SNiP standards for the location of the furnace from the walls

The standards for these requirements are specified in 2 main documents:

- SNiP III-G.11-62;

- SNiP 2.04.05-91.

Based on these regulatory documents, each owner of a solid fuel stove is required to maintain minimum clearances from the wall and ceiling, taking into account the surface material:

| Parameter | Requirement |

| Installing the stove on a floor made of flammable materials. | The distance to the bottom of the stove must be at least 140 mm. |

| Foundation size. | When installing a steel stove on a wooden floor, the size of the foundation should be 1000 mm larger than the dimensions of the stove. |

| The ceiling is protected by asbestos slabs, plaster and sheet metal up to 1 cm thick. | In this case, the brick-lined stove is made in height so that the gap to the ceiling is at least 250 mm. |

| When installing a steel stove with a protective layer of thermal insulation. | The minimum distance to the floor slab is 700 mm. |

| Installation of a steel stove without a protection layer. | This size increases to 1000 mm. |

| Minimum dimensions for walls according to SNIP from 1962 | |

| Distance from stove to wood stove with unprotected surface. | From 1000 mm. |

| The walls are lined with brick and plastered with lime mortar with a layer of 25 mm. Or an asbestos heat insulator 4 cm thick is fixed. | 130 mm |

| The wooden walls are lined with brick, 120 mm thick and plastered with lime and asbestos. When installing protection on the walls in the form of a 40 mm asbestos-vermuculite slab. | 300 mm |

By maintaining the minimum dimensions, or better yet, making gaps with a small margin, every owner of a wooden house can be sure that its walls and ceiling are protected from high temperatures.

One of the main methods of protection is the manufacture of devices installed to protect the front and side surfaces near the stove itself.

Treatment of wood with fire-fighting compounds

Fire protection of a house involves treating its structures by applying special compounds to a wooden surface, or even impregnating logs or beams with them. During combustion or incandescence, the fire-resistant coating of wood begins to produce inert gases that protect the wood from fire, for example, by forming a layer of a special heat-insulating mixture.

Or preventing the access of oxygen to the site of fire. In addition to such fire-retardant impregnating compounds for structural elements protected from water, impregnation of open parts of engineering structures with a special paint and varnish composition is also used. There are also special non-flammable insulation materials for walls and ceilings that can help in case of fire.

In wooden houses, rafters, floor beams, places and structures in contact with fire hazardous elements (stove, electrical wiring, fireplace) are treated with a fire retardant compound. Then it is advisable to process all frame partitions and all interfloor ceilings. Voids in structures are stimulants for the spread of fire during a fire; they cause draft and “stretch” the fire, heating up the fire.

Protective screens near or around the oven

Such a system will need to be implemented when installing a potbelly stove in the corner of the room. You can mount or lay out several screens from brick, installed at a short distance from each other. In this case:

- The first screen protects a person from touching the iron stove and getting burned. It is usually made of refractory or fireclay bricks;

- To protect walls made of flammable material, a second layer of protection is provided. It can be made of brick or covered with a barrier made of sheet steel with a mirror-like front surface. In this case, heat waves will be reflected from the mirror and spread faster throughout the room;

- if the foundation is insufficient in size or it is impossible to manufacture it, it will be necessary to lay a protective screen made of durable fire-resistant material on the wooden floor. This can be a sheet of steel or a decorative layer of heat-resistant clinker tiles or porcelain stoneware. The surface will first have to be covered with a layer of thermal insulation.

Installation of metal screens

This is the easiest way to make surface protection. It is better to use sheets with a polished front surface. Before fastening, the wall surface at the required level along the height of the screen is covered with a layer of thermal insulation. In this way, we protect the surface of the walls from the effects of heat.

You can lay a layer of thermal insulation or fasten the metal with self-tapping screws with inserted ceramic spacers. But it is better to attach the screen to strips or a metal profile treated with a layer of protection. In this option, the air gap will not allow heat to pass freely to the walls, and reliable insulation of the stove from the wooden wall is ensured.

A special gap is made at the bottom of the wall for the passage of cold air, ventilation of the wall and screen. When arranging a wall with a layer of thermal insulation, a number of longitudinal guides are installed on the surface. The space between them is filled with a layer of mineral wool or other material. Then sheets of metal are installed and screwed to the sheathing with self-tapping screws.

In this design, there is no need to leave a gap at the bottom. The air will not be able to pass through calmly, but the wall will be reliably protected from high temperatures. To protect the floor of the house, a slab made of non-flammable durable material can be used.

Brick screens

This protection option is usually installed near the stove. Thus, you can protect not only the wall, but also the person from burns. By installing a brick wall, you can reduce the distance from the stove to the wall. For laying, it is better to use ceramic or fire-resistant bricks.

The work is carried out in several stages:

- you will need to make a small foundation or remove boards from the floor along the marking lines for laying the screen and, by drilling holes in the concrete of the base of the building, insert metal rods to fasten the bottom of the wall and the foundation;

- Having leveled the floor surface, lay out a layer of mortar and lay the first row of bricks; you need to place the bricks in the same plane without distortions. This determines how level your entire wall will be. Do not forget to make small grooves for ventilation; for this you can move several bricks of the bottom row.

