10/07/2019 There are many skeptics who claim that insulating a house or apartment from the inside is not the best option. But, in some cases, it is simply not possible to insulate the walls from the outside. Internal thermal insulation is becoming practically the only way that can provide a home with warmth and comfort and reduce energy consumption.

How to insulate a house from the inside, what features of the process need to be taken into account - we tried to cover the topic to the maximum. In the publication you will find the following:

- Features of internal insulation of a house: what is important to know first;

- Preparing the room for internal insulation;

- Insulation of walls from the inside with polystyrene foam; Selection of expanded polystyrene for internal insulation;

- Installation of extruded polystyrene foam for internal insulation;

- How PIR boards are installed for internal insulation;

- Selection of mineral wool for internal insulation;

Features of internal insulation of a house: what is important to know first

The main and hidden “enemy” of internal insulation is condensation. The air around us contains vapors in different concentrations. As a rule, in residential premises the concentration of vapors is often high. This is due to cooking in the kitchen, using bathrooms, watering flowerpots, wet cleaning and other reasons. Excess moisture is always removed through ventilation ducts and open windows. But in addition, they penetrate into the walls due to the porosity of the materials. When passing the wall, the vapor molecules necessarily collide with a conventional line, at which they turn into a liquid state - they condense. This line is called the "Dew Point".

With internal insulation, the dew point will always be located immediately behind the installed thermal insulation - that is, on the inner surface of the wall. When steam hits the wall, it forms condensation and moistens the wall material. The consequences of this are sad: immediately behind the insulation, a zone is formed with ideal conditions for the growth of bacteria, fungi, and mold. Thus, the premises may even become dangerous for living.

Based on what was described above, we conclude that the main task with internal insulation is to do everything possible to prevent contact of moist air with the dew point. That is, task No. 1 is to protect the inner surface of the wall from the slightest contact with steam . And this can be done quite simply. You need to do three things:

- follow the insulation installation technology;

- be sure to install a vapor barrier;

- choose the right material for wall insulation.

Thermal insulating paint

Paint for insulating walls inside is a relatively new insulating material.

It is a special coating consisting of miniature ceramic and silicone balls filled with vacuum, as well as a latex-acrylic mixture that acts as a binder.

Thanks to the vacuum present inside the balls, heat-insulating paint applied to the inside of the walls acts like a thermos, retaining heat for a long time.

Thermal insulation paint has many undeniable advantages compared to other materials:

- possibility of use in the most difficult to reach places;

- Convenience and ease of application (using a spray gun, brush or roller);

- resistance to rotting and ignition;

- absence of harmful fumes;

- excellent adhesion to various types of surfaces - concrete, metal, plastic, etc.;

- Apply in a thin layer without weighing it down.

CAREFULLY!

Before using this coating thermal insulation, it is necessary to thoroughly degrease and dry the surface.

Thermal insulation paint

Preparing the room for internal insulation

Like any other construction project, internal insulation begins with preparation. At this stage you need to do the following:

- Eliminate weak and defective areas;

- Perform antiseptic surface treatment.

First of all, you need to assess the general condition of the walls, the presence of cracks, chips in the plaster, and weak spots. It is recommended to eliminate all defects found. And the point here is not so much the quality of insulation, but rather the improvement of the performance characteristics of the walls. Correcting defects in a timely manner will prevent them from aggravating the situation in the future. After all, if the crack spreads further and the plaster falls off, then to fix this problem you will need to dismantle a large section of the insulation and redo everything again. This is not only unpleasant, but also expensive, time-consuming, and labor-intensive.

It is imperative to check the walls for existing mold and fungi before insulating them from the inside. Under no circumstances should you carry out further work until the problem has been completely eliminated. If fungal infections are found, we recommend removing the plaster in this area completely - to the base of the wall. Next, you need to treat the area with a special antifungal chemical 2-3 times. There should be no visible marks on the surface after treatment.

For pre-treatment of surfaces in order to destroy existing lesions, we recommend using the following compositions:

- Antiseptic Anti-mold Propitex 1l. A composition that contains active substances to destroy mold on wood, stone, cement and other substrates. Can be used to effectively remove spores, yeast and other types of fungi.

