January 31, 2020

Read later

We will send the material by email

Leveling floors with cement screed is a very labor-intensive job, especially if you need to get a perfectly smooth and even surface for laying the finishing coating. This problem is much easier to solve with the help of self-leveling mixtures and get a better result. Those who choose this option will find detailed instructions on how to make a self-leveling floor with their own hands step by step. Accurate adherence to the recommendations will allow you to create both a solid foundation for any type of floor finishing and an independent finishing coating.

Self-leveling floors can serve as a finishing coatingSource materialyinfo.ru

Expert answer

A self-leveling floor, in fact, is no different from a regular screed, the only difference being that liquid self-leveling systems are used for this. The thickness of such a coating is small and most often is no more than 5 mm, and it can be a finishing coating or used in the form of a quick-hardening mixture. The latter is intended for arranging the base for floor coverings such as laminate, linoleum or parquet boards. The main advantage of self-leveling systems is that when spreading, they can easily fill existing unevenness and at the same time “bring out” the horizontal to the ideal. Of course, if you follow the technology, you won’t be able to install such a floor at an angle. The mixture will tend to take a horizontal position, or, more simply put, flow to the lowest point.

However, there is information that some home craftsmen were able to install a self-leveling floor at an angle. To repeat their result, you will have to deviate a little from the technology. The mixture is diluted with less water - and its fluidity is greatly reduced. You will have to level the surface manually - using a long spatula or a rule, having previously installed inclined beacons. The best self-leveling floor that can be recommended for arranging an inclined surface is the finishing leveler Vetonit 3000. While the mortar is setting, you will have to adjust the surface several times as a rule, otherwise slipping of the mixture cannot be avoided. I would like to immediately warn you that it will most likely not be possible to obtain a perfectly smooth “mirror” floor - the surface will need to be polished to perfection using abrasives. However, maximum accuracy and diligence will allow you to achieve the desired result - practice confirms that what you have planned is quite feasible.

The main building material at any stage of construction and repair is concrete. This is due to its technical characteristics and properties, as well as its low cost compared to other similar materials. In certain situations, pouring sloped floors may be useful. In the process of performing work, there are certain nuances that must be taken into account without fail. If the concrete screed technology is not followed, then you don’t have to think about strength.

Preparatory stage

When preparing for inclined concreting, adhere to the following sequence of operations:

- prepare the base by removing vegetation, stones, and construction debris;

- compact the surface;

- mark the site;

Careful surface preparation. To do this, debris and vegetation are removed from the site, then compacted if necessary.

- backfill with sand, ensuring a layer thickness of up to 50 millimeters;

- add fine crushed stone in a 5-centimeter layer, compacting it into a sand cushion;

- install and fix beacons used as landmarks located along the edges of the site;

- tie a cord to the beacons, emphasizing the location of the corners, geometry, and the angle of inclination of the base;

- assemble the formwork using boards, drywall waste or plywood;

- ensure the frame remains stationary using pegs and mortar.

Pay special attention to maintaining the interval between the side surfaces of the formwork. The distance must correspond to the dimensions of the vibrating screed or rule. Having completed the preparatory work, you can move on to reinforcement.

Application area

The most popular among rooms where concrete screed is laid on a slope is the bathroom. In addition, external territories cannot do without such a device.

These include entrances to the garage, personal plots, and premises of economic importance. Screed in a bathhouse or when installing shower cabins, the floor is also actively installed with some slope.

Such a screed device is necessary in places of unorganized outflow of water in order to compensate for the difference between adjacent surfaces. If you have an idea about the process of installing a concrete floor, then no difficulties will arise during the work. There are no special features. But some recommendations are worth considering in order not to deviate from the technology itself.

Criterias of choice

In addition to choosing the design of the shutter, it is advisable to select the size of the mesh so that it is convenient to lay the tiles on the floor: it is desirable that the size of the drain be a multiple of the size of the tile (including mosaics). Pay attention to the material of the case. For a shower stall in an apartment or house, plastic is quite suitable. These are the most affordable options. Floor drains made of polypropylene are more expensive, and stainless steel is even more expensive.