- checking the level and pulling the twine for laying each subsequent row, all bricks are laid on a mortar of clay and sand. Having raised the wall to the required height, the top is sealed with a layer of mortar or covered with a board. This way you can make a shelf for decorative ornaments and all sorts of little things.

The brick is laid no higher than the top of the furnace at a distance of at least 40-100 mm from it.

Using both types of protective screens, you can reduce the distance from the oven to 500 mm.

Examples of installation of protective brick screens in the photo:

Types of materials

Refractory materials can be roughly divided according to the method of heat transfer:

- Heat reflective – aimed at reflecting infrared radiation into the room;

- Preventing loss due to its physical and chemical properties.

On video of fireproof materials for walls around furnaces:

But all of them can also differ in the type of raw materials from which they are produced:

- With organic components, for example, polystyrene foam materials, although their fire resistance is very low, they are best suited for walls near stoves with low heat;

- Inorganic is a broad class of non-combustible materials for insulating walls of a wide variety of fire resistance, including very flammable ones, such as wooden floors. These include stone and basalt wool, pressed into large slabs, fiberglass wool, lightweight cellular concrete slabs with fire retardant impregnations, honeycomb plastics, foamed perlite or vermiculite, and polypropylene. However, such a beautiful decorative thing as Leroy Merlin sheet plastic is definitely not suitable.

- Mixed type - these include asbestos-cement refractories, asbestos-lime or silica, foamed from a variety of inorganic substances.

Basic requirements for refractory materials

Many country buildings are built from wood, be it a cylindrical or frame house; without a stove or fireplace it is difficult to survive a frosty winter, so their arrangement is approached very carefully, and the materials placed around the stoves are chosen so that they are:

- Effectively and reliably prevented any attempted fires;

- Environmentally friendly, so that when heated they do not release harmful substances into the home air.

But what are the dimensions of a standard oven brick can be seen here.

You may also be interested in learning about what kind of brick is used for laying stoves.

For walls around stoves

A long time ago, people used asbestos sheets to line the walls around stoves, but it turned out to be very harmful to health and the environment - its microparticles can enter the lungs or be deposited on things, which leads to serious illnesses, and with strong heating they also release carcinogenic substances. substances. Therefore, the best materials can be considered:

Fire-resistant plasterboards. can act as the basis for covering walls around hot stoves, and for decoration, porcelain tiles of the most unusual colors can be used.

The sheets have the following characteristics:

- Fire resistance – up to 30 minutes of fire resistance;

- Does not ignite for up to 1 hour even after a fire has formed;

- Slab parameters – 120 x 250 x 1.25;

- On the front and back sides there is cardboard treated with gypsum, inside there are fiberglass threads that will resist fire;

- The ends of the sheets are covered with cardboard material, and there is a joining chamfer along them;

- Fastening can be done either using adhesives or self-tapping screws.

Fireproof minirite slabs. The material has excellent heat-resistant properties and is produced exclusively from environmentally friendly substances, including:

- Compositions of white or gray cement make up up to 90% of the total material;

- Included are mineral fibrous materials;

- For strength and durability, fiber reinforcing boards are used.

Asbestos fiber is completely excluded from the composition, which improves the quality of the material for a home stove. It is easy to mount it on the wall with screws close to the wall itself; for reliability, you can mount 2 sheets of minirite

Note! When installing, it is necessary to leave a small distance, since the material may increase in size when heated. For other walls, you can choose a similar decorative brick finish

Protective stainless steel sheets are a slightly expensive but reliable fireproof material that can be used to protect not only the walls of the house, but also the basement when installing a heating boiler. But in order to provide the greatest protection, special fiberglass with thermal protective properties should be placed under the stainless steel - the structure will reliably protect the house from any attempts to start a fire. Choose the substrate carefully so that it does not contain harmful phenolic resins; when heated strongly, they release substances that are too hazardous to health.

Installing a stove in a bathhouse with an external firebox: fire safety rules

Regardless of what type of stove is installed, there are a number of requirements that must be met. In particular, we are talking about ensuring that surfaces heated to high temperatures (up to several hundred degrees) do not come into contact with flammable materials.

The main source of danger in a bathhouse is the stove . Both the floor and the ceiling need to be protected from it. By the way, you don’t have to protect the walls if you place the stove at a sufficient distance from them.

And even if you are busy installing a stove in a bathhouse with an external firebox, the first thing you need to do is protect its base . It doesn’t matter whether you place it on a foundation or directly on a wooden floor - in any case, you need to lay a sheet of fire-resistant material (asbestos or basalt cardboard, for example) under the stove, on top of which you need to place a sheet of metal .

Foundation diagram for a massive furnace (see more about furnace foundations).

Asbestos cardboard for placing under a not very heavy stove (see more about installing stoves).

Another universal point of fire protection is the correct installation of the chimney through the ceiling and roof.

Ceiling passage box

The walls remain. Since in this case we are talking about installing a stove with a remote firebox, the main “problem” will be the passage of the fuel channel directly through the wall , and the distance between the wall and the stove will be minimal - about 5 cm on average. This means that covering the wall with fireproof materials alone will not do.