- Dufa mold removal solution. Instant action composition. Due to the inclusion of chlorine, it is characterized by the instant destruction of fungi and mold. Penetrates well into porous wall materials, due to which it is able to remove damage in the structure. When using, it is recommended to thoroughly ventilate the room and use personal protective equipment for hands and respiratory organs.

The next stage is priming the wall with a composition with antiseptic additives. This must be done regardless of whether fungal infections were found or not. In the future, such a composition will effectively prevent the formation of mold under the insulation. You should choose a primer only with special antiseptic properties and a long-lasting effect. For example, suitable:

- Primer EK GS400 ANTISEPTIK. Composition for porous surfaces of plasters and concrete. Penetrates deeply into the structure, strengthens, removes dust from the surface and binds small particles. Reduces water absorption and improves strength. Has a long-lasting antiseptic effect with protection against fungi and mold.

- Antiseptic Anti-mold Propitex 5 l. This composition has a long-term biocidal effect, due to which it can be used for subsequent insulation.

After the primer composition has completely dried, you can begin subsequent work. The technology for installing insulation will depend directly on the material used for wall insulation. In particular, this can be thermal insulation using polystyrene foam or mineral wool.

Selecting a material based on the type of construction

It is not advisable to insulate frame, wooden, adobe, adobe structures with vapor-tight materials. Otherwise, moisture will begin to accumulate under the insulation, which will lead to damage to wooden structures susceptible to water. Fungus and mold will begin to develop on the frame.

Suitable options for wooden and frame buildings: mineral wool, ecowool, cork. It is better to insulate stone, gas block, concrete, brick and shell rock with vapor-proof insulation materials: penofol, polyurethane foam, extruded polystyrene foam.

Choosing the correct thickness of insulating material will allow you to shift the dew point deeper into the wall without causing condensation to form.

Insulation of walls from the inside with polystyrene foam

Expanded polystyrene is objectively the most acceptable type of thermal insulation material for internal wall insulation. At the same time, only a special type of it should be used for internal thermal insulation - extruded polystyrene foam . The peculiarity of this building material is as follows:

- Increased density. Extruded polystyrene foam slabs are produced by the extrusion method - squeezing raw materials through a narrow nozzle of an extruder (special equipment) under pressure. The material forms a dense, airless structure and is characterized by increased strength, rigidity, and geometric accuracy.

- Almost zero vapor permeability. Installed as thermal insulation, XPS foam boards allow virtually no vapor to pass through them. Thus, this particular insulation is rational and suitable for internal thermal insulation. It becomes a natural barrier between the internal surfaces of the wall and the humid air in the room.

- Thermal insulation properties. Extruded polystyrene foam is characterized by an ultra-low thermal conductivity coefficient of about 0.037-0.041 W/m*K. It demonstrates excellent resistance to heat transfer, due to which the maximum insulation effect is achieved with a small thickness. At the same time, losses of useful volume from internal insulation are minimized.

- Low price. The material has an excellent cost-performance ratio.

Selection of extruded polystyrene foam for internal insulation

Extruded polystyrene foam boards differ in thickness and type of edge. For internal insulation, choose slabs with the following thickness:

- 2-3 cm for a small room area;

- 5 cm in large rooms;

- 10 cm when insulating a loggia balcony that is part of a living space.

The edge of the slabs is an important nuance that is always taken into account when choosing internal thermal insulation. Foam plastic slabs with a straight edge form a small gap when they meet, but still a gap. It is a natural bridge through which cold enters the room and vapor passes under the insulation.

For internal insulation, we recommend using only slabs with a locking joining system - L-edge . Due to this configuration, the thermal characteristics of the heat insulator are improved and vapor permeability is minimized.

Products suitable for internal insulation of houses and apartments include:

- TECHNONICOL CARBON ECO 1180x580x30 mm. Characterized by an optimal ratio of thickness and thermal insulation. Suitable for rooms with a small area, as it practically does not “eat up” square meters. Equipped with L-edge, has high heat transfer resistance.

- TECHNONICOL Technoplex 1180x580x50 mm. Equipped with excellent strength and thermal characteristics. It has an optimal thickness for insulating medium and large rooms and balconies.

- TECHNONICOL CARBON ECO 1180x580x100 mm. The most effective thermal insulation is achieved when installing such material. Equipped with an L-edge, it can be used for insulating open balconies and loggias, large rooms.

