The fashion for a healthy lifestyle, a healthy, beautiful body explains the demand for gyms, cosmetic procedures, the services of nutritionists, massage therapists, etc. But many people still prefer time-tested folk methods of restoring strength and health, such as visiting a bathhouse.

Nowadays there are a large number of types of baths: in each country they have their own design features, national traditions and rituals associated with the bath are very diverse. Turkish hammam, Finnish sauna, Roman baths, ofuro bathhouse or Russian chopped bathhouse - today everyone can choose and build on their site or in their house exactly the bathhouse that attracts them with its functional properties, especially since modern technologies make it possible to carry out construction work of any complexity. Of course, not everyone can afford to build an expensive bathhouse, but this is not a reason to give up pleasure: mobile mini bathhouses based on block containers are a fast, effective and economical solution.

Bathhouse made of a metal frame. Preparation for construction

Any construction, including a turnkey frame bathhouse, begins with drawing up a project. To create a project, you need to have skills; if you do not have skills in this area, then it is better to entrust this stage to the masters. You can use ready-made diagrams.

When a project is created independently, then before starting work you need to decide on some important criteria. Important points:

- Location of the bathhouse on the territory. When determining the location on your site, consider drainage and sewerage. This is necessary in order to provide communications to the bathhouse.

- Soil at the construction site. When planning to build such a building with a swimming pool, it is important to choose a place where groundwater will not wash away the structure. The choice of foundation type depends on this factor. We have discussed in detail the options for constructing a foundation in a separate article at the link.

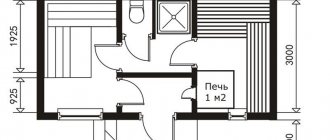

- Construction drawing and height. If you are building a frame bathhouse with your own hands on several floors, it is necessary to take into account the increased load on the frame. Even at this stage, you need to choose in advance the location of the sauna stove, as well as its design. The criterion will help determine the location and height of the chimney.

- Communications. When drawing up a project, you need to determine the location of ventilation, wiring, water drainage and insulation.

- The roof is an important element of any building; the lifespan of the structure depends on it. Therefore, when drawing up a drawing, it is worth taking into account the shape and choosing the appropriate material. After this, you can calculate the power of the overlap.

Types of furnaces

A vertical iron stove can also be made from a pipe, which also enjoys considerable success among bathhouse connoisseurs. As a rule, the principles of manufacturing and functioning of the most primitive potbelly stoves are posted on the Internet, so we will not dwell on them. But there are also original copies that need to be given due attention. These, for example, include a homemade stove in the form of a boiler with a built-in heater. This product perfectly helps solve the pressing problem - small space in the steam room, because it is a vertically located body with three chambers: a fuel chamber, a heater and a tank that helps heat the water. But due to the small capacity of the combustion chamber, the heating process must be repeated at least twice. But this is not such a big problem compared to saving free space. The volume of the fuel tank can be increased by removing the water boiler or reducing its volume.

Informative. The overall height of the sauna stove and the individual chamber depends on you. But what is most important is the presence of a spacious combustion chamber. In this case, the firewood will burn longer and will need to be added less frequently.

Bathhouse from a metal garage. Thermal insulation of garage

It is necessary to insulate garage walls both inside and outside. The simplest method of external thermal insulation is to use ordinary polystyrene foam. But at the same time, certain conditions must be observed.

- The thickness of the foam should be at least 5 cm.

- The slabs must be secured in a checkerboard pattern, since the joint of the foam seams should not converge.

- The slabs will need to be covered with reinforcing mesh.

- A solution of cement and sand is applied on top of the network (proportions: 1 kg of cement to 3 kg of sand).

- After completing the thermal insulation, the outside of the garage walls can be painted with water-based paint intended for facade work.

The inside of the garage must be insulated not only with polystyrene foam, but also with mineral wool, which is used for thermal insulation of a regular steam room. It is worth paying attention to the fact that a sauna or bathhouse installed in a metal garage will require much denser thermal insulation. It is advisable to insulate the walls in 2 layers.

It is extremely important to properly insulate the ceiling, spending more time on it if necessary. The garage design did not imply the presence of an attic, so the roof allows heat to pass through, but this should not be the case in a steam room.

The ceiling and roof also need to be insulated in 2 layers. Start with insulation with polystyrene foam 5-10 cm thick. After that, move on to mineral wool insulation with a density of 10-15 cm. Between each layer you need to leave a gap of 2-5 cm for good air exchange.

