The quality of bath procedures depends on the comfortable temperature in the bathhouse. When building a bathhouse, many do not think about heating the dressing room, but in vain. The need to change clothes in an icy room has nothing to do with a contrast shower, swimming in an ice hole or wiping off with snow. In summer, the problem is not so noticeable, but in winter, the issue of a cold dressing room becomes relevant, especially if there are small children in the family.

Rules for organizing heating in a bathhouse

Wood heating of a bathhouse

The simplest option is a bathhouse with heating from home. This scheme involves connecting the steam room, dressing room and other premises to the autonomous heat supply of the cottage. But this can only be realized if the bathhouse structure is closely adjacent to the house or is located at a distance of no more than 3-4 m from it.

The most common option for the location of a building on a site is remote from a residential building. How to make water heating in a bathhouse and at the same time optimize the costs of its organization? Options for using standard schemes are possible, but at the same time the specifics of using the bathhouse should be taken into account:

- The source of thermal energy (boiler) must ensure heating of the air in the steam room to a level of +90°C +100°C. For this purpose, special sauna stoves with a container for stones are used;

- For rooms larger than 60 m², it is recommended to install pipe heating. Together with it, you can make a hot water system to increase comfort. If there is a second floor, heating of the attic of the bathhouse must be provided;

- Ensuring the removal of carbon monoxide along with a well-thought-out ventilation system;

- Fire safety. Since wood is used in the vast majority of cases for finishing rooms, its contact with heating elements - pipes, radiators - should be prevented.

Gas heating baths

Another important point is the choice of energy carrier. Gas heating in a bathhouse is advisable only when installing a specialized boiler. Installing homemade structures can lead to emergency and dangerous situations.

In addition to gas, you can use other, no less effective sources of thermal energy:

- Firewood. A traditional type of fuel with which heating a bathhouse in winter turns into a kind of ritual. A significant drawback is the constant monitoring of the fuel level in the firebox, as well as the impossibility of quickly adjusting the water heating level;

- Diesel fuel or used oil. The most unacceptable energy source for a bathhouse. The problem is the unpleasant smell and the difficulty in organizing fuel storage.

How to make gas heating for a bathhouse yourself? To do this, you need to choose the right equipment and components for heat supply - pipes, radiators, as well as containers for indirect heating of hot water.

When heating a bathhouse from the heating system of the house, part of the pipeline located on the street must be insulated. To solve this problem, you can use special heat insulators or an electric heating wire.

Features of gasification of a bath

Russian government decree No. 509 of 2008 states that gasification of a bathhouse is allowed. The only condition is that its use for commercial purposes is prohibited.

If the boiler is equipped with an atmospheric burner, the inspector will check the ventilation device and draft

The project should include:

- the presence of a separate entrance (heat-resistant materials are used to make the door);

- availability of fire extinguishing and alarm systems;

- the equipment must be industrially produced and have a quality certificate;

- It is mandatory to have a ventilation system and a carbon monoxide detector.

Practice shows that the chance of obtaining permission to gasify a bathhouse increases if all work is carried out by specialists competently and efficiently. After the building of a bathhouse or sauna is built, it should be registered with the BTI. The next stage is a trip to the city gas supply office, where an application for gasification is written.

When the application is reviewed, an inspector will visit the gasification site. As a result of the inspection, changes may be required (installation of additional ventilation, alteration of the chimney). When permission is received, all that remains is to connect the equipment and insulate the bathhouse building.

After selecting and installing a gas boiler in the bathhouse, you can enjoy the result of your labor. Money and time costs are compensated by maximum comfort and safety. After all, modern equipment allows you to create an optimal balance between temperature and humidity, does not dry out the air and is ideal for lovers of a traditional bath.

Heating a bathhouse in winter with warm floors

Today, when heating the floor in a bathhouse, expanded clay, felt and other materials are often used. The insulation layer is placed between the joists or layers of building concrete. The width of the insulator should be within 15 centimeters. It is worth noting that thanks to the use of expanded clay insulation, you can additionally make a hood in the steam room.

To install electric heated floors in a bathhouse, a layer of heat-insulating material must be attached to a smooth and completely clean floor.

This is followed by the installation of a special steel mesh separating the liner from the coating. After this, the guide rails are installed, along which the electrical wire passes, and then the connection to the thermostat follows.

Here we talk in more detail about sauna stoves and indoor thermal insulation

Algorithm for constructing a metal furnace

The foundation for the stove should be made of non-combustible material. Fireclay brick, sheet metal or concrete are suitable. To make the base aesthetically pleasing, it can be tiled. The firebox door is directed to the opposite corner. The floors are made of fireproof material. If wood is used, it is covered with a metal sheet 60 cm wide.

To create a classic interior design in a bathhouse, a metal stove can be lined with brick. In addition to being beautiful, this move will prevent burns. To properly build a chimney and determine at what distance from the walls the heater should be placed, be sure to study the instructions.

Gas heating

The implementation of such a heating system has several options.

- Firstly, as I wrote above, it is possible to install a “classic” heater, in which a gas burner will be used instead of firewood.

- Secondly, you can use a standard gas boiler (the same as in residential buildings). But in this case, you will have to take care of the equipment of heating systems (installation of heating radiators, laying pipes, connecting a gas-carrying pipe to the bathhouse or a cylinder connection system).

- Thirdly, there is the possibility of installing heating from the house. In essence, this is the same option as the previous one, but with its own characteristics and disadvantages. A separate heating main is laid from the boiler used to heat the house to the bathhouse. This option is very convenient if your steam room is adjacent to the house or is very close to it.