Installation of extruded polystyrene foam for internal insulation

Installation of this type of insulation is possible in two ways - using polystyrene foam glue or using dowels.

Dowel mounting:

- Fastening with dowels is carried out after preliminary arrangement of the vapor barrier. A metallized substrate, membrane or overlapping polyethylene film is installed on the wall.

- The seams are taped with aluminum tape to prevent steam from getting under the film.

- The slabs, pre-cut to size, are installed on the wall and fixed using plastic mushroom dowels with a plastic nail.

- The joints of the plates and the dowel heads are glued with aluminum foil.

- Finishing is carried out - plastering or cladding of gypsum boards.

Glue fastening:

- In this case, installing a vapor barrier is impossible, therefore, special attention is paid to the joints.

- You can use dry glue for polystyrene foam, for example, EK THERMEX or Yunis Teplomontazh. It is also permissible to use special glue in cylinders in the form of low-expansion foam.

- For better adhesion, the internal surfaces of the slabs are processed with a float until a rough surface is obtained.

- The glue can be applied evenly to the wall or in “bloops” on the slab along the edges and in the center.

- The plate is placed against the wall and pressed down. Flatness and level are checked at the same time.

- The joints are taped with aluminum tape.

- Finishing is in progress.

There is a combined method of fastening using glue and dowels. But it is rational for external insulation of a room. The foam inside will not experience increased stress. Therefore, it is enough to choose one of the options.

Izolon

Izolon is an elastic insulating material made from polyethylene with a cellular structure . It is available in the form of plates or rolls and may additionally have an aluminum foil coating.

Its main advantages include:

- durability;

- environmental safety;

- excellent shock and sound protection.

Izolon

PIR insulation is a modern analogue of extruded polystyrene foam

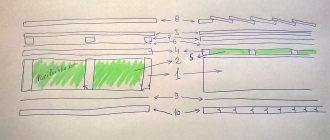

PIR insulation appeared on the market relatively recently. Therefore, they need to be considered separately. This heat insulator is a three-layer material consisting of an inner layer of polyisocyanurate foam, covered on both sides with aluminum reflective foil.

In fact, PIR (or polyisocyanurate foam) is a special type of polyurethane with a rigid structure, ultra-low thermal conductivity and increased strength parameters. Due to this, it has successfully proven itself as a heater for internal thermal insulation of any premises, from bedrooms to balconies and loggias.

A special property of this insulation is the additional reflection of heat back into the room due to the foil. Thus, the thermal conductivity coefficient decreases to an unprecedented 0.022 W/m*K, water absorption is only 1% (this is when immersed in water for a day). But the main thing is that the vapor permeability of PIR insulation is reduced to zero due to the same foil coating.

For internal insulation, an excellent solution would be to choose materials such as:

- LOGICPIR universal insulation L 1190x590x50 mm. It has the optimal thickness for medium and large rooms, equipped with an L-edge to prevent the formation of cold bridges.

- Insulation LOGICPIR Balcony L 1185x585x30 mm. It is used on the bottom of small unheated balconies. L-edge present.

- Insulation LOGICPIR Balcony L 1190x590x50 mm. Recommended for insulating a heated balcony, as well as a balcony that is part of a living space.

How PIR boards are installed for internal insulation

The aluminum surface of Pir-plates does not allow high-quality fixation of the insulation using the traditional adhesive method. In this case, the technology with plastic mushroom dowels with plastic nails is used.

The very essence of the technology does not differ from the fastening of polystyrene foam described above. After completing the installation of the last slab, the joints are glued. The gaps between the floor and the slab can be filled with polyurethane foam. Next comes finishing. Instead of dowels, you can use wood sheathing. The beam presses the insulation against the wall, after which the cladding is carried out with panels, lining, gypsum board and other materials. An example of installation can be seen in the photo instructions:

How to avoid negative consequences

The main task is to eliminate or minimize the formation of condensation in winter . To ensure this requirement, you must adhere to a number of rules:

- Select insulation with minimal vapor permeability. If this indicator is higher for the material of the walls of the house, then the moisture particles formed under the insulation will gradually come out.

- Mount the heat insulator close to the wall. With the adhesive method, the composition is applied in a continuous layer.

