of 2 m, even a tall person can stretch out to his full height. And four can sit comfortably. The stove with heater and hot water tank will be located at a safe distance from people.

Information. Shelves on three levels allow you to choose different temperatures for those in the steam room.

- On the low shelf there is a pre-heating stage, getting used to the hot microclimate. Level height 0.4 m from the floor.

- Medium level for warming the whole body. It is placed at a height of 0.7-0.9 m or to the waist, which stands on the floor.

- At the upper level there is a soaring zone, where the highest temperature and heat are concentrated. Here you can sit or lie. The standard step height is 1.2-1.4 m from the finished floor. Or take a distance from the ceiling at which it will be convenient to swing a bath broom.

Layout option 3x5 m

A log house for a bathhouse with an area of 15 m2 cannot be called economical. To heat it, you will need more firewood, but the interior will be more comfortable. With a log house length of 5 m, it becomes possible to plan a separate washing compartment. Let's take a closer look at this location option:

By installing the partition perpendicular to the three-meter wall, you get a separate washing compartment and a large steam room with an area of 8 m2.

The 1.85 m long canopy is placed along the wall, or can be laid out at an angle.

The stove is located in the steam room, but the firebox is located in the rest room. 7.5 m2 will accommodate a hanger, benches and a sofa.

At low cost, a bathhouse measuring 3x5 m will satisfy the needs of a budget-conscious family of 4-5 people.

If desired, you can add a veranda, then in the summer you can drink tea from a samovar or cold kvass right in the fresh air.

Please note that the frame of a 5x3 bathhouse can be easily enlarged by building an attic roof. This solution has several advantages: an additional room with a place to relax, a small porch, economical use of materials. The interior contents of the premises will look like this:

Layout options 3x6 m

The figure shows a fairly traditional arrangement of rooms in a bathhouse. The stove is fired from the washing compartment. All parts are approximately the same volume:

It practically copies the layout of a transportable mini-bath, because this is the only relatively convenient solution in this case.

But the large area of 18 m2 allows you to get creative and design the interior in other ways.

For example, place the partition between the shower and steam room perpendicular to a three-meter wall.

Depending on the position of the stove, in a log bathhouse 6 by 3 m, you can plan the following options:

Why is it important to choose the right one?

The size of the logs during the construction of any building primarily determines the strength and heat-insulating characteristics of the home, its final cost and the external appearance of the structure.

The most important from this list are strength and thermal insulation characteristics . They are ensured by the thickness of the wall and careful caulking of the roof joints.

For the first characteristic of a two-story house with an area of up to 250 m2, logs of 250 mm are sufficient, but for the second, at least 300 mm, and for the northern regions, more than 400 mm. The preservation of heat in the house and the costs of the heating system will depend on this. The thicker the log, the cheaper the heating.

An additional advantage of using dimensional logs is that fewer of them will be required during construction, and accordingly there will be fewer connections through which the cold will penetrate.

In addition, an increase in the cross-section of the timber shifts the “freezing” limit of the wall , increases the frost resistance of the log house and, as a result, increases the overall service life of such a building.

However, increasing the diameter of the wall material increases the cost of construction of the project, since not only the cost of timber increases, but also the cost of laying it, shipping bills and loading and unloading labor.

Log houses 4 meters wide

Perhaps the greatest scope for imagination is provided by log houses with a width of 4 m. Here, initially it is possible to place the partition parallel or perpendicular to the far wall. The internal arrangement of the stove and premises can be varied, the area of the necessary objects can be increased or minimized.

There is enough space for a steam room, a sink, and a massage table in the relaxation room.

Information. If desired, in a 6x4 log house for a bathhouse you can already plan a staircase to the second floor and arrange a small sleeping place or an additional rest area in the attic.