Careful insulation of the garage box

The doorway will require special attention, since garage doors are often made of iron. When insulating the gate, follow these steps:

- cover the doors with foam plastic slabs in a checkerboard pattern;

- especially large cracks, gaps and openings must be filled with mineral wool and closed with foil;

- attach slats 2-2.5 cm thick to the gate, making a kind of lathing;

- nail thick plywood or lining used for insulating baths to the slats;

- Upon completion of the thermal insulation work, you can cover the finished cladding with paint or stain.

It is worth paying attention: arranging a small vestibule at the door will allow maximum heat retention inside the room.

Advice from the master!

The design of a bathhouse in an iron garage involves thermal insulation according to the same principles. It is important to ensure that cold bridges do not form, which most often appear in the corners of the room. A bathhouse or sauna in a metal garage will require a frame that will not allow air to penetrate inside the metal walls. It is necessary to create a high-quality seal.

Stages of work

When making a vertical metal sauna stove, you need:

- Cut and process the sections of the DN500 pipe, cut an opening for the door.

- Prepare round metal blanks 5-100mm thick for the partition, bottom and lid.

- Process the cut out parts and make sauna stove doors from them.

- We weld the grates using fittings.

- We finally assemble the metal sauna stove.

First of all, we weld the partitions inside the body, then we pull the chimney pipe through the holes and weld it properly. The second step is to install the grate and weld it to the bottom using welding. The lid in the tank is made of two parts: one is welded tightly, the second on the canopies. There is a pipe cut into the bottom of the boiler through which water drains. After the stove is completely installed, screw the tap to the pipe.

It is necessary to realize that purchased factory copies are superior in appearance to homemade metal stoves, but in monetary terms the savings are colossal. Even if you purchase the materials yourself and invite specialists to manufacture the stove, your costs will still be half as much as if you purchased a store-bought version. Modern products have a thickness of less than five millimeters, which will affect their quality and performance, and visual errors can simply be hidden behind the heater.

Bathhouse made of a metal container. What is the value of a container bath

Making a bathhouse from a container box is relatively easy. All you need to do is develop and plan:

- A system of powerful insulation of metal walls, otherwise in winter the sauna from a container will turn into a glacier covered with condensation, and in summer in the sun the temperature will easily reach 70 ° C;

- Ventilation diagram of the internal space and auxiliary insulation cavities;

- Water supply for shower and steam room;

- Installation of a stove or electrical heating connection for lamps and fan drives.

All this is not difficult to do, if not for one “but”. On the one hand, it is possible to sheathe or cover a metal box with bricks, SIP panels, aerated concrete slabs, and problems with room insulation and corrosion protection would be solved. But why then fence a garden with a heavy metal body? Offhand it turns out that it is cheaper to build a bathhouse without a container insert.

Most owners choose to build a bathhouse from a container, photo, if they require:

- Build a bathhouse with a strong frame for installation on heaving loams or sandy quicksand. Buying and building a full-fledged bathhouse from a 20 English foot container will cost less than the hassle of rearranging timber or log crowns;

- Make a small-sized steam room on wheels, which can be taken for a season to a vacation spot, to a country house, or to a full-scale construction site. A bathhouse made from a 5-ton container can easily fit in the back of a Bull or a Ford truck.

Important! A container bathhouse does not require a full foundation, regardless of whether it is a bathhouse made from a 20-foot container, or whether it is planned to use several 5-ton boxes. A flat area filled with sand and gravel is sufficient.

Several container boxes, one of which is allocated for a dacha, after finishing and connecting communications, can easily serve as a full-fledged country house.

If the five-ton truck is used as an extension to an ordinary country house, the task can be simplified. For example, make only a steam room out of a container, and use the premises of a country house for relaxation and washing.

After trimming the side walls, the container body can become a frame for arranging an ordinary stationary bathhouse, built in accordance with all the rules and laws of heating engineering.

To do this, you don’t need to purchase a new or a whole container; you can buy a box with holes in the walls literally for the price of scrap metal, and it will be cheaper than:

- Pour the foundation;

- Spend half a cube of high-quality timber on the arrangement of racks and the upper and lower frame of the frame of the future bathhouse.

It will only be necessary to insulate the bathhouse on a container frame and veneer it both on the inside and on the outside of the building.