- Use a multilayer membrane and tape to seal joints when connecting insulation .

- Improve ventilation in the room - install forced hoods, install window valves.

- Calculate the thickness of the thermal insulation material. It is better to entrust this work to a construction engineer; you cannot rely on average indicators. The specialist will take into account all the characteristics of the house: type of building material, wall dimensions, climatic conditions of the region. It is better to take the thickness of the insulation with a small margin .

- Before installing the insulation, treat the wall with antibacterial and antifungal compounds. An antiseptic primer will do. The heat insulator is laid after the base has dried.

During the insulation process, it is important to exclude the appearance of cold bridges - they form at the joints of thermal insulation boards, as well as at the junctions of internal partitions and ceilings. The insulation must be placed with an overlap on the floor, ceiling and internal walls.

Insulating a house from the inside with mineral wool

Mineral wool is not an optimal thermal insulation material for internal insulation. There is only one reason for this - cotton wool allows steam to pass through perfectly. Because of this, described at the beginning of the article, the dew point shifts from the inner surface of the wall into the insulation itself. Condensation can accumulate in it, thermal performance deteriorate, and mold and mildew can form. However, it is possible to use mineral wool for internal insulation if all technological nuances are observed.

Choosing mineral wool for internal insulation

Mineral wool should be selected based on criteria such as thickness and environmental friendliness. It is possible to use rolled wool, which is cut to the required length directly during installation. Also, such products are produced in slabs. For internal insulation, 50 mm is the optimal thickness at which good insulation is achieved without significant loss of the usable volume of the room.

Example of suitable types of mineral wool:

- Ecoroll Plate 40. It has a relatively small thickness of 50 mm and does not contain phenol resins. Recommended by the manufacturer for internal insulation, including walls.

- TeploKNAUF For COTTAGE Thermo Plate is a modern insulation material from a well-known manufacturer, the features of which are: low thermal conductivity (0.37 W/m*K) and excellent water-repellent properties due to impregnation of the fibers with a special composition. In addition, this board has a special fiber arrangement structure, due to which sound absorption significantly increases. Thus, this insulating material is recommended for insulating the inside of walls, floors, and attics in houses located in noisy areas.

Basalt wool for internal insulation

Separately, attention should be paid to a type of mineral insulation such as basalt wool. The peculiarity of this heat insulator is not only its excellent thermal insulation properties and environmental friendliness, but also its high fire safety. Basalt fiber is obtained from natural stone. Accordingly, such a material has excellent resistance to open flames.

The fire resistance of basalt wool is an important nuance that must be taken into account when insulating the walls of wooden houses, country houses, and baths. In this case, we especially recommend choosing certified products.

These could be slabs:

- Rockwool Light Butts SCANDIC. Products that are designed specifically for insulating residential buildings, apartments and cottages. It is characterized by compliance with environmental standards (has low resin emissions, safe in residential areas). Flexi technology ensures simple installation with filling of gaps in the frame due to the spring properties of the insulation. The material is biostable - bacteria and mold do not form in it, and it is not a good habitat for insects or rodents.

- Rocklight insulation. Manufacturer TechnoNIKOL recommends using this insulation for internal thermal insulation from inside walls, floors, and attics. The material has low thermal conductivity (0.39-0.41 W/m*K). It is non-flammable, bioresistant, and due to special impregnations, it repels water well without accumulating it inside the structure. At the same time, the compressibility of the slab is 30%, which makes it possible to simplify the process of laying it between the joists and efficiently seal all the cracks and gaps.

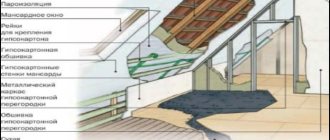

Installation of mineral wool indoors

- A vapor barrier film must be installed around the perimeter of the wall.

- A frame made of wooden blocks is mounted on top of the vapor barrier. It is not recommended to use metal profiles. Metal perfectly transmits heat and will become an artificial bridge of cold

- !!! The metal frame should be used when arranging thermal insulation from the inside of objects with increased fire safety requirements together with basalt wool. These include wooden buildings: baths, saunas, etc. !!!

- The joints between the frame and the vapor barrier are taped with tape, since when fastened to the vapor barrier, a hole from the dowel is formed.