It is also worth choosing the height of the ladder. The minimum value is about 6-7 cm, the maximum is up to 20 cm. Among the technical characteristics, this equipment only has a maximum throughput - how many liters it can dispense per minute. Select depending on the maximum pressure that your shower can produce: the throughput of the drain ladder should not be less than the maximum amount of water dispensed. Both parameters are measured in liters per minute (L/min), so there shouldn't be any problems.

wall mounted tv cabinets

Installation features

The drainage in the required room can be completed using the following methods of pouring floor screed:

During installation, you should carefully and constantly check the functionality of the drain itself in the room. Otherwise, you will have to waste time on drilling and cleaning in the future. In this case, the level difference should not exceed 20 mm for each meter of the shower or bathtub surface. Normal operation will not be possible at higher slopes. In the future, it will be problematic to lay tiles or any other type of flooring.

Installation of a floor with a slope

The drain is most often located in the central part of the room or with some offset to one of the corners. In the first case, there will be fewer problems due to the uniform distribution and installation of beacons over the area of the room. When the drain is located in a corner, the beacons will have a different order.

Gangway installation

In general, this operation is performed before pouring the base, but we are describing the process as a whole, because in some cases the base is not poured. There is no need for this when it is possible to install a ladder in a hole in the floor (see example below).

Before pouring the base, you can use the method of fixing the ladder as in the photo below. Wooden blocks are attached with electrical tape to the top of the ladder. The bars themselves rest on the reinforcement and are set horizontally.

In any case, after installation, the drain should be covered with masking tape to prevent dirt from entering.

Base structure

We must not forget about the quality work done to clean the base from the old screed or any other coating. You can spend less effort and remove only all damaged areas, but in the future the remaining elements may manifest themselves in a negative way. For work, a hammer drill can be used to remove concrete. Particular attention is paid to the junctions of walls and floors.

If during the preparation process floor defects are identified (cracks, crevices, potholes, etc.), then they should be repaired with the prepared solution. All further measures can be carried out only after the solution has dried. Only in this case will it be possible to know how to fill a floor on a slope.

When the surface is ready, you should proceed to the waterproofing layer. The following types of materials are suitable for this:

- Coatings. They have excellent waterproof properties and are able to withstand high humidity and not allow it to pass through. In addition to the floor surface, they are also applied to walls. It will be enough to raise it to a level of 10 cm. The number of layers of the solution will depend on the type of coating being installed. All details will be written on the packaging of the material. You should pay attention to the drying time, since only after this can you begin all subsequent activities aimed at pouring floors with a slope.

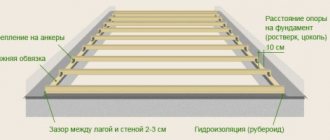

- Pasting. Presented in the form of rolls, which are spread on the base with an overlap of each sheet of 100-150 mm. Most often, roofing felt is used, which has become part of the practice of renovating an apartment.

- Emulsion bitumen. But the duration of service is no more than 5 years. It is worth thinking about whether it makes sense to spend money on such materials in order to start the work all over again over the course of several years.

Instructions for creating a decorative coating

This task in itself is simpler, since a self-leveling floor made from polymer mixtures can only be poured onto an already leveled base. Otherwise, you will have to make a thick layer, which will lead to unreasonably high costs. In other words, a decorative self-leveling coating is created after all the steps described above have been completed.

If you need a single-color colored floor, then the selected and tinted mixture is simply poured over the primed surface and rolled with a needle roller. Since it is laid in a thin layer and has good fluidity, you can do without beacons. To ensure that the solution penetrates into corners and hard-to-reach places, immediately after pouring it, you can use a spatula or squeegee to initially distribute the mixture.

The plastic mixture itself spreads over the surface Source viprusstroy.ru

To create a floor with a pattern or a three-dimensional effect, you will have to spend more time and effort. You can use one of the following techniques: pour a transparent polyurethane compound on top of a banner fabric with a pattern glued to the floor or on top of a composition of decorative elements, stones, shells, stone chips, coins, etc. laid on it.

The production of a 3D floor with a backing made of synthetic banner fabric with a pattern is shown in the video:

The second option, how to make a self-leveling floor with your own hands, is more complex: it requires multi-layer pouring with each layer drying for several days. If you immediately form a layer of the required thickness to completely cover the decorative composition, it will take even longer to dry.

The formation of layers for such a floor is carried out until the desired thickness is achieved. Source pol-inform.ru

The self-leveling floor can be used no earlier than 7-10 days after pouring.