If the distance to the bathhouse is relatively large, then in order to use this system in winter it is necessary to bury the heating main below the freezing level of the soil and insulate it well. This will prevent the possibility of defrosting and help reduce heat loss.

True, the undoubted advantage of this option is the complete elimination of the problem of maintaining a constant positive temperature in the bathhouse. In addition, you can do all the necessary work (if you have a certain skill) with your own hands.

Heating a bathhouse in winter

Many people believe that the bathhouse is one of the best places to lift your spirits and heal illnesses. When people come here, they want not only to have a good wash, but also to have a pleasant evening. That is why, when building a bathhouse, you should pay attention to all the details, because even the slightest flaw can negate the entire effect and cause a feeling of discomfort.

More attention should be paid to issues related to high-quality heating, because a cold bathhouse, in which icy air blows from all corners, is far from the most pleasant place

Cozy bath interior

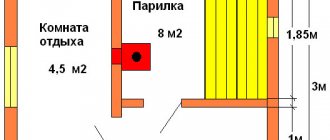

The bathhouse mainly includes two rooms: a dressing room and a steam room. The first is for resting and changing clothes, and the second is for washing. To build a bathhouse, you should use only high-quality materials; the reliability and durability of the future building depends on them.

How to save time on heating a bath

Probably every bathhouse owner had to mentally swear while heating the bathhouse on a frosty winter day. Indeed, sometimes, in order to raise the temperature in the steam room from -20 to 60... 80 degrees, you have to spend quite a lot of time and effort. And even when the air has warmed up to the desired temperature, the walls and shelves will remain cold for a long time.

Some people put up with the loss of extra hours, while others prefer to spend extra money when building a bathhouse, ordering the installation of convectors.

Today you can see both electric and gas convectors on sale. They have their pros and cons. The gas one is a little cheaper to operate, but the electric one is simple and will definitely not cause an explosion due to a fuel leak, which seriously frightens many potential owners.

Convectors do not need to operate at maximum power. On the contrary, even when operating in the most economical, “anti-freeze” mode, they easily maintain the temperature at 5... 10 degrees even on the coldest days. At the same time, the consumption of gas or electricity will be minimal, which means you won’t have to spend a lot of money on maintaining the convector. But every time you heat a bathhouse in winter, you will save a lot of time, which you can spend with greater benefit.

Heating with water and liquid fuel

Water heating is becoming more and more popular today. This is facilitated by the large selection of equipment that can be used. It should be remembered that this type of heating in a bathhouse should be arranged in such a way that during the warm season it can be turned off, leaving the heat exchanger to work only to heat the water. That is, you need to purchase a boiler with two circuits.

It is carried out using three types of fuel:

Gaza. To organize heating with gas, you must be connected to a common gas supply system. You will also need special equipment through which the fuel will flow. On the territory of our country there are a large number of settlements that are still not provided with gas. An alternative type of fuel – liquefied or bottled gas – has a higher fire hazard. Electricity

In order for electric heating to provide a comfortable room temperature, it is important to accurately select the power of the equipment. Due to the complexity of these calculations, it is not recommended to purchase and install an electric boiler yourself

Unlike gas heating, using electricity does not require the installation of a chimney. The disadvantage is the high cost of electric boilers, as well as the complexity of the technical process. Firewood. The wood-burning system allows you to warm up the room relatively quickly. In general, heating a steam room in a private house using wood-burning equipment is traditional. But many people do not like the complexity of the process of procuring fuel and lighting the stove.

Several alternative options

Despite the fact that the options described above are the most popular and considered optimal, I decided to briefly mention some alternatives. In fact, they are varieties of stove heating, but have their own characteristics.

For example, if you have such capabilities, then you can install a diesel fuel boiler in your bathhouse. But this option requires a separate room (diesel fuel does not smell much), and you need to think about fuel storage.

There are also pyrolysis heating boilers. The undoubted advantage of such a boiler can be considered a very long, almost complete combustion of fuel. The disadvantage is the high cost and difficulty of operation (for example, raw wood does not burn in it).

It is also possible to use long-term combustion boilers, capable of burning a separate batch of fuel for up to 5 days, maintaining the desired temperature. There are even options for high-quality graded coal. But this is rather an “industrial” option, which is not suitable for a good traditional bath.

An anecdote on the topic: Announcement on the doors of the housing office. Tomorrow at 12.00 for non-payment of utilities, electricity, heating, cold and hot water will be turned off in your home, windows and doors will be broken. Best regards, Administration.

This is where I will finish the review of methods for heating a bath. Which heating is better is up to you to decide, focusing on your needs and capabilities. The main thing is that the rooms are warm and comfortable. Thank you for reading to the end. Until next time, see you on the pages of other articles. Bye!

Wisdom Quote: There are no dark times, only dark people (Roland Romain).

The quality of bath procedures depends on the comfortable temperature in the bathhouse. When building a bathhouse, many do not think about heating the dressing room, but in vain. The need to change clothes in an icy room has nothing to do with a contrast shower, swimming in an ice hole or wiping off with snow. In summer, the problem is not so noticeable, but in winter, the issue of a cold dressing room becomes relevant, especially if there are small children in the family.

Choice

What are the characteristics of gas stoves intended for baths?

Stones

The traditional stove for a Russian bath - a heater - is distinguished by a large number of round stones placed in a tray. The tray is located above the firebox and, after lighting the stove, heats up quite quickly; the stones heat up to temperatures of 200 degrees or more.