Additional filling with components

A mobile bathhouse, like a stationary one, should not deprive a person of the joy of rest and relaxation. Given the limited space, the user will still find places to relax, where he can install a sofa, a small table, or his favorite portable exercise machine. An electric stove for heating water and steam - its presence goes without saying. It's easy to fence off a shower area.

For transportation and installation in a fixed position, it is necessary to equip the container with cable hooking devices. You will have to load it onto the trawl platform using a crane.

Those who like to take a steam bath on the road equip their mobile saunas with the following equipment:

- install tiled floors;

- install an electric convection fan in the relaxation room;

- storage water heater;

- shower tray or shower cabin;

- stock of field stones;

- rational furniture.

The above list of additional kits can be considered sufficient for a useful and comfortable outdoor recreation.

DIY bathhouse made from a metal container. Container bath: where to start

So, first of all, you need, of course, the container itself, or the change house. As well as materials for steam and waterproofing, interior and exterior decoration. Today, ready-made trailers equipped for a bathhouse are already on sale. But despite this, the option to buy a container and arrange it yourself will be cheaper. And even in this case, you can be sure of using high-quality finishing materials, this is especially important for insulation.

Next, the sequence of work to create a bathhouse from a container will be as follows:

- thorough preparation of the site for construction. At the same stage, it is necessary to plan the location of the main areas of the future bathhouse and provide for the optimal placement of the drainage system;

- installation of supports under the container. They can be made of brick, which is preferable. The use of cinder block supports is undesirable, because they will quickly become unusable due to changes in temperature and humidity. It is important to take into account that for free flow of water from the washing room, a slope should be made towards the drain hole;

- insulation of the building. At this stage, you should clean the surfaces of the container walls from possible contamination and carefully seal any existing cracks. If necessary, reinforce the outer side with a metal frame. Next, outside and inside, it is necessary to cover the walls with waterproofing material and then with insulation. When choosing materials for external vapor and waterproofing, preference should be given to glassine or materials based on mineral wool, without impurities;

- Finishing work. They involve covering the future bathhouse from the outside and inside. At the same time, it is better to sheathe the outside of the bathhouse with wooden beams, be sure to treat the wood with special compounds designed to protect against fungus, mold and possible fire. And inside the room you should cover the insulation layer with waterproofing, and only then proceed with decorative finishing;

- floor installation. It is best made from two layers of boards, and insulated in the locker room and shower with the same materials that were used for the walls and ceiling;

- window installation. If it is necessary to install it, it would be advisable to install a double-glazed window. The ability to quickly ventilate the room and excellent heat-saving characteristics are its obvious advantages;

- installation of partitions. It is a frame made of beams, covered with boards and then clapboard;

- arrangement of holes for water drainage and chimney.

Electrical equipment

If a mobile sauna is installed, for example, in a summer cottage, then it makes sense to connect it to a fixed network. This requires special permission from the electrical network. They will give it. The input switching unit is usually placed in the vestibule and locked with a key. Internal wiring is carried out by a specialist. Since a metal bath container is an excellent conductor of current, the wiring must be laid using insulators that lift the wire away from the metal and from the finishing material.

This is required by safety regulations

Most often people like to travel with a mobile sauna. There is a different approach to electrical engineering here. The installation of internal wiring is the same, but designed for the voltage of a mobile portable power station. The panel input must have separate busbars for connecting an external generator.

Important: In both the first case and the second, high-quality grounding of the mobile bathhouse is necessary. This issue is not discussed

Do-it-yourself bathhouse from a metal garage. Bathhouse in the garage - how to combine these two rooms?

If you do not have the opportunity to build a sauna in your home, then an excellent solution would be to combine it with a garage, especially if the car storage room allows this. If not, it can be completed.

To equip a comfortable steam room, you will need to decide on its size. The minimum width that we would advise you to consider is 200 cm. A sun lounger for one person can easily fit into this distance. And since the bench consists of steps, three people can steam at the same time.

Regarding the height, here you need to start from the top level of the bench. It should definitely be higher than the stove. So you can measure about 120cm from the top shelf. In this format, you can sit quietly on the top shelf, and also comfortably steam with a broom.

It makes no sense to make a bathhouse less than 220cm high; it will simply be inconvenient.

Construction of a garage and a bathhouse under one roof requires certain skills and knowledge. We will describe the basic things below.

How to build a steam room?

If we take the construction of a panel bath as a basis, then wooden beams are used as the basis (frame). For example, you can take beams with a cross section of 3.2 by 10 cm. They are attached to the frame from below and above, and the beams themselves are installed in increments of 60 cm.

