The chimney is considered one of the most complex roof components in terms of design. The product must be sealed using a modern, reliable chimney seal. To isolate smoke exhaust channels, asbestos, roofing felt, cement and bitumen solutions are used. But more and more dacha owners prefer the elastic “Master Flash”.

Finishing the chimney on the roof: guaranteeing the tightness of the junction

A chimney can be found on almost any roof of a private house. It’s good when it is competently designed and built, then it can only delight with its efficiency and appearance. If during the construction process all installation requirements were not taken into account, in particular, the roof around the chimney was not sealed, this could lead to problems.

To ensure proper operation of the heating device, the connection of the chimney to the roof must be sealed. The roofing penetration is designed to ensure this.

How to seal a chimney on the roof: passage unit ↑

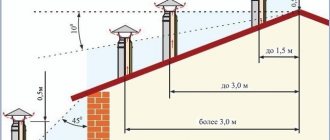

The design of the smoke exhaust passage through the roof is determined by fire safety rules. A sufficiently high temperature of the furnace gases transmitted during the exhaust process heats the chimney elements to such a value that can cause a fire in the roof. This is especially true for roofs with a wooden supporting structure. To prevent such situations from occurring, the finishing of the chimney on the roof should be carried out according to the following rules:

- A gap is maintained between the chimney and flammable elements of the roof, the dimensions of which are regulated by building regulations.

- The chimney in this area is treated with materials that help reduce the fire hazard, for example, asbestos.

- The passage of the chimney through the roofing pie is carried out, as a rule, using a galvanized metal box, in which the space up to the pipe is filled with non-combustible materials such as glass wool.

For installation along the ridge, it may be necessary to make changes to the rafter system, and installation on a slope threatens to create an additional huge pocket for snow.

It is worth noting, however, that today this problem is quite easy to solve, thanks to modern types of materials - an additional element that is placed under the ridge strip practically eliminates the possibility of leaks.

Pros and cons of materials

The space where the combustion pipe passes through the roof is a particularly sensitive structural element. If this area is not properly protected, leaks will occur during operation. The negative consequences of technological violations in the arrangement of the chimney at the junction with the roof include possible fire and destruction of the roofing system.

The most typical materials for seals are: cotton wool, filter rolls and kaolin boards.

Cotton wool, it is sold in the form of rolls or crushed powder, with short mullite-siliceous fibers. Properties of cotton wool:

- Highest heat-resistant qualities;

- low thermal conductivity and low heat capacity;

- especially chemical-resistant material;

- high resistance to vibration, deformation loads and thermal shocks;

- insignificant density and flexibility;

- strong fit to the installation site;

- fire resistance;

- excellent sound insulation.

Currently, only one significant disadvantage of mineral wool is known - hygroscopicity, which in a humid environment spoils the thermal insulation properties of the material. Self-moistening of mineral wool by 2% shifts the thermal insulation characteristics to the worse by 10%. As a result, there are established layout schemes - the use of hydro- and vapor barriers, the installation of ventilation openings. Some experts consider dusting to be a disadvantage of cotton wool. However, as a rule, no master uses mineral wool in open systems, as a result of which dusting is difficult to classify as a defect in the material.

Roll filters. Produced from fibers with a mullite-siliceous composition. They are distinguished by their elasticity and can be easily cut with a regular knife. They can be simply fixed mechanically or using an inorganic glue composition.

Asbestos or kaolin boards. They are also made from mullite silica. They show resistance to alkalis and acids, however, when working in high temperature zones, auxiliary insulation of the slabs from the influence of aggressive acid condensate is necessary.

Distinctive properties of kaolin/asbestos boards:

- Stability to the influence of moisture, steam, mineral oils;

- stability to the influence of molten metals;

- low thermal conductivity;

- elasticity and low density;

- good sound insulation;

- high electrical insulation parameters at T 700-800o C;

- stability to vibrations and deformations.

The disadvantage of such slabs is their exposure to acids at high temperatures, which requires additional insulation.