They perform a dual function:

- By accumulating heat, the stones maintain a high temperature in the steam room after the wood burns out.

- The very name “steam room” implies the presence of steam. The traditional mode for a Russian bath is 60 degrees with very high humidity. To add steam, just splash water from a ladle onto the stones.

Gas heater Ermak.

If you are a fan of the Russian bathhouse, a heater is your obvious choice. If you want to use a sauna with high temperatures and minimal humidity, you don't need stones. Heat accumulation in the case of gas, you understand, is of no value.

Water tank location

It may be located in the stove body or around the chimney. In the first case, the heat source for heating water is the burner flame, in the second - combustion products. In the author’s humble opinion, the second option is preferable: the tank additionally cools the combustion products, increasing the efficiency of the device.

Gas stoves

If you use bottled gas, a stove that combines two types of fuel would be an excellent solution for you. When the cylinder runs out, you can light the stove with wood.

Burner

Often it is purchased separately.

What should you pay attention to when purchasing?

- With a steam room volume of 18 m3, the reasonable maximum gas consumption by the burner is 1.5 m3 per hour. It is easy to recalculate the required productivity for your volume.

- The registration certificate and markings must be present. Automatic shutdown when the flame goes out is mandatory (in fact, now it is available almost everywhere).

- Any damage, even seemingly uncritical, puts an end to the device. Big and fat. We are talking about people's lives and health.

Domestic burner Teplofor.

Bath heating system brief description, main advantages and disadvantages

Constant heating of the bath can be organized in several ways:

Connecting to centralized heating is not the cheapest, but the easiest option. Liquid or solid fuel boiler

The disadvantages are the same as those of a sauna stove: constant addition of fuel is required.

Using electricity is quite simple if it is possible to provide a separate, and what is important - guaranteed, 220/380V input (depending on the power of the heating boiler). But, firstly, you will need a whole package of documentation, which means money and time, and secondly, in rural areas there are often blackouts, and if your bathhouse is located in a summer cottage, then blackouts there may be the rule, not the exception

A power outage for several days in winter can cause the system to freeze. Heating using electricity also includes electric heated floors. The pleasure is not cheap, but comfortable. And you don’t have to cook batteries or registers; power outages do not have such fatal consequences: there is no water and nothing can go bad.

Gas boiler or convector. If your site has such a luxury as natural gas, then why not use it to heat your bathhouse? Of course, you need permits and a design, and gas boilers are not cheap, but the result is worth it. Use a pellet boiler. These systems are becoming increasingly popular. Firstly, due to the automated heating process. Pellets (from one bucket to several tons) are loaded into the bunker, and from there they are automatically fed into the boiler. You can check such a heating system once a month, or even less often: the fuel has a low ash content, and the bunker for storing it can be very large. Secondly, the installation of such a boiler does not require approvals, although the presence of electricity for ignition is required. But not everything is so rosy - pellet boilers have a high price.

If there is a heated house on the site, an option is to extend the heating main from the house to the bathhouse and heat it that way.

Advantages of wood stoves

Sauna stoves differ primarily in the type of heating. They are electric, gas, liquid fuel, wood-burning. Gas and liquid fuel ones are rarely installed in bathhouses, giving preference to electric and wood-burning ones.

Electric stoves have one huge advantage: they do not need a chimney, which greatly simplifies and reduces the cost of installation and reduces the fire hazard. But, if you compare the cost of electric “fuel” with the price of firewood, it will be significantly higher. And such a heater will not work from a regular network; it needs to be connected to a three-phase network, which is not possible everywhere.

Electric furnaces differ from each other only in power, installation method (floor-mounted or wall-mounted) and design; they are always installed in a steam room, which limits their use if the bathhouse does not have its own heating and water supply. They are selected according to these three criteria.

Electric heaters attract with their safety and original designSource r-sauna.ru

A much more difficult task is how to choose a stove for a wood-burning sauna, especially if it requires expanded functionality, and not just heating the steam room.

The main advantage of such equipment is its autonomy and lack of dependence on connection to electrical or gas networks. But there are others:

- Multifunctionality - a wood-burning stove can heat all rooms, heat water, and serve as a steam generator.

- It increases the temperature faster and heats up the stones more strongly, the heat of which determines the degree of steam formation and the “softness” of the steam.

- When wood burns, a special aroma is created - the sauna “spirit”.

- Firewood is cheaper than electricity.

Additional advantages include the traditional nature of bath procedures in a classic setting. True, this applies to a greater extent to brick stoves, but nothing prevents modern metal hearths from being covered with brick.

Construction of a brick screen around a metal stoveSource ytimg.com

Heating system

In most cases, continuous burning stoves are installed in bathhouses. which do an excellent job as the main source of heat in the room. At the same time, it is worth immediately making a reservation that for arranging the stove it is advisable to use only cleaned stones, the diameter of which reaches 10 centimeters. To achieve the optimal temperature in the room, it takes at least two hours to heat such a stove, during which you will have to periodically add firewood.

The bathhouse is a wooden building with a high level of humidity in the premises. As you know, wood that is regularly exposed to water can become unusable in a very short time. Because of this, unpleasant odors may appear in the bathhouse, and the building itself will require repairs in the future.

To avoid this, issues related to its quality heating should be resolved in advance. At the same time, it is advisable not to limit yourself to just one stove, but to supplement it with various heating systems, which, moreover, will significantly reduce the time it takes to warm up the premises before taking water procedures.

For safety reasons, in a wet room such as a bathhouse, it is allowed to use one or two heating radiators, which must be connected to the heating system of a residential building. In addition, there are several other options for heating a bath, the choice of which depends only on your requirements and wishes.