Related article: What sandpaper to use to clean putty on walls

Therefore, we will analyze two options: installing a stove in a bathhouse with an external firebox, when the walls are flammable (that is, wooden) and non-flammable (brick, block concrete). The material is also a criterion for dividing stoves into separate types; in accordance with this classification, metal and brick stoves are distinguished. Some experts classify cast iron stoves as a separate category. In addition, there are other types of stoves:

Where to install the stove

You can’t just put a stove in the middle of the steam room; it’s important to take into account the location of the air ducts, correctly calculate the distances from the walls, and think about protecting the walls of the bathhouse from heat.

If you look at the “Appendix to SNiP 41-01-2003”, you will find lines where it is clearly stated that if the walls of the bathhouse are not flammable, that is, they have a fire resistance limit of 60 minutes or more, then a metal stove is allowed to be installed at any distance, but it is better when there is more than 380 mm of free space between the steel stove and the wall. If you look at the “Appendix to SNiP 41-01-2003”, you can find lines where it is clearly stated that if the walls of the bathhouse are not flammable, then there is a fire resistance limit 60 minutes or more, then a metal stove is allowed to be installed at any distance, but it is better when there is more than 380 mm of free space between the steel stove and the wall.

It is quite difficult to find completely brick or concrete walls in a bathhouse without cladding; often the finishing is done with highly flammable wooden paneling.

It’s another matter if the wall material is wood. In this case, you should adhere to the following rules:

- When purchasing a factory stove, ask for instructions for it and carry out the installation strictly according to the manufacturer’s diagrams. This rule is stated in SNiP 41-01-2010, namely in paragraph 6.6.2.19 (Individual stove heating);

- there should be more than half a meter from the hot walls of the unit to the walls not protected by screens;

- the wall or partition through which the fuel channel is discharged must be made of non-combustible material from the floor itself to a mark of 25 centimeters above the combustion door;

- the thickness of the non-combustible wall through which the fuel channel is routed must be 12.5 cm;

- if the ceiling in the steam room is thermally insulated and protected with plaster over a metal mesh or similar, then the distance from the top of the metal stove to the ceiling should be more than 80 cm;

- in cases where the ceiling is not protected by fireproof materials, the distance from it to the stove should be more than 1.2 m;

- from the fire door to the opposite wall there should be more than 125 centimeters;

- Leave 3 cm between the wall and the front wall of the stove with an external firebox.

Fireproof distances from the stove to the walls

When choosing the best location for your own furnace, take into account the location of such elements as external heat exchangers, wall-mounted heaters, hot water tanks, and pipelines for remote tanks. These elements must be freely accessible for repair and maintenance.

Installation of a sauna stove with a remote firebox in a sauna made of non-combustible material

The simplest situation is when you do not have to replace part of the wall . However, if the walls of the steam room are sheathed with wood, you will have to remove this sheathing on part of the wall. The base - stone or concrete - is not a combustible material, so the hole that will be made in it depends solely on the parameters of the outlet channel of a particular furnace.

The expansion of metal when heated is the reason to make the opening a centimeter or two wider than the dimensions of the channel itself. The empty space between it and the wall is filled with refractory, and not only basalt wool, but also asbestos cord will do.

We have already mentioned the finishing of non-combustible walls with wood (lining, false beams, etc.). The minimum distance to which it should be removed is 25 cm . But do half a meter and you won’t go wrong. And in height - 25 cm above the edge of the stove.

In the photo, the gang is standing with one edge on a shelf, holding the stove with its handle, and the distance to unprotected flammable materials should be at least half a meter. What is behind the stove is a sheet of metal, possibly on top of the refractory, but you need to leave a gap between the wall and the refractory (ceramic bushings for this). The size of this sheet is a little small - if we take the diameter of the chimney as 12 cm, then the sheet extends beyond the stove up and to the side by no more than 20 cm. Another five would be nice). In general, the design is “on the brink”. Note also that without passing through the wall, the insulation can really be just that - a sheet of refractory. sheet metal and that's it.

The edges of the lining are covered with platband . The bare wall inside the steam room can be decorated with tiles , the type that can withstand high temperatures, or with natural stone - do not forget that the stove is very close to the wall. Plaster is also good. A portal is usually made in an adjacent room.

Purpose and functions of the chimney

Before we start learning how to build a passage through the ceiling for a chimney, it wouldn’t hurt to get to know the main “hero” for whom, in fact, this work is being carried out. So, you already understand that the chimney is important and necessary. Why? How does it function? Thanks to this miracle pipe, clean air, separated from gases, enters the firebox.

Where do the harmful compounds that appear as a result of burning wood go? They go through the pipe into the sky. Moreover, without any motors, levers, current or intervention of human hands, but in a simple way - under the influence of traction of natural origin. Here is a magical device that seems extremely simple, but to achieve this natural simplicity, you will have to work hard. Ready?

A chimney in a bathhouse is like an engine in a car, one of the important components

Immutable rules

What are the requirements for the chimney and its passage through the ceiling of the bathhouse?