4x4

With a total area of about 16 m2, a room of 6.25 m2 can be allocated for a steam room. The remaining squares will accommodate a table and benches that can easily accommodate a company of 5-6 people. Unfortunately, in order to make an attic in the log house of a 4 4 m bathhouse, the stairs will most likely have to be taken outside - otherwise the area of the rest room will be greatly affected. Let's consider layout options for other sizes.

Layout 4x5 m

This placement has its advantages.

The stove is heated in the corner by the door, there is no need to stomp around the room.

There is a large room of 11.5 m2 for relaxation.

Here you can organize a undressing area and a table with benches.

If desired, the bathroom can be changed to a washroom with tubs and gangs traditional for a bathhouse.

The log house of the 5x4 bathhouse itself can be supplemented with an attic or a covered terrace or a wide porch can be added.

Why do we need multi-level floors in a bathhouse?

The choice of ceiling height for any room is influenced by the floors. The operational features of the bathhouse are:

- periodic intense heating followed by ventilation to ensure maximum service life of structural materials, cladding, made in 95% of cases from wood (timber, calibrated logs, boards, lining);

- uneven temperature conditions in the rooms (maximum heat in the steam room, average heating in the washing room, coolness in the rest room/dressing room);

- high humidity, plenty of water in the washroom.

Layout of the floor with lining.

Based on this, the floor of the steam room should be 0.2-0.3 m higher than the adjacent washing room, so that when the door is opened, cold air penetrates minimally into the room with the heater. To prevent water from flowing into the rest room, the floors in the dressing room are also raised to the specified height. Thus, the level of the floor covering of the lowest washing room in the building is directly an indicator of the ceiling height in the steam room.

Installation of floor joists and attic floors at different levels requires high qualifications.

An excessively high ceiling in rooms equipped for relaxation between steam procedures will require an increase in the power of the sauna stove. Thus, specialists will be required to produce a high-quality project.

To increase the comfort of functional premises, it is wiser to provide unheated storage rooms and rooms for storing fuel.

By lowering the level of the ceiling cladding to save firewood, quickly reach steam mode, and keep it in the room for a long time, users often experience discomfort:

- during paired procedures it is necessary to breathe something;

- in a low room there is excess humidity, which is not comfortable for the lungs;

- therefore, it is better to increase the level of the ceiling.

Width 6m

With a 6m long wall of the bathhouse, you can easily accommodate all the necessary rooms: a steam room, a washing room, and a relaxation room. Many people also make an attic, expanding the usable area of the building.

Options 6 by 4 m

The most popular size of a log bathhouse is 4x6 m. This option is already suitable for a large family. It is ordered quite often. If you carefully study the projects, it will become clear why: such a bathhouse can comfortably accommodate from 4 to 8 people.

Interestingly, the customer can determine the location of the fifth wall independently.

If you want a standard steam room, aim for a distance of 150 cm from the wall.

If you want a large steam room and washing area with a shower, sink, and toilet, move the wall 250 cm.

With this option, a large stove is installed, the room warms up quickly. The rest room in the log house of the bathhouse is 4 by 6 m, even with this arrangement it turns out to be small - 13.4 m2.

If your plans include inviting large companies with a mandatory visit to the steam room, then you will have to think about a log house with a width of 6 m. You can increase the dimensions of the building endlessly: add a terrace, arrange a veranda with a winter garden, a second floor, an attic with a balcony under the roof... Log houses with a width 6 m allows you to perform such manipulations.

Wastewater disposal

When building a bathhouse, it is best to divert water outside the bathhouse and the farther the better, but at least 2-3 m.

It is best to discharge water into a centralized or local (local) sewer network. In its absence, water can be diverted to a ravine or other place, while observing sanitary supervision standards. For water drainage, it is best to use cast iron, asbestos-cement, ceramic and concrete pipes. It is possible to use modern PVC-based materials. It is not recommended to use wooden pipes (boxes) or steel pipes, they quickly rot, and steel pipes are destroyed by rusting.