Heating radiators in the bathhouse

Electric heating

There are several options: you can install an electric boiler, since electricity is available almost everywhere. If we talk from a safety point of view, an electric boiler for heating a bathhouse is the safest option (subject to compliance with the rules and regulations). But the downside is that electricity costs a lot today, so you will have to pay large electricity bills. Another difficulty is that you will have to provide a separate input to connect the boiler, and often not 220V, but 380V is required, and these are completely different requirements and tariffs.

Electric boilers for water heating baths

If you use modern models of electric water heating units, then the bills may not be very large: they are controlled automatically, which maintains the set temperature in the room. You can set the temperature to +50C while you are not visiting the bathhouse. And the system will not freeze, and the bill will be small (provided that your building is well insulated). Moreover, to heat the bath, you can use stepped heating element boilers, induction and electrode (ion). They are not ideal, but according to experience, they are economical: bills come in 20-30% less.

Bath heating with convectors

If possible, it is most convenient to use electric convectors. Such a heating system in a bathhouse, of course, will be expensive. The equipment is not cheap, and electricity bills will also be hefty. But what is good about modern convectors: it is possible to set a certain thermal regime, which is maintained automatically. Many bathhouse owners do the following: while using the bathhouse, they heat the heater, and then set the anti-defrosting mode of the convector, which maintains the room temperature within +1 - +30C. Thus, the bathhouse premises do not freeze or become damp, and heating the bathhouse in winter will not cost a lot of money.

Heating in the bathhouse using convectors. Simple, but expensive and not always reliable

Electric heated floors

A very comfortable, but expensive type of heating. This applies to both the arrangement and the bills that will arrive. But if the bathhouse is insulated correctly and carefully, then maintaining the minimum temperature may not be so burdensome.

One more point: the system is installed at the stage of construction or major renovation, which is also not very convenient. Modern electric heated floors are no longer just cords that were laid out on the surface, and if damaged, part of the floor turned out to be unheated. There are roll materials with parallel thermal tracks. If one or more fail, the performance of the others remains unchanged, and the floor is still as warm.

Warm floors in the bathhouse can be made electric or water

Don't forget about safety

But it is not advisable to install electric heated floors in the steam room itself. Yes, this will make going to the bathhouse more comfortable. After all, true connoisseurs of baths know that it is the floors, especially in winter, that can remain cool even after heating for many hours. All the heat rises, and near the ceiling the temperature can reach 70-80 degrees, but the floors will remain cool. This definitely won’t happen when using electric heated floors - they will heat up much faster than the bathhouse will heat up.

But do not forget that in the steam room, liters of water are spilled on the floor every minute. But water and electricity are not compatible. Of course, the electrical cable is mounted in a concrete screed, on top of which boards are laid. Yes, the cable is supplied with all the necessary insulation, which guarantees maximum safety.

In this state of affairs, an unfortunate combination of circumstances is enough for you, your loved ones or guests to receive an electric shock. How can this end? The consequences can be the most tragic. Therefore, despite all the persuasion of experts, you should not install heated floors in the steam room, at least not electric ones.

Moreover, not all bathhouse visitors tolerate the heat equally well. And the bathhouse, in combination with the laws of physics, seems to specifically provide for such an option. People who love steam and heat can sit on the top shelf, and those who just went for company or have heart or blood pressure problems can sit on the shelf below - there they will feel more comfortable.

Gas heating

The implementation of such a heating system has several options.

- Firstly, as I wrote above, it is possible to install a “classic” heater, in which a gas burner will be used instead of firewood.

- Secondly, you can use a standard gas boiler (the same as in residential buildings). But in this case, you will have to take care of the equipment of heating systems (installation of heating radiators, laying pipes, connecting a gas-carrying pipe to the bathhouse or a cylinder connection system).

- Thirdly, there is the possibility of installing heating from the house. In essence, this is the same option as the previous one, but with its own characteristics and disadvantages. A separate heating main is laid from the boiler used to heat the house to the bathhouse. This option is very convenient if your steam room is adjacent to the house or is very close to it.

Gas heating baths

If the distance to the bathhouse is relatively large, then in order to use this system in winter it is necessary to bury the heating main below the freezing level of the soil and insulate it well. This will prevent the possibility of defrosting and help reduce heat loss.

True, the undoubted advantage of this option is the complete elimination of the problem of maintaining a constant positive temperature in the bathhouse. In addition, you can do all the necessary work (if you have a certain skill) with your own hands.

Water heating is rightfully considered one of the most convenient and effective methods of heating. In such a situation, there are also several options for manufacturing a system, which in any case will be powered from a furnace with a water circuit.

Fortunately, today in specialized stores you can easily select stoves that are ready for installation, equipped with a heat exchanger. This greatly simplifies the task of any builder of his own bathhouse. And now directly about the options.

Water heated floors

- External heating. It is done very simply and, in fact, is arranged in the same way as a brownie. Pipes located along the walls are connected to the furnace. Depending on the area of your bathhouse, a certain number of heating radiators are connected to the pipes. Hot water passing through them heats the structure and, when cooled, returns back to the boiler.

- Water heated floor. The principle of its operation is the same as in the first option. The only difference is that the pipes are hidden in the floor, which was previously insulated (I wrote about insulating floors in a bathhouse in more detail in other articles). This design is considered non-separable (although, of course, there would be a desire to break everything), and therefore requires a very careful approach to the procedure for its manufacture. In this case, I would recommend seeking help from specialists.