So, remember this important list:

- the most suitable pipe length is 5 meters;

- the prefabricated structure should not contain protrusions (the main guideline is the vertical position);

- the optimal height above the roof level is up to 1.5 meters (otherwise stretch marks will be required);

- the distance between the pipe and the ceilings must be at least 13 cm with cutting the passage and 30 cm without it;

- Smoke elements cannot be joined in roof or ceiling structures;

- contact of the pipe with communications (plumbing, ventilation, wiring, sewerage) is unacceptable.

This is how the bathhouse heating system works

Work plan

Now that you are familiar with the design and the basic requirements for it, you can learn how to construct a chimney passage through the ceiling. Learn a step-by-step case study:

- Surface cutting and marking.

- Box installation.

- Sheet installation.

- Arrangement (insulation) of the opening.

This, as you understand, is a theory that needs to be put into practice, and that’s what we’ll do.

This is what the installed chimney looks like from the attic side

Installation of a sauna stove with a remote firebox in a steam room made of flammable material

The size of the hole that will have to be cut in the wall made of wood is significantly larger than the previous one. We are talking about an opening within which a small brick wall will be built. It is she who will be in contact with the furnace channel .

The minimum opening dimensions when installing a sauna stove with an external firebox are calculated as follows:

- It is better to calculate the height, as before, from the top edge of the stove, adding a minimum of 25 cm to it;

- the width consists of the width of the fuel channel, expansion gaps (1-2 cm on both sides) and a minimum of 25 cm under the brickwork. Plus a small gap between the brick and the wooden wall.

Between the channel and the brick , as well as between the brick and the wood of the wall, a refractory must be laid - basalt wool, asbestos cord, and you need to pay attention to the temperature characteristics of the refractory that is in contact with the stove - firewood burns at temperatures up to 1000 degrees, the insulator must withstand these temperatures, Therefore, glass wool is definitely not suitable.

Angular position of a stove with a remote firebox for a bath

Above we talked about the option when the installation of a sauna stove with a remote firebox is not carried out in one of the corners of the steam room. That is, there is contact with only one wall. But it also happens that it is more convenient for the owner to place the stove in the very corner. And if the walls are made of wood, then you will have to protect not one, but two.

The distance to the adjacent wall can be reduced to 25 cm if a refractory sheet is hung on it.

In another article we talked about single and double mineralite sheets. So, a double one with an air gap allows you to place the stove at a distance of 12 cm from the wall.

Finishing of a plastered stove

If you want to create a noble finish, then after the last layer of plaster applied to the surface of the stove has completely dried, you need to begin applying the final finish. It can be a regular whitewash, but if you want to create a special pattern or add depth to the color, you should use decorative plaster as the final layer. The finishing of a plastered stove involves:

- Application of fire-resistant paint to create a coating suitable for the chosen style and interior;

- Performing hand painting;

- The use of decorative elements in decoration.

Plaster with decorative elements

If the option of whitewashing the surface is chosen, then chalk is used for this, to which salt and blue are added. The composition adheres securely to the surface and does not crumble. Salt can also be added to regular plaster - this will give the material additional strength.

The use of heat-resistant paints will make the surface of the stove individual and bright. This material is waterproof, so the masonry can be washed - the quality will not suffer. The following types of heat-resistant paints are distinguished:

- Alkyd;

- Silicon-organic;

- Organo-silicate.

Each option has certain advantages and a wide range of shades. If you are finishing a stove in the kitchen, it is recommended to use liquid glass as a finishing coating. Additionally, you can apply an unusual decor to it - an ink drawing.

Decorative plaster

Decorative plaster is a material that contains special substances that make it possible to create an imitation of various textures on the surface:

- Wood;

- Brick;

- Marble;

- Stone.

The main components of decorative plaster are cement and various fillers of mineral origin.

An option for finishing a plastered stove is to apply the desired pattern to a layer of wet (not completely dry) plaster - most often these are geometric patterns, called rustication by professional decorators. After application, they can be painted immediately. A modern option for decorative finishing is the application of glass wallpaper. They are fire-resistant and do not emit harmful substances in case of strong heating. The main materials from which this coating is made:

- Glass;

- Dolomite.

Additionally the following components are included. How:

- Quartz sand;

- Soda.

Fiberglass wallpapers are highly durable and can also be painted.

Protecting a wooden wall from the heat of a stove

Wooden baths require especially careful compliance with fire safety rules when arranging them. The source of the fire can be anything, an unextinguished cigarette, coals falling from the furnace of the firebox, an uncleaned chimney, but the main source of threat remains the stove itself.

The surface of the stove heats up to 300° - 400°, the heat falls on the wooden walls, which leads to their excessive heating and charring. It is extremely difficult to stop the process of ignition of wooden surfaces; the best way to avoid a fire is to prevent it. There are two truly effective ways to insulate the surface of wooden walls from the heat of sauna stoves - protective equipment in the form of a screen or the construction of special cladding from non-combustible materials.

Fireproof mineralite slabs

This material is characterized by high heat resistance and is made only from environmentally friendly substances:

- white/gray cement - up to 90% of the total material;

- mineral fibrous materials;

- Fibers reinforcing the slabs - give the slabs durability and strength.