Drain pipes with a diameter of at least 50 mm are assembled into a ladder box made of steel or concrete with a pipe raised 19 cm from the bottom. An inclined metal plate is installed in the ladder, not reaching the bottom by 5-6 cm, and is hermetically fastened to the wall from the sides and top. The top of the ladder is covered with a grille-lid with holes. This creates a water seal that prevents odors from rotten water and cold air from entering the bathhouse. To prevent water from freezing in the drain, it must be removed after washing. The joints between the pipes are covered with cement mortar.

Advice from Ivanovich

Our expert, an experienced builder and a seasoned bathhouse regular, Yuri Ivanovich, reveals secrets that are worth listening to.

- Don't overpay for the foundation. This construction is quite light; traditional monolithic pillars and a good sand bed 40 cm deep are quite sufficient.

- Do not settle for a ceiling height of 180 cm. Such a bathhouse is not cozy and cramped. The minimum ceiling height should be 210 cm. It is better to order a log house one or two crowns higher.

- Do not cover the roof with roofing felt; use durable, modern material right away.

- Cut out openings for windows and doors after the frame shrinks, after a year. And it will be easier to move whole logs for felling. If you really need it, cut a passage three or four logs high.

A bathhouse furnished with your own hands is an excellent proof of the owner’s wealth and a cozy place to relax. After completing the troublesome construction, you can rest peacefully for years, relaxing your soul and body.

Where to place it?

The ideal place to build a bathhouse is a gently sloping bank of a river, lake, or pond, protected from the wind by trees. If the bathhouse is part of a system of outbuildings, the distance between it and other buildings for fire safety reasons should be at least 20 m. In residential buildings and summer cottages located outside densely populated areas, the bathhouse can be built under the same roof as the main building. It is also necessary to provide for the possibility of draining contaminated water, so it is better to locate the bathhouse in an elevated place - the possibility of minimal deepening of the sewer tray.

In ancient times, a settler who came to live in a new place began the development of the site by building a bathhouse, in which the family lived the entire time necessary to build the house. A city dweller who is developing a garden plot can now do the same: build a temporary building - a bathhouse and live in it until the construction of the house is completed.

Log houses

Design

When choosing which log house is better - from timber or logs - they often settle on the more traditional option. What are the features of log structures?

Logs have been used as a building material for a very long time, but rounding is a relatively new technology. This type of processing provides a significant increase in the strength of the structure being built, since during cylindering the most loose parts of the tree trunk are removed.

Houses built from logs are characterized by high strength and significant thermal insulation properties. The connection of individual elements into a log house occurs through special grooves and crown cups, which (of course, subject to high-quality manufacturing) allow minimizing gaps.

Note! As a rule, for the construction of a house, a separate set of logs is made, with grooves and bowls in the appropriate places.

Advantages and disadvantages

The advantages of buildings made of this material are as follows:

- If the log house kit is manufactured with sufficient accuracy, assembly does not take much time. At the same time, labor costs for craftsmen are significantly reduced.

- Installation of a log house can be done with your own hands, especially if there is an experienced mentor nearby or at least detailed instructions.

- Connecting the logs together ensures sufficient tightness of the building. At the same time, heat transfer resistance can be increased through the use of effective sealing materials.

- The attractive appearance of log walls makes additional finishing unnecessary. Perhaps it is for this reason that when thinking: “A bathhouse made of timber or logs - which is better?”, many choose the second option.

As for the disadvantages, they are as follows:

- Significant shrinkage. Since the log is a natural material, in terms of deformation it is significantly inferior to laminated veneer lumber. The “box” of the building must stand for at least a year before finishing work begins.

- If you decide to finish the interior walls, you will have to suffer, since the sheathing will need to be attached to an uneven surface.

- Another drawback is significant flammability. The threat of fire can be reduced by impregnation with fire retardants, but the building will not be completely safe.

- Also, the log, especially its ends, is very susceptible to external influences. If you neglect protective treatment, then within a few years the log house will lose its attractive appearance.