Furnaces with heat exchangers

Furnaces equipped with heat exchange devices allow you to successfully solve all the problems of heating a room, heating water, and creating steam. Heating a bathhouse from the heat exchanger of a bathhouse stove can include not only the main rooms of the bathhouse, but also auxiliary ones, for example, a shower room, a relaxation room, a swimming pool, a billiard room, etc.

- dimensions of the bathhouse and area of heated premises;

- dimensions and weight of the furnace;

- specific gravity of the heating device;

- the number of heat exchange devices included in the furnace kit;

- the total volume and composition of the circulating coolant;

- diameter and length of the chimney.

Sauna stoves with a heat exchanger can be connected using heat-insulated pipes:

- To a remote tank for heating water used in the washing section of the bathhouse.

- To heating radiators located in the service areas of the bathhouse - recreation room, billiard room, etc.

- To a hot water supply and water heating system, which includes not only the main and service areas of the bathhouse, but also the living areas of the house.

Stoves for heating baths with wood come with an internal or external heat exchanger. The internal heat exchanger is located in the combustion chamber between the body and the casing. It uses heat obtained directly from the combustion of fuel and heating of the furnace.

An external heat exchanger is installed around the chimney pipe. It uses the heat given off by heated gases when they are removed outside. Due to the increased volume of the external heat exchanger, its operating efficiency increases. Using the heat of the gases escaping through the chimney allows you to save fuel and increase the efficiency of the furnace by reducing the temperature of the exhaust gases.

In a cast iron stove, water is heated in a heat exchanger by exhaust flue gases and thermal radiation. The heat exchanger body is located in the upper part of the firebox in the area of the chimney.

A brick stove for a bath involves the location of a heat exchanger inside the brickwork in close proximity to the firebox. This somewhat increases the thermal inertia of the heat exchanger, and also reduces the likelihood of its overheating or oxidation of its surface under the influence of open fire.

Heater location

Usually the bathhouse is heated using one heat source. For a house next to which a unique bath complex is built (with a dressing room, steam room, swimming pool, relaxation room, room for playing billiards), a generally accepted heating system is required.

If heating is designed for a classic bath, then the stove is positioned so that it can be used to warm up each room. A tank of water is allocated a place near the washing room.

The ideal is a “through” arrangement of the furnace. The firebox door can be opened while in the dressing room. The stove itself will be located in the steam room, and the water tank will be located in the wash room.

It is important that each of the combustible elements of the furnace structure is protected from fire-resistant material. To comply with this, you can build a heater from brick, but it will have large dimensions and take up a lot of space.

A practical option is to build a stove, the design of which includes a tank and an open heater. The firebox for heating water is equipped with a register, which will prevent premature boiling of water, during which the unheated bath is filled with damp steam. Heating a bathhouse in this way requires observing an important nuance - the bottom edge of the tank should be 50 cm above the register.

Warm floor system

This option for heating a bathhouse is one of the modern methods, which has been used frequently in recent years. It is quite difficult to install special equipment without the appropriate experience.

It is much easier to install an electric floor system and you can do this work yourself:

- First of all, a waterproofing material is laid, on which a layer of mortar is placed.

- Next comes the installation of thermal insulation.

- An electrical cable is mounted on top of the thermal protection layer and the screed is refilled.

The technology for creating a floor with water heating is similar, but in this case they do not use a cable, but rather lay pipes to circulate the hot coolant.

If the bathhouse is multi-story

The appearance of private households has changed significantly over the past few centuries. The same applies to the bathhouse. Today it is not uncommon for baths to have, for example, two floors.

The presence of more than one floor requires the organization of heating of both the first and second floors. Existing systems are conventionally divided into a number of categories:

- integral or single heating;

- separate heating.

In the first case, it is assumed that the stove is installed directly in the steam room or behind its wall. The pipe through which the smoke will be exhausted is fixed to a special outlet on the equipment. It passes the perimeter of the first and second floors and only then leads out onto the roof.

It is important to remember that single heating requires that the stove be heated constantly, even if the steam room is not in use. In addition, the complex path of hot air circulation results in a long heating period for the room.

In this case, in the area where people steam, a standard set is installed - a stone, a vertical pipe and the stove itself. The remaining rooms are heated by gas, electricity and other sources.

In order for the heating of the steam room to give maximum effect, you must adhere to certain rules.

- First of all, this concerns firewood. They must be dry; the presence of even a small amount of moisture in them will slow down heating.

- The firewood must have the correct size: the diameter does not exceed 9 cm, but not less than 6 cm. Average values will allow the fuel to burn for a long time, give the required heat and, accordingly, temperature.

Experienced users claim that high-quality heating is also determined by the use of a certain type of raw material. If the question is how to make heating in a bathhouse with several floors, it is better to give preference to birch. This wood does not have a large diameter. However, the high tar content ensures long-term smoldering, due to which a high combustion temperature is achieved in comparison with other materials.

https://youtube.com/watch?v=Kj2xVG2VRbs

Additionally, to increase the time of maintaining high temperature, coal is used. Oak and linden also performed well when solving the problem of heating a bathhouse with several floors. Poplar and aspen emit less heat, so much more of them will be needed.

If the bathhouse is equipped with an attic, it is better to use a fireplace to heat it. When installing it, be sure to take into account the weight of the device, which requires mandatory strengthening of the area. The weight of the fireplace depends on how often you plan to use it. It is known that intensive heating requires a large firebox. To make installation and operation easier, it is better to give preference to an electric fireplace. This will also reduce the cost of estimated repair work.