The composition does not contain asbestos fibers, making these fire-resistant high-temperature boards suitable for home ovens. The slabs are quickly mounted on the wall using screws to the wall itself. To ensure higher reliability of the structure, you can install two sheets of minirite.

When installing, you need to leave a small distance, because When heated, the material may expand slightly.

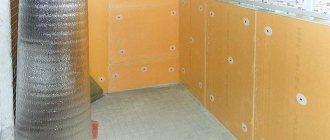

Wall finishing with fire-resistant mineralite slabs

When is this required?

There are times when there is no need to protect walls. If the stove is located at a safe distance from the wall from a fire safety point of view, the installation of protective screens and other measures can be neglected. The distance from the walls that is required to reduce the heat from the source varies:

- A stove laid in a quarter of a brick should be located no closer than 35-40 cm from the wall;

- A metal stove without lining should be placed a meter away and no closer;

- A metal one with a lined furnace can be installed 70-75cm from the wall.

However, not every steam room has the opportunity to fulfill these requirements, due to the small area. The layout of steam rooms with an area of 6-8 m² can hardly accommodate the necessary set of items for the steaming procedure. Therefore, the need to insulate walls with special sheathing is relevant.

Fire automatics

Installing a fire safety system is your choice; it is not a mandatory element for everyone. This is a desirable system. But if you decide to install such a fire protection system, then this should be done in accordance with all the requirements of the relevant standards and SNiP. Only this will ensure their maximum effectiveness. Half solutions are ineffective.

Numerous practical cases indicate that a timely signal about the start of a fire will prevent a more destructive fire. The damage from such a fire is not comparable to the resources, both monetary and mental, sufficient to install a fire safety system. If you “save money” on this, then the most disastrous results are possible.

It must be taken into account that, for example, by installing the simplest and most inexpensive smoke detector in distribution cabinets of electrical networks, you can prevent the fire itself and reduce the likelihood of a fire. In any home, according to statistics, the main source of household fires is electrical wiring. It should be well arranged, well insulated.

In a country house, you can also install a fire sensor in technical fire-hazardous rooms. This is a boiler room, a garage, a flight of stairs, a cold storage room and other rooms. If an electronic fire alarm system is installed, then for its effectiveness it is necessary to have reliable (serviceable, in working order) primary fire extinguishing equipment (fire extinguishers, a shovel, a hook, a box of sand). This is provided for by the basics of fire safety and will not require any great effort.

it has a low price (compared to other types of fire extinguishers), it is easy to maintain, and it is environmentally friendly. Most of these modules can operate in electric auto-start mode (based on a fire sensor signal) or in self-start mode (if the temperature rises to a critical value, the value of which was initially set in the system). Such modules have a place in fire-hazardous technical rooms (boiler room, garage, etc.).

The powder module, complete with electronic control, stands out as a separate automatic fire extinguishing system. It can also act as an integral part of a fire security system if its output is combined with the input of an automatic fire extinguishing system. Recently, the concept of “smart home” has been used.

Application of protective screens

Screens are shields made of brick or metal that protect walls from intense thermal radiation. Similar protection is used when installing metal stoves.

- Metal screens are made from steel or cast iron sheets, these

casings surround the heat source with a distance of 3-5cm.

Advice! When purchasing a metal sauna stove, you should give preference to a model equipped with a metal casing. Its cost is not much higher, but the issues of wall insulation are eliminated.

Additional frontal or front shielding, which is located on the walls depending on the location of the stove, will not hurt. The protection guarantees the wood from overheating, reducing the temperature by 100 degrees or more, and provides the opportunity to save space in the steam room. A stove protected by a casing can be installed at a distance of 50-55cm from the wall.

Installation of screens is simple. The casing, equipped with legs, is secured to the floor by side or front screens - with galvanized nails or self-tapping screws.

- Brick screens are masonry used to cover the stove with

on all sides, the same casing, only made of brick. Another method is to lay half a brick between the firebox and a wall made of solid fireclay bricks laid on a solution of clay and cement. The width of the wall should be 120mm, although there is an opinion that it is permissible to put 60mm in a quarter of a brick, but it should be remembered that in this case the thermal insulation value is reduced by exactly half. It is recommended to raise the height of the masonry 20-30 cm above the surface of the firebox, but if you raise it to the ceiling, it will not be worse.

Related article: Wall-mounted spice rack

The screen should be placed at a distance of 10-15cm from the wall, 5-15cm from the stove, that is, the space saving is 30-40cm

Important! Functional openings for heat exchange should be made at the bottom of the masonry.

Protective screens are effective; they reduce the temperature to a level acceptable when using high-temperature fuel units. The same function is performed by wall cladding made of non-combustible materials.

how to decorate a heated wall in a house

November 11 at 16:25

I already wrote, yes it is possible, following technology. Clean to clay, if necessary, repair the surface with a clay solution 1:4, after drying, prime 3 times with a deep penetration solution, glue with a special glue for warm walls, if painted, use water-based latex. Due to their characteristics, glass wallpaper also plays a reinforcing role, which will help strengthen the wall. Their air exchange rates are high, therefore heat from the walls will not be retained through them. They also do not deform under the influence of temperatures and moisture. Durability 20-30 years, can be painted up to 20 times.