- Cotton wool is installed in the frame and carefully compacted to avoid the formation of any cracks.

- A second layer of vapor barrier is installed on top of the frame. This creates a double vapor barrier between the insulated wall and the room.

- The fastening points and joints of the vapor barrier are taped with aluminum tape.

- The frame is covered with preferred slabs - gypsum plasterboard, chipboard, etc.

If the technology is followed and only if a vapor barrier is installed in the insulation, a good result of internal thermal insulation can be achieved. On our own behalf, we would only like to add that insulating a house or apartment from the inside is, rather, an extreme and necessary measure. It is recommended to use it only if it is impossible to install thermal insulation from the outside. If such an opportunity exists, then we definitely recommend considering its implementation as a priority. We hope that the prepared publication will allow us to avoid mistakes and carry out internal insulation as efficiently as possible.

How to insulate a wall in an apartment: options with photos and prices

Residents of apartment buildings who are dissatisfied with the fact that their apartments are constantly cold even during the heating season often insulate the walls outside. Usually this is a collective decision of several residents. For such work, you need to hire professionals, whose services are quite expensive.

But you can insulate your apartment with your own hands. In fact, it is quite simple if you follow the recommendations and select the appropriate materials. Many people choose floor insulation. But most often the optimal solution is to increase the thermal insulation of the walls. This is especially true for premises located on the upper floors of a panel house, in a corner apartment. Such rooms, due to the small thickness of the walls and location, strong winds at altitude, require maximum insulation.

Price issue

Mineral wool and polystyrene foam are the most inexpensive insulation materials for walls inside a house; the price will depend on the size of the insulated area and the method of installing the insulation. Penoplex is a more expensive material, but you don’t have to build a frame to attach it to the walls.

Choosing the type, size, thickness of insulation without specific experience and knowledge is not easy Source ursgroup.ru

The process of insulation with mineral wool and polystyrene foam is almost identical, and penoplex can compensate for its price with economical installation work.

The price of ecowool is low, but carrying out thermal insulation work will require the use of special equipment, which will increase costs.

Ecowool

Cellulose-based insulation, which is made from waste paper and paper waste. The bulk of the insulation is 80% cellulose fiber. There are additives that prevent the combustion and proliferation of microorganisms - boric acid and borax. These additives are practically not harmful to humans.

Ecowool - safe insulation Source deal.by

Ecowool is a good thermal insulation material, which in its properties is practically not inferior to others. But it has much more significant disadvantages:

- Loss of thermal insulation properties over time - ecowool is subject to shrinkage.

- Costly installation. Spraying is carried out using special equipment. Basic skills in working with the material are required to obtain the correct layer of insulation.

Features of application

Various technologies are used to insulate ecowool:

- dry backfill;

- wet spraying;

- wet-adhesive plaster.

Each method has its own characteristics. To insulate walls, the wet method is most often used, which requires the use of special equipment, as well as an adhesive.

The use of special equipment for working with ecowool Source chrome-effect.ru

Cost of ecowool

Ecowool is packaged in sealed bags of 13–15 kg. The price for 1 kg of insulation is 30–40 rubles.

But material consumption depends not only on the desired thickness of the thermal insulation layer, but also on the skills of the performer and compliance with insulation technology.

Video description

In this video we will take a closer look at insulating a house with polystyrene foam.

How safe is polystyrene foam: After filling the entire wall with insulation, it is covered with a protective vapor barrier. Sheets of plywood are fixed on top, the joints are puttied - the surface is ready for finishing.

Wall insulated with foam plastic Source stroyday.ru

Cost, foam sizes

Standard sizes of foam sheets:

- 1000x600 mm;

- 1200x600 mm.

Thickness can vary from 20 to 100 mm. The cost of polystyrene foam depends on the density of the material, manufacturer and region.

You can buy foam plastic 50 mm thick in Moscow from 50 rubles per 1 sq. m. m.

Foam plastic and penoplex

Both types of material are made from polystyrene foam, but there are some differences between them.

Polystyrene foam is 98% air, lightweight and environmentally friendly . Its main disadvantages are rapid flammability and fragility.

Penoplex is more dense, elastic and durable. It is not subject to rotting and is less flammable.

Foam plastic and penoplex