Main components

In order to heat the dressing room efficiently, with minimal heat loss, you should take into account all the nuances of finishing the room. Without careful insulation, no heating device will have the desired effect. The choice of heating device must also be carefully thought out. A properly selected sauna stove can heat not only the steam room and dressing room, but also create comfortable conditions in the wash room or rest room, if any. If replacing the stove seems troublesome and expensive, or is impossible for some other reason, you can use additional devices and methods for heating the dressing room.

An example of a brick stove for heating a dressing room

Let's consider all the components of a warm dressing room in order.

Insulation of the room

In order for the heating of the dressing room to be effective, it is necessary to insulate the room in such a way as to avoid heat loss. When insulating, special attention should be paid to the floor and ceiling so that cold air from the ground and attic space cannot penetrate inside.

The material most often used to build a bathhouse is a log. If its diameter is large enough and the joints are well caulked, additional insulation of the walls may not be required. If the dressing room is made of thin timber or made in the form of a wooden frame bath, then the walls will need insulation. The principle of finishing the main planes is almost the same. First, a vapor barrier is laid, then a layer of insulation is laid, and waterproofing is placed on it.

An example of waterproofing a floor when building a bathhouse

The finishing layer is the material chosen for decoration. Its role in insulating the floor in the dressing room is often played by a floorboard; for the ceiling and walls, timber, lining, or a blockhouse are suitable. It is better not to use concrete floors - in winter such a floor will always be cold. The exception is concrete floors that have an underfloor heating system installed.

Warm floor

Heating the floor of the dressing room is an important component of comfortable bathing procedures. Modern technologies make it possible to organize heated floors that operate from different heat sources. At the bathhouse construction stage, you can create a water-heated floor, which will heat up while the stove is burning. The warm water floor system, powered by the energy of the furnace, consists of a battery tank, a heat exchanger and the furnace itself. Water circulation in the pipes should be ensured using a pump.

An example of a heated floor in a waiting room

If you do not use antifreeze liquids, the water from the system will have to be filled and drained every time there is a need to use the bathhouse, or the room will have to be heated all winter to prevent freezing.

The installation of a water floor from a stove requires taking into account the subtleties of the system. The main negative factors due to which more and more owners are inclined in favor of other types of floors:

- high heating temperature (the pipe in the floor can become too hot, since the water in it can reach a boil);

- difficulties associated with the frequency of heating (in cold weather there is a possibility of pipes bursting, even when antifreeze is poured into them);

- the need to allocate additional space (for a warm floor you will have to create a separate circuit, which will require the placement of an additional stove tank);

Additional tank for installing heated floors in the dressing room - decrease in the efficiency of the stove (heating the additional tank will require additional energy consumption from the stove, which will affect the heating of other rooms);

- significant time costs (heating the floor to a comfortable temperature using this technology takes time).

Considering that modern technologies make it possible to create a heated floor, avoiding so much labor and ensuring its safe and, most importantly, controlled operation, the design of a water floor powered by a furnace is used quite rarely. A heated floor powered by electricity using infrared technology or the convection principle is attractive because when installing it there is no need to redo an already built stove. The availability of gas and financial capabilities allows some owners to create a water floor for the dressing room, based on the operation of a gas boiler.

The process of installing a water floor in the dressing room

However, the significant investments required with this option are hardly justified when using the bathhouse once or twice a week.

Heating

Gas heating is a possible way to heat the dressing room. However, for the reasons stated above, this type of heating is more suitable for commercial premises in which the bathhouse is used constantly.

This option is also suitable if the bathhouse is part of a residential building, when the rooms and the bathhouse can be heated simultaneously during the autumn-winter season.

In a separate building, a positive dressing room temperature can be created using a stove and electricity. We are talking specifically about the organization of heating, and not about the heating that a brick oven can provide. Heating device options:

- water, operating when firing a sauna stove;

- steam, based on a stove;

- using convectors;

- using IR heaters;

- installation of a separate stove in the dressing room.

The fact that the water in the pipes will become very hot is a big plus of stove heating, as opposed to a water floor. All other disadvantages will remain. Antifreeze and a circulation pump will be required to ensure safe operation of the system. It will be necessary to equip the furnace with a heat exchanger and an additional tank, reducing the free area of the room. The stove will have to be lit in advance, taking into account the time required to heat the system and the entire dressing room.

Steam

The operating principle of a steam system is based on the movement of steam. Heat exchangers are installed in the body of the furnace, where water is heated to boiling point. Water turns into steam, which heats a system of pipes or radiators.

A simple diagram of a steam heating device

Condensation occurs there, the steam is converted back into water and flows into the tank, from where it again enters the heat exchanger.

Advantages of steam heating over water heating:

- faster heating of the room (the heat output of this system is higher, the heating rate of the room can be three times higher than the heating rate with water heating);

- ergonomics (no installation of bulky equipment required);

- safety (there is no risk of pipe rupture due to sudden temperature changes).

Considering that the best option for a steam heating device is to install heat exchangers in the body of the furnace, this option is not suitable for those who want to modernize the furnace. The existing brick structure with this heating option must initially be built with heat exchangers.

Diagram of the heat exchanger in the bath

Otherwise, you will have to dismantle the existing furnace and build a new one.

Convectors

A fairly popular method of heating a dressing room is using convectors. It is due to the wide distribution and advertising of devices that allow you to create a comfortable temperature in the room. Using convectors in practice has a number of disadvantages:

- the need for constant use (convectors do not cope well with heating a cold room; to a greater extent they are designed to maintain temperature);

- insufficient heating (if the ceilings of the waiting room are high and the heated floor is not installed, there is a possibility that the warm air from the convectors will not reach the floor);

- a question of costs (heating with convectors is not a cheap pleasure).