Fixing beacons

This stage and the choice of a specific beacon option will depend on what methods of filling the screed are chosen. If the drain is located in the central part of the bathroom or shower, then the sequence of work is as follows:

- Initially, the beacon is installed in the direction from the existing drain hole to the far corner from the entrance to the room.

- Regarding this lighthouse, marks are made on the walls using a level for subsequent elements. It will be very difficult to apply a long rule in your work, since the area of the room is small. In this case, a wide and narrow spatula will be optimal.

Lighthouse installation diagram: 1 - frieze lighthouse row;

2 — intermediate auxiliary beacons; 3 — reference beacon on the wall; 4 — lighthouse rows; 5 - mooring cord for laying the lighthouse row. It is more problematic to install beacons when the drain hole is located in the dressing room or bathtub in the corner. Here attention is drawn to the fact that there will be different lengths of beacons. Of course, no difficulties should arise. The main thing is to approach the installation with all seriousness.

Required materials and tools

Concrete must be poured at an angle correctly. To work you will need the following tools:

- building level, tape measure, as well as a pencil, marker and cord for marking the base;

- concrete mixer (it is used if the solution needs to be poured over a large area or a large amount of work is expected);

- metal profile, which is used as beacons;

- rule for leveling the concrete surface even at an angle;

- vibrating tool for compacting the mixture after pouring;

- reinforcement bars;

- sling tool.

In addition to the concrete solution, the work requires waterproofing material, insulation (if necessary), and materials for grinding the base surface.

Preparing the mixture

To work, it will be necessary to prepare a high-quality solution. You can purchase ready-made options in the store, or mix everything yourself, following the proportions and recommendations. For streets and external areas, you should choose a higher grade of cement - M600. Its strength will be at the highest level. Before pouring the floor in a bathhouse on a slope, you should buy a grade of cement no lower than M400.

Fragility is ensured if the mixture has been lying for a long time and has not been used. It is very important to pay attention to the date of manufacture and service life.

To mix all the ingredients of the future solution, you need to take a concrete mixer. With its help, you will obtain a homogeneous solution with better strength characteristics.

The ratio of sand and cement M400 is 1 to 4. In the future, you just need to gradually add water, obtaining a thick slurry. There should not be any sand impurities visible.

The solution should be somewhat thicker than when installing a concrete screed in other rooms. This will contribute to the full formation of the slope. In this case, surface unevenness is allowed, since they will subsequently be eliminated with tile adhesive. If the defects in the screed are obvious and conspicuous, then cutting with diamond wheels must be used.

Adaptations

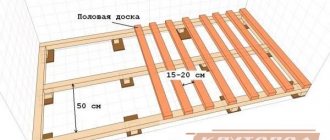

Then we install guide beacons; subsequently, the floor will be leveled using these beacons and the guides placed on them. Beacons are installed in rows along the entire room. The first row is placed 20-30 cm from the wall, the second and subsequent rows are placed at a distance of 1-1.1 m from each other. For installation, you will need a thick cement or gypsum mortar on which the guide strips will be installed. Having installed the strips, we check their horizontalness with a regular bubble or laser level in all directions. After checking and securing the guides, we leave the entire structure to dry.

Reinforcement process

A reinforcing mesh is placed between the exposed beacons, which improves the quality and strength of the poured mortar. An alternative is steel rods. The main thing is to fix them correctly and securely. They should not be located directly on the base, but somewhat raised above it. Concrete pours are suitable for this.

Currently, fiberglass is increasingly being used instead of any metal elements. Fiber allows you to reduce the total weight of the finished solution when installing on a slope, and also increases ductility and strength after drying. Despite its fluidity, the solution with fiber fiber fits perfectly even at an angle. If we take into account the cost, it will be even lower than purchasing a metal mesh.

Reinforcement is simply necessary if concrete is poured indoors not in one stage, but in several. If you bypass the laying of metal mesh, the concrete will begin to crumble and crack.

Where you need to fill on a slope

Figure 1. Pouring concrete at an angle.

Level screeding is performed in rooms for various purposes. Pouring concrete at an angle is necessary not only inside the building, but also outside. This floor installation technique is required when constructing outbuildings and other objects:

- shower rooms, saunas and baths (for convenient drainage of water);

- street areas;

- blind area around the perimeter of the building (they are made to drain water from the foundation);

- entries for cars or trucks into the garage;

- entrances to the territory of private or industrial facilities;

- descents to underground garages, parking lots;

- ramps for wheelchairs (here the screed should be as strong, smooth and resistant to mechanical damage as possible).