In places where there will be special loads, for example in a doorway, the structure can be strengthened with the help of additional structural elements.

The first ball of the frame is covered with tongue-and-groove boards with a thickness of 2.5 cm and above. Such thick boards retain heat perfectly and will provide you with a pleasant smell of wood indoors for a long time.

The next layer, after the inner lining, is a heat insulator. For this, mineral wool or fiberglass is often used. The thermal insulation layer must be covered with a vapor barrier. Do not use bitumen-based coatings under any circumstances! They will provide a nasty smell in the steam room. You can use films or foil paper.

Next, finishing is done using boards, plywood, plasterboard or brick.

Those walls that relate to the outer walls of the garage can not be equipped with a frame, but a model can be filled with planks, waterproofing can be laid, and then heat and vapor barriers, and then also sheathed.

Basic concepts of designing a bathhouse with a garage

Below we will provide several photographs of ready-made solutions, but in this part of the article we will talk about exactly those points that are worth paying special attention to.

Communications

This is the first thing to think about. Usually the garage is connected to the electrical network, but plumbing is rarely seen. So, you can’t do without it. You can, of course, carry water in buckets, but this is completely inconvenient.

Septic tank

Where would we be without draining the water? You have two options: either cut into the city system, or equip a separate septic tank.

Floor

The steam room must be equipped with a constant drain of water, so the floor surface is mounted at a slight angle to the sewer grate. It is made from boards that are installed on joists. And the structure itself is placed on brick pillars measuring 250 by 250 mm. The bottom layer of the floor is usually made of concrete, and the brick supports themselves are placed at a distance of about 60 cm.

Ceiling

Be sure to ensure that the ceiling has a good vapor barrier, and also do not skimp on insulation.

Electric furnace

If you decide to equip a garage with a small bathhouse, then an electrically heated stove will be an excellent solution.

If you do it yourself, you will need to build a housing with a steel thickness of about 3 mm and purchase a heating element. The stones are laid out on a specially equipped grid inside the furnace body.

If the bathhouse is properly designed, then stoves with a power of about 0.7 kW/cubic meter are suitable for heating.

Do not forget also about the lighting of the bath room.

Here are a few photos of a bathhouse with a garage that car enthusiasts have already sold.

Layout

I'll say a few more words about the layout. In this article we talked a lot about the steam room, but we shouldn’t forget about the relaxation room. It can be very small, enough to fit a table and chairs or a small sofa.

Also, do not forget about the shower stall or at least a bucket attached to the ceiling. After the steam room you will need to cool down.

Things like a refrigerator and TV can be installed optionally.

And so, I think, every car enthusiast knows what layout, bathhouse and garage he will choose. After all, as they say, there are no comrades according to taste and color.

Bathhouse made of a metal trailer. Bathhouse trailer: choosing a trailer

The trailer for arranging a change house is characterized by its small dimensions, which simplifies its transportation. By installing the structure on the foundation using a crane, you can get a good bathhouse. The cabins are made of metal and wood. A steel trailer is not the best choice for a bathhouse. Metal is susceptible to corrosion and requires more reliable waterproofing. A steel change house is expensive and heavy.

The best option is a sauna car made from a wooden cabin. There are no major differences in design. A wooden cabin is cheaper, easier to lift, and retains heat well. Depending on the elements used, trailers can be panel, frame, or made of timber or logs:

- For economic reasons, the panel trailer outperforms its analogues. The structure is made of a frame sheathed inside with chipboard slabs. MDF cladding is less common. Timber is used for the frame of the trailer. External cladding made of boards. Thermal insulation is laid between the two claddings: mineral wool or polystyrene foam. A roof with 1 or 2 slopes is assembled from unedged boards and corrugated sheets.

- Frame cabins are durable and more resistant to moisture. The frame of the trailer is made of thick timber. The internal and external cladding is made of wooden lining. Mineral wool is laid between the cladding, protected from moisture by a vapor barrier. The outer cladding is most often made to look like timber. The ceiling of the trailer is similarly double, insulated.

- Cabins made from timber or logs are the most reliable. The only downside is the high cost. The walls of the trailer are assembled from solid blanks 100-150 mm thick. For a bathhouse, they don’t even need to be insulated. The appearance of the trailer resembles the original log house, looks beautiful, and does not require additional finishing.