Otherwise, the convector heating system is quite good.

An example of placing heating convectors in a dressing room

For a small dressing room, one device may be enough, which will allow significant savings.

IR heaters

You can quickly heat up a cold room using IR heaters. The options for these heating devices are different and allow you to choose a model that fits perfectly into the interior of the dressing room. Inexpensive models of thermal curtains are unlikely to be able to quickly create a comfortable temperature. But stone samples will make it possible to create ideal conditions for its owners in the dressing room. In addition, they are economical and can retain heat for a long time.

Separate oven

A fairly simple way to heat a dressing room is to place a separate stove or household heater there. In this case, you can heat the room quite quickly. When choosing a device, you should remember that oil and ceramic heaters are very energy-consuming, and the electricity bill can overshadow the comfort of their use.

A more economical option is to install a small wood-burning boiler. A device whose lighting requires another solid fuel, such as coal or fuel briquettes, is also suitable. The price of heating materials such as firewood, coal and briquettes is low compared to the cost of electrical appliances and will allow for significant savings.

An example of a separate fireplace stove in the dressing room

If the bathhouse is still under construction and it is possible to plan the type and location of the stove, these are the best conditions for the profitable arrangement of heating all the rooms of the bathhouse at its expense, without resorting to additional heating options.

Features of installing a brick kiln

Installing a brick kiln requires compliance with its characteristic features:

Construction of a reinforced concrete foundation.

Construction of a foundation for a stone oven. Click to enlarge.

A thick layer of mortar should not be placed between the bricks to prevent it from being destroyed when heated and losing the seal of the oven. You should not unnecessarily save the solution.

During the laying of bricks, the mortar must be squeezed out. Vertical seams must be covered with top bricks.

The overlap should ideally correspond to half the length of the brick. Bricks should not be laid with the cut side facing the stove.

This precaution prevents the brick from breaking. Cast iron elements should be installed with a small gap

The upper part of the combustion door must be secured with a metal clamp.

Features of gas heating

A bathhouse with modern gas heating installed has its own characteristics associated with the possibility of gas leakage and explosion hazard:

- Equipped with an automatic safety system that stops the gas supply when the flame goes out.

- The use of a common line for supplying natural gas, an individual line for propane and butane.

- The need to comply with general fire safety requirements.

Gas heating of a large bath complex or a classic bath is characterized by simplicity and a high level of comfort.

Chimney organization

Scheme of organizing a chimney in a bathhouse. Click to enlarge.

Black baths have not been heated for a long time, and combustion products are removed through a chimney.

The chimney can be installed independently if you have the following materials and elements:

- Ceiling-passage unit.

- Passage through the roof (flush).

- Umbrella.

- Sandwich pipe.

We should not forget that the structural feature of the sandwich pipe is the presence of a heat-insulating layer designed to prevent fire in the ceiling.

However, this layer may not be enough.

Therefore, when organizing gas heating, you should not neglect the installation of additional protection for the places where the chimney exits to the street.

In this article we have revealed some features of the installation and operation of furnace equipment intended for installing a heating system in a bathhouse.

It is important to remember that when installing and operating any type of heating equipment, it is necessary to ensure that comprehensive safety measures are taken.

Construction of a brick stove

The main problem that arises when installing a brick heater is the massiveness of the structure. This requires the construction of a reinforced concrete foundation. For those who do not have experience in building sauna stoves with their own hands, the following tips may be useful.

If you put a thick layer of mortar between the brick joints, then under the influence of high temperatures it will begin to collapse and the heater will become leaky. On the contrary, a thin layer of mortar between the brick joints will negatively affect the life of the structure.

Each vertical layer of masonry must be covered with a top brick. It is advisable to make the ceilings in half a brick.

https://youtube.com/watch?v=cJLIxnSHc68

There are other nuances. So, if cut bricks are used, then the whole side should be turned inside the furnace. To ensure uniform linear expansion, cast iron elements are installed with a gap. To secure the upper part of the stove door, it is better to use a metal clamp.

Electrical

And finally, let’s look at several ways to use electricity to heat a bathhouse. I’ll say right away: take care of the electrics in this case. Since the load on thermal electrical appliances is large, the quality of the electrical wiring should not be in doubt. Consider the total load, wire cross-section, wiring diagram and quality of electrical work.

Firstly, your room can be heated using an electric heater. True, in this case you will have to take care of heating the water in the shower in advance (for example, by installing a direct or indirect heating boiler). This type of heater does not require additional arrangement of the chimney and is considered environmentally friendly.

Secondly, the bathhouse (in particular the relaxation room) can be heated using electric convectors placed on the walls.

Well, thirdly, infrared film can come to your aid - the newest type of heater, which allows you to easily and quickly create warm floors both in the house and in the bathhouse. Detailed technology for installing heated floors is discussed in other articles.

Please note that the installation of heated floors is possible without the use of infrared film, but by laying electric heating cables. They are used both in underfloor heating systems and for heating water pipes.

It is quite possible to use infrared heaters as an additional source of heat. I hung it on the ceiling and forgot about it.

Using electricity to heat a bath undoubtedly has its advantages. You can safely use all the structural elements (heater, heated floor, boiler) at any time all year round. At the same time, you don’t have to worry about fuel or worry about pipes freezing. The only serious drawback can be considered the high energy consumption.