When pouring concrete at an angle, it is important to form a layer of increased strength and durability with the specified characteristics. To fill the solution correctly, the following requirements are taken into account: the length and width of the platform, its angle of inclination, the materials used and the quality of the mixture.

Screed installation

When there is no experience in performing such types of work as pouring the floor in a bathhouse on a slope, then you should seek help from specialists. They will tell you that installation is best done in two stages.

To begin with, prepare a solution that is thicker and contains more crushed stone. This will turn out to be a kind of base. The second layer of concrete is thicker and almost without crushed stone. The time delay between two stages should not exceed a day. If you skip more, the bottom layer will begin to dry out and will hardly be able to adhere to the second one.

Quality mixture

It is not difficult to learn how to pour a floor on a slope. Everything comes to the same conclusion with experience. But it is very important to take care of a high-quality mixture. The properties can be improved by adding various additives and components that improve the characteristics of the finished solution. The screed begins to compact on its own if plasticizers are added to the composition, and artificial fillers help increase strength after hardening, resist cracking and the appearance of fragility.

The slope angle is considered optimal up to 10-12 degrees. It will be enough for excess water to be removed into the drain in the bathroom or bathhouse. In addition, it is often possible to do without reinforcement. It is worth remembering that anyone can fill the floor on a slope. You just need to adhere to the technology and the result will please everyone.

As a rule, after a concrete floor has been laid, its surface is far from ideal. You cannot lay tiles on a “crooked” floor, as this is a violation of technology. The thickness of the glue joint should be less than 5 mm, and this can only be achieved if the floor is properly prepared for laying tiles. Mixtures for self-leveling floors can help with this.

Types of drains

The drains for draining water are cast according to the type of installation. There are three types:

The wall drain for draining water has a different design

Most often, to make a floor with a drain, point drains are used, much less often - linear ones. The installation of wall drains is generally quite a rare occurrence, since installation is possible only at the stage of major repairs, not only of the floor, but also of the walls. In addition, such devices are much more expensive.

Valve types

In addition to different design solutions, the water drain to the floor (point or linear) has different types of valves. A seal is a device that prevents sewer odors from entering a room.

The simplest seal is a water seal. In these devices, there is a bend in the outlet pipe in which water remains. It blocks odors. The disadvantage of such a system is the possibility of drying out. This happens if the water has not been drained for a long time. Drying out can also be caused by incorrect installation (the slope is chosen incorrectly) or the presence of floor heating - a warm floor in the bathroom “dries out” the water in the water seal.

Dry gates for ladders are more reliable in this regard. There are several types:

Dry drains are made mainly of plastic, gratings are made of stainless steel or also plastic. There are models with a built-in check valve. It prevents water from rising when the drainage pit overflows. When installing a floor with a drain in an unheated bathhouse, look for models that can be used in cold weather (there are some).

Dry mixtures for self-leveling floors

The main thing that needs to be taken into account when choosing a dry mixture for leveling floors is what layer should be poured. If there are potholes in the concrete screed, then it is necessary to measure the depth of the largest potholes using a tape measure. If the depth of the “pits” is 30 mm, then it is necessary to choose a mixture intended for a thick layer. For a thick layer, the dry mixture “Bolars Epreess 1050” (instructions for use) is suitable.

Self-leveling floor mixture "Bolars Epreess 1050". Layer thickness from 5 to 100 mm

When pouring a thin layer (1-10), choose a mixture designed for that thickness.

Most common mistakes

Self-leveling mixtures, when used correctly, provide excellent preparation of floor surfaces. We will list a few of the most common mistakes; this knowledge will help you avoid annoying mistakes.

- Wrong choice of mixture. Some craftsmen inattentively read or misunderstand the manufacturer's instructions. You need to know that there are no universal materials for all types of coatings; manufacturers produce a wide range of products, each with its own specific application. It is strictly not recommended to use gypsum-based mixtures under piece parquet or linoleum.

Always follow professional recommendations; there is no need to invent new technologies. Scientists worked on the development of each material for a long period of time, conducting various laboratory tests with changing conditions and technologies. Recommendations are written only after a thorough study of the issue.