In general, here, first of all, you need to deal with the reason. that is, it turns out that your wall absorbs moisture, and at the beginning of the heating season it dries out and cracks. Plus, shrinkage, the house is already old. Well, you should also veneer the walls and foundation from the outside (but you already know that), and if everything is already done on the outside, sew on the inside walls, again, a reflector and drywall on the frame. At this point, you can add additional insulation by putting thermal insulation into the frame. And also, you need to think about ventilation. Such an old house made of adobe can develop a major crack at any moment from sudden wetting and drying.

November 12 at 10:10

Why don't you like drywall? There are fireproof sheets that can be attached to a warm or hot surface. And stick photo wallpaper on the top of the sheet. The main thing is that the surface is well primed. Preferably a deep-acting primer. It will be better to keep it that way.

Covering bathhouse walls with non-combustible insulating materials

To prevent the walls from overheating, you can use materials with increased thermal insulation properties and inertness to high temperatures. Two types of materials are used:

- reflective;

- fireproof with lining.

The first type includes materials for wall cladding, consisting of thermal insulation with fire-resistant properties and a metal covering in the form of a sheet.

Insulating walls with reflective sheathing

A protective cake with reflective materials is done this way. First, the thermal insulation is attached using ceramic bushings directly to the wooden walls, then it is sewn up with a stainless steel sheet.

Advice! It is better not to use galvanized metal, since heating may release heavy metals harmful to the human body.

Stainless steel with a polished surface reflects the heat flow inside the steam room, reducing heat loss. In this case, reflected heat is more useful than direct heat. For thermal insulation use:

- basalt cardboard or cotton wool, the only material with increased hygroscopicity, non-flammable, environmentally friendly;

- asbestos cardboard, which reliably protects against flames and has a long service life;

- mineralite, an artificial material made specifically for these purposes.

Protective sheathing requires ventilation gaps of 2 cm from the wall to the insulation, 2 cm from the insulation to the steel sheet. If it is necessary to install the stove as close to the wall as possible, make a double skin of non-combustible insulation, use ceramic bushings to maintain gaps of 2-3 cm and sew them up with a steel sheet.

Insulation with cladding

Measures to protect walls with cladding are necessary in order to preserve the interior decoration of the room. They are more expensive, but no one has canceled the aesthetic advantages of the bathhouse. It is based on tile cladding, which is laid on fire-resistant cladding made of gypsum plasterboard, non-deformable gypsum-based cardboard with fiberglass, mineralite, non-flammable cement-fiber material, moisture-resistant and resistant to biochemical influences, LSU, fiberglass material bound with magnesium additives, resistant to high temperatures, high humidity. Heat-resistant glue is used for installation.

Advice! Use heat-resistant reinforced Terracotta glue, made from fireclay dust bound with kaolin additives, intended for tiling stoves, fireplaces, and all heated surfaces.

The recommended facing materials are quite varied, the best of them are:

- terracotta tiles, they are made from specially fired clay, which gives increased heat resistance and durability;

- clinker, denser clay tiles with a surface of various colors, similar to facing bricks;

- tiles, also made from clay, having an original embossed surface;

- porcelain stoneware made from a mixture of clays, kaolins, quartz sand, feldspars by high-temperature firing under a pressure of 400-500 kg/cm², with imitation of stone, wood, durable artificial material;

- soap chloride, a rock mineral consisting of talc, magnesite and chlorite, an environmentally friendly natural material that does not absorb moisture at all, has an attractive appearance, does not crumble, and is not afraid of high temperatures.

Advice! Use soap chloride to finish the steam room, this mineral has a healing effect on the human body, regulates blood pressure, stimulates cerebral circulation, expels viruses and microbes due to the release of vitamin D when heated.

All of the listed tiles are an element of protection that forms a cake, the basis of which is a fire-resistant material. Just like a screen, sheet material is installed on ceramic bushings with a gap of 2-3 cm from the wall. The minimum distance to the heat source from the tile should be 20cm.

Protection with cladding decorates the room, creates a positive mood, and helps to increase the efficiency of procedures. And most importantly, properly installed insulation prevents wooden walls from overheating and catching fire. Have a nice steam!

Types and rules for the manufacture of fireproof cladding

Fire walls can be created using sheathing made from non-combustible materials. Today, 2 variants of such designs are used:

- reflective coverings;

- sheathing with cladding.

To produce reflective protection, thermal insulation material is attached to the wooden surface of the walls, which is covered with a steel sheet. A few years ago, galvanized and stainless steel sheets were used equally widely. However, studies have shown that when heated, galvanized steel can release harmful substances, so it is preferable to build fire walls from stainless steel.

In order for the reflective effect to be as intense as possible, the surface of the sheet must be well polished (almost to a mirror finish).

Protective screen reflector made of stainless steel

The following can be used as a heat insulator fixed under steel:

- basalt wool, which has good thermal insulation characteristics and absolute environmental safety;

- basalt cardboard, the base of which includes basalt fiber;

- asbestos cardboard, characterized by good fire-resistant qualities;

- mineralite, made specifically for shielding surfaces.