In the case when you do not often use the bathhouse (especially in winter, rarely coming to the dacha), then the most optimal option would be a mixed heating device. For example, a stove is installed and electric heating is installed. If you decide to take a shower, rest or “stretch”, use electricity. If you decide to take a steam bath “like an adult”, turn on the stove thoroughly.

Remember. Whatever the heating in the bathhouse, if you do not use it constantly in winter, then be sure to drain the water from boilers, water heaters, pipes, toilet tank (if there is one), etc. This is guaranteed to protect them from damage, and you from unnecessary headaches.

Heated floor control unit

Self-installation of heating in the bathhouse

Installation of bathhouse heating is carried out before the interior decoration of the premises. Otherwise, there may be problems with the installation of pipes and radiators. The specificity of heating a summer cottage bath is that there is no direct contact between the lines and the internal decorative panels.

It is also important to correctly install the boiler for sauna and heating. If a brick oven will be used as the main component of the heat supply, you need to make an independent foundation for it in advance

Otherwise, its mass will push through the floor, and the entire structure will slowly sink.

The installation of an electric boiler for heating a bath is done after installing the electrical wiring. Its cross-section must be designed for the maximum operating power of all electrical appliances. An RCD must also be installed.

To fully heat a sauna attic, you need to know the following conditions:

- Ensuring fire safety. The walls and floor around the boiler must be lined with non-combustible materials. For laying pipes and chimney, special heat-resistant sleeves are used;

- The walls, floor and attic must be insulated. This is necessary to minimize heat losses;

- Due to high humidity, a ventilation system is installed. It is a mandatory element for the safe operation of gas equipment.

As an alternative way to heat the bathhouse premises, you can consider installing a warm water floor system. This will allow for uniform temperature distribution and increase the level of comfort in the bathhouse.

In the video you can see an example of organizing water heating for a bathhouse.

Features of a sauna stove with a heat exchanger

A sauna stove equipped with a heat exchanger has certain design features.

- tube supply system for coolant circulation;

- thickened body walls;

- increased volume of the heater;

- the presence of an air distributor is mandatory;

- firebox door made of heat-resistant glass.

The heat exchanger operates due to the constant circulation of water through all devices that make up the heating system in the bathhouse. To effectively use the heat exchanger, the length of each connecting pipe should be a maximum of 3 m. Especially if there is no external thermal insulation of the pipe.

Subject to fire safety rules, as well as the presence of forced ventilation and thermoregulation systems, a universal stove for baths and home heating can be equipped with a heat exchanger. The stove itself can be located in the bathhouse and connected to the living quarters of the house using a thermally insulated heating pipeline and supplying the home with hot water.

The simplest design of a universal stove is an electric stove with separate electric heaters for the stove sections with a heat exchanger and the heater.

Such a furnace can operate in several modes, namely:

- In the mode of heating the residential premises of the house and its hot water supply (DHW) while maintaining the minimum required temperature in the bathhouse premises during the cold season.

- In heating mode for baths and the entire house with hot water supply during the cold season.

- Organization of heating of the bathhouse and heater in the summer.

A similar stove for bathing and heating at the same time can be created in the form of a continuous device using natural gas or fuel pellets. Using charcoal or wood as fuel in this case is difficult and has certain technical difficulties. After all, wood or coal stoves do not provide the ability to automatically adjust the temperature. This can lead to sudden temperature changes in the heating line.

Independent arrangement of heated floors

The base of the floor is first prepared, then the screed is poured using cement mortar. Next, they waterproof the rough base using a special mastic. Then a thin layer of mortar is laid and carefully leveled.

When the mixture is completely dry, install the heat-insulating material. Take a heating cable or mat and spread it over the floor surface, connect it to power and test the functioning of the system.

If the structure works, a thin layer of solution is placed on top of the cable. After it has dried, they begin to finish the floor surface.

We make heating in the bathhouse. Commonly used options and methods

I am glad to welcome you again, curious readers, to the pages of this modest blog!

Today, succumbing to some inner call, and also taking into account questions from my subscribers, I decided to consider such a thing as heating a bathhouse.

At first glance, this formulation of the question may seem very strange. Well, really, why heat a bathhouse, which, in fact, already maintains a high temperature and creates a unique climate that is clearly different in its characteristics from the conditions outside its walls? But, oddly enough, there are reasons for this.

Baths are also different. They can be quite large in area, have many additional rooms (the heating of which, by the way, has not been canceled), and differ in interior decoration (wood, tile, etc.).

Finally, you may simply have, for example, three children who, when leaving the steam room into an unheated room, risk catching a cold. This article will discuss how to make heating in a bathhouse with your own hands. So, let's choose options...

Construction of a dressing room: preparation for new achievements

If you realize that the bathhouse needs more footage, then the best solution would be to erect a frame structure, since the walls in this case are erected quite quickly, and arranging the foundation will not require much effort - it is enough to make a shallow foundation.

A wooden frame has long ago become traditional for the Russian bathhouse, so it is necessary to properly prepare the wood. It needs treatment with several layers of antiseptic, otherwise the damp room will be captured by irreconcilable enemies - fungus and mold. Fire-fighting compounds won't hurt her either.

Particular attention should be paid to fastening elements, which must be galvanized; other options, due to their sensitivity to moisture, are not considered

The dressing room project is the first step towards defeating a cramped bathhouse. The minimum width of the room is 1 m, and for each family member (or friend) an area of 1.3 m2 is required. If the standard dimensions are 1.4x2.3 m, but only you can decide how much you need to increase them.