To summarize, I would like to note that the last two disadvantages will also be characteristic of timber. But strong shrinkage and complexity of interior finishing are disadvantages specific to logs. They must be taken into account at the planning stage.

Cutting methods

There are three main cutting methods: cup, paw or dovetail. When choosing a cup, you will get windproof, very warm corners and a durable frame. Disadvantages include a reduction in the internal area of the room and a high consumption of wood. The logs will need to be punched very tightly if they are felled in the summer. This is done to prevent the walls from sagging in the middle.

Cutting with a paw or a dovetail is practically the same thing. Over time, such a log house will only become stronger; thanks to its shape, when it subsides, it contracts. However, the corners of such a house need to be insulated somehow, as they are heavily ventilated. Usually they are covered with boards or insulated with special panels.

A log house made of rounded logs cannot be called a log house at all; they have not even touched it with an ax. What you need to know about this lumber is that the timber must be from the northern regions, because when processing logs in central Russia, the sapwood, the hardest and most valuable layer, is almost completely removed. Without it, the house will quickly rot and collapse.

Features of materials

Before deciding what is better for your home - a log or timber, it is worth spending some time studying the materials themselves.

- A rounded log is a tree trunk, cleared of bark and branches, which was given a certain shape during processing. During the cylindering process, the workpiece is aligned in diameter, and at the output we have an almost ideal cylinder.

- Today, blanks of construction logs are impregnated with an antiseptic immediately after production, which provides the structures being built with resistance to the effects of fungi and bacteria.

- In contrast, the workpiece can also be subjected to profiling, in which locks are formed on the lower and upper planes to more effectively connect the parts to each other.

- If the log is most often solid, then it is made from several strips of wood. In this case, for the production of the material, pre-dried and antiseptic-treated boards are used, which are connected to each other with a resin-based adhesive.

However, external differences and design nuances are not everything.

You can see the difference between materials only by analyzing the features of their use in construction.

Ceiling

The ceiling of the bathhouse is made of planed boards, tightly fitted to each other. To preserve heat, steam and thermal insulation is installed on top of the boards. The easiest way to make a vapor barrier is to apply a 1.5-2 cm thick coating of clay on top of the boards. For insulation, use mineral wool or backfill with wood chips moistened with a cement solution in a ratio of 8:1, 15-17 cm thick. A lime-coated layer is placed on top of the insulating backfill. sand screed or backfill with sand (earth) at least 20 cm thick. The thermal regime of the steam room largely depends on the quality of the ceiling insulation.

Conclusion

Considering all of the above, it can be noted that the answer to the question “What is better - laminated veneer lumber or logs?” depends on the source data. If finances allow, then you need to choose laminated laminated timber - with it the work will be easier, and the building will look more neat and modern. If you want to save money, then it is better to take a high-quality log.

In the video presented in this article you will find additional information on this topic.

Purchasing a ready-made log house from rounded logs or timber can significantly speed up, simplify and reduce the cost of building a house. It is important that it is assembled correctly and from high-quality material. After all, a log house is the basis of a building and, if its quality is poor, it significantly worsens living conditions. Therefore, before choosing a log house for your home, you should consider the following characteristics of logs:

- wood species,

- cutting season,

- thickness,

- type of cutting for laying.

Log quality

An indicator of good first-cut lumber is the absence of knots or their small number.

At the beginning of the article, we mentioned that in order to obtain financial benefits, trees are felled almost at the root, as a result of which a very thick layer has to be removed from one end of the log. As a result, we get soft ends without sapwood and, as a result, rotten corners of houses. It is quite easy to distinguish an incorrectly processed end by eye.

Be sure to pay attention to the set logs. They are easy to notice with the naked eye; their distinguishing marks are the following flaws:

Do not confuse them with knotholes; sometimes they are very similar. And, of course, you need to check the log house for the presence of bark beetle. This is especially true now; lately it has been difficult to find absolutely pure wood. Therefore, do not refuse the purchase just because of a few marks. Just inject a little turpentine into it through a syringe.