Fire walls sheathed with steel sheets are quite simple to install. The main thing is to remember what each layer of cladding should consist of:

- wall;

- a gap of 2-3 cm, providing ventilation between the wooden surface and the heat insulator;

- thermal insulation material (at least 1-2 cm thick);

- sheet of steel.

The distance from the furnace body to the steel sheet must be at least 38 cm. It is recommended to use ceramic bushings for fastening materials. They are not exposed to heat and do not deform, ensuring the safety of the ventilation gap between the heat insulator and the wood.

Construction of a fire-resistant wall

When the distance between the heater and the wall is less than 38 cm, it is necessary to use a double layer of fire-resistant material. The best choice would be mineralite. It is secured with ceramic bushings with a gap of 2-3 cm from the wooden wall and covered with stainless steel.

How to insulate a wooden wall from a steel stove?

Table of contents

Installing a stove is a complex process and requires a lot of attention to each stage, from preparing the installation site to the nuances of removing the chimney pipe from the roof. In this article we will talk about how to properly insulate a wooden wall from a steel or cast iron stove. Any wood has a predisposition to ignition, so a constantly hot stove design can easily cause a fire. Any builder understands that insulating the wooden wall behind the stove is a mandatory process. Let's look at an example of installing a Bavaria stove-fireplace on a wooden floor next to a wooden wall. The furnace does not have a separate foundation, so a light base for a metal structure is required. The base for the stove will be laid out with bricks in one layer. In this case, wall insulation can be done in two versions: asbestos cement sheets or flame sheets (non-hot composition). There are several opinions about asbestos - sometimes they say that they emit toxic fumes. But flamm has its drawbacks: they have standard sheet sizes of 600x1200 mm, which can be inconvenient when working, and also in terms of price they do not beat asbestos cement at all.

Options for wall insulation

The width of a particular oven is 720 mm. As a result, it turns out that horizontal sheets need to be installed - you will need four sheets to the ceiling, it turns out that they can cover the upper part of the room - there is a beautiful partition there. There are several other options on how to proceed: get rid of the existing partition, replace it with a fireproof one and cover it with tiles or stone. You can also place a screen and use a circular saw to remove the wood on the partition completely. Next, finish with tiles, plaster or paint. There is no doubt that the tree needs to be removed. After all, if you cover it with non-flammable materials on top, there is still a chance that the wooden surface will ignite. In this case, it is better not to take risks and remove the partition from wood. Thermal radiation from the oven will not only be from the back wall. Lateral radiation will also emit radiation onto the wall at a distance of 0.8-1 meter. You should carefully read the installation instructions - the manufacturer describes everything very clearly there, including what concerns safety. For example, when a stove with a glass door is on and there is a chair next to it, it is better to move it further away (more than 1 meter).

Initially, the base for the stove was supposed to be one brick thick, but such a thickness for a wooden floor is not very good. Regarding the non-combustible partition, you should also note the importance of the situation - where the chimney will go, at what distance from the beams, walls and rafters. In the area of this Bavaria stove, it is best to use a concrete slab as a base - lay it along the beams, flush with the floors or a little more - it will turn out like a podium, reliable and ensuring safety. However, the bottom of this stove practically does not warm up; there is an additional part for firewood, which takes on the heat. Therefore, you can make it simpler - lay mineralite or CSP on the floor, then tiles or porcelain tiles on mastic or hot melt adhesive. In places where the chimney pipe is laid, you can use basalt, non-flammable or kaolin wool. Cotton wool plays the role of additional insulation and is placed in the ceiling section. In this case, you should make an opening in the ceiling - in accordance with safety standards - from the contour of the two-layer pipe - sandwich, 250 mm in different directions. The furnace cutting should be made of non-combustible materials - superisol, mineralite, calcium silicate, vermiculite. When passing through a chimney pipe, the groove should be filled with cotton wool.

Related article: How to decorate a wall directly with wallpaper

It is, of course, very difficult to get rid of a beautiful partition, because it was built for aesthetics, a lot of time was spent on it, but if it was decided to install a metal stove against this wall, then you should get rid of the additional threat of fire of wooden parts.

Wall insulation material

Facing materials are often made from cement, the complete hardening of which can take several years. As a result, even after the work has been completed, changes in size, bends and deflections may be observed. Some manufacturing companies (for example,), use an effective and efficient method of keeping facing materials in an autoclave in a high-temperature, high-pressure oven. And it turns out that shrinkage due to drying and expansion by exposure to heat can be avoided, and reliable strength is also ensured.

Those same Nitikha panels are made from fiber cement, a universal material that consists of 90% cement and 10% cellulose fibers and various mineral fillers. In this case, technology without the use of asbestos is used by pressing the ingredients.

Panels of this type are environmentally friendly; their production does not use formaldehyde resins, chlorine compounds or asbestos. Fiber cement has excellent fire-resistant properties; it fully fits into the category of non-combustible materials. Fiber cement siding has many advantages, including the fact that it can easily be used to select various design variations, and it is also easy to install. Instead of mineralite, you can also use glass magnetic sheets - this is a more budget option.

Characteristics and composition

Before talking about the characteristics of the product, we should understand what we are dealing with, namely, talk about the composition. It may change from manufacturer to manufacturer, but the essence remains the same. The main component of mineralite is cement.

It is at least 70% here. The rest is taken up by cellulose, as well as special additives. Despite the appearance and overall strength of the product, mineralite does not contain asbestos. This means that when heated, not a single gram of harmful substances is released, and destruction is also excluded.

Asbestos is known to even explode at critical temperatures. All products must include hydrobisifiers. These are special elements that protect the structure from moisture absorption, which prevents cracking in frosts, possible rotting and other types of damage.

Now, it's time to move on to the characteristics. Let's list the most important of them:

- High strength. This applies not only to exposure to shocks and external damage, but also to the effect of moisture on the surface when it is heated to a high degree, for example, in a bathhouse, as well as resistance to temperature changes and air humidity levels. The surface and structure as a whole are resistant to humidity levels, which expands the scope of use even to outdoor use.

- Does not burn. Manufacturers of mineralite indicate the class “NG”, which indicates the complete non-flammability of the product. This makes its scope wide and not limited only to saunas and baths.

- Invariance under various influencing factors. As previously mentioned, water repellents prevent moisture from getting inside. As for low/high temperatures, in the range from -100 to + 180, the structure does not react in any way, including the properties of linear expansion remain unchanged. The product is also resistant to chemically active environments, which is why mineralite is often used in the finishing of industrial premises.

- Stronger every day. We said that 70 percent of the material is cement. Thus, the more time passes from the date of production, the stronger the product becomes. And this continues for at least 50-70 years, after which the cement will lose its properties with the same uniformity.

- Environmentally friendly. Judge for yourself: cement, sand, cellulose and other mineral additives cannot harm humans and others. Thus, it is completely safe under any conditions.

As you can see, there are many characteristics that will become important and fundamental when choosing. But we must not forget about the fragility of products

The material is very fragile, so it must be transported, stored and stored with extreme care.

The same applies to processing. It cuts softly, you can use a hand or power tool, but to achieve the best result it is best to use cutting elements with a fine tooth.

Manufacturers and prices

- Basalt fiber panels cost 1 sq. meter - from 390 to 690 rubles. depending on the decor of the front side, produced by ESCAPLAT; On a photo panel made of basalt fiber

- Rolled fire-resistant non-woven material - cost of 1 linear meter from 112 rubles, produced by OgneuporEnergoHolding, LLC, Moscow; Photo Roll Fireproof Nonwoven Fabric

- Non-flammable composition for plastering walls with a volume of 20 liters at a price of 410 rubles per bucket, produced by a company from Perm.

Cladding with cladding

This option is practically no different from the previous one, however, if you don’t know how to decorate the wall behind the stove in the steam room in such a way as to preserve the beauty of the room while creating safe conditions, then this option is undoubtedly for you. Protect the walls using heat-resistant decorative materials laid on thermal insulation.

The finishing around the stove in the bathhouse can be done with the following materials:

- Clinker tiles are made from baked clay. It is characterized by high strength, heat resistance and durability. One of the advantages of this option is also the rich color palette, which includes not only black and white tones, but also blue or green colors;

- Terracotta tiles are also made from clay, but they are inferior to the previous option in terms of density and the number of possible colors;

- Soapstone is a good cladding option for a bathhouse, made from rocks of green and grayish shades. Has good heat resistance and strength;

- Tiles are ordinary ceramic tiles, characterized by good heat resistance and a pattern on their surface;

- Porcelain tiles are heat-resistant tiles that imitate natural stone or wood.

The tile will not dissipate heat, protecting the walls from fire, so it cannot be mounted directly on the wall. We recommend using the following design:

- Wall;

- Clearance for ventilation;

- Fireproof material;

- Tiles (the distance from the tile to the stove must be at least 15 cm).

Such a “pie” will create reliable protection for walls from heat, preserving the beauty of the room.

One of the following options can be used as a fireproof material:

- Fireproof drywall - made from the same materials as regular drywall, but using fiberglass;

- Minerite slabs for baths are absolutely not exposed to moisture and heat.

- Glass-magnesium sheet - plates made of fiberglass and magnesium binder. Excellent resistance to heat, moisture and noise.

This option will perfectly protect your bathhouse from the possibility of fire, and will also insulate the room, preserving its aesthetic component.

Wooden houses: insure, be sure to insure...

• electrical wiring is made of double-insulated wire; • fireplaces, stoves with cracks, faulty doors and drafts are not used; • floors, walls and partitions have the necessary fire insulation; • there are electrical supply projects approved (by the relevant authorities with approvals and permits) , heating, all necessary permits.

Traditionally, insurers insure a wooden house against risks: explosion, lightning, fire, flood, natural disaster, theft (burglary), robbery, robbery, falling trees (poles), collision with a vehicle. A full package of such insurance for a wooden house will cost approximately half a percent of the market value of the house. Please take into account that the possible damage from a fire will not be much less.