Sealing a chimney on the roof: old and new technologies ↑

Previously, sealing the roof with a chimney was ensured mainly using improvised means. Today, the market assortment includes many standardized units - they can be considered universal, since they make it possible to use them in different conditions.

Traditional methods of sealing ↑

The finishing of the chimney on the roof - also called a flashing or collar made of metal sheets - is rectangular strips with a width of about 40 cm, corresponding to the size of the chimney pipe. They are bent in accordance with the angle of passage of the chimney through the roof surface. The finishing length is calculated based on the following parameters:

- chimney dimensions;

- slope angle;

- type of finish used.

Finished flashings on the roof, if completed

- made of galvanized sheet, connected to each other with an overlay and soldered;

- made of steel sheets - standing double seam.

For finishing chimneys on roofs made of tiles or corrugated slabs, a lying seam connection is used. On pitched roofs with a slope of 30° or more, a “bumper” is installed behind the chimney - a special beam that protects its rear part from rainwater flows, forcing it to flow around the pipe.

Modern insulating materials for chimneys ↑

A protective apron is installed around the chimney. It can be done in two ways: from flexible lead (aluminum) tape or using galvanized metal, which is coated with a special polymer composition.

An elastic apron for chimneys is installed in two layers around the pipe along its entire perimeter. The bottom layer is placed under the roofing covering, say, tiles, and the top layer is placed on top of it. Then, pressing the layers tightly, they are glued to the surface of the chimney pipe. The top layer of the apron on the chimney is closed using metal profiles. A waterproofing film of the appropriate color can be purchased complete with roofs.

An apron made of steel sheets - the roof plank flooring can be insulated with roofing felt.

- In this case, before laying the apron, its edges are folded onto the walls of the chimney pipe.

- Above and below the pipe, sheathing bars are additionally laid.

- The tile elements will be laid on them.

- A groove is cut in the wall of the chimney pipe into which the upper edges of the steel apron should be inserted.

- The apron elements are attached along the perimeter of the walls of the chimney, starting from the bottom element.

- The grooves on the walls with inserted upper edges of the apron elements are filled with silicone for roofing or polymer sealant

The most reliable solution is considered to be a combination of these two methods: a metal apron and flexible sealing tape.

Master Flash - getting to know the device

Master Flash is a series of elastic sealing systems designed to seal areas where roof pipes intersect. They are used in the organization of penetrations of chimneys, sewer and ventilation risers and other communications.

They are produced in formats suitable for arranging roofs made of all known types of materials. Seals are produced for flat and pitched roofs with profiled coverings and for counterparts without relief.

The undeniable advantages of Master Flash seals:

- Elasticity, allowing you to create a tight connection to the walls of chimneys.

- Resistant to sudden temperature changes, trouble-free operation over a wide temperature range.

- Inert to ozone, resistant to oxidative processes.

- Ultra-low porosity providing excellent sealing.

- Fire resistance.

- The ability to return to its original size and shape after thermal linear expansion.

- Warranties from manufacturers are about 30 years.

- No special tools or equipment are required to attach sealing systems.

- There are no weather restrictions during the installation period.

A significant advantage of elastic seals is a significant reduction in the consumption of materials used in the organization of penetration. When using them, there is no need to lay additional waterproofing around the penetration.

Design features of seals

Roof sealing systems have replaced traditional pipe flashings. Structurally, they resemble their predecessors, but include only two main parts, these are:

- A flexible cuff made in the shape of a truncated cone from rubber with EPDM markings or from silicone. It is the cuff that ensures that the junction of the roof and the pipe is sealed, preventing the penetration of dust and atmospheric water. In the working position, the upper part of the cone tightly frames the sandwich chimney. The lower part is connected to the base of the sealing system - with a flange made in the shape of a round or square skirt.

- Flange - the base of the system, made of EPDM rubber, silicone, galvanized sheet, lead or aluminum. The silicone and rubber base for installation on a roof with large relief corrugations is equipped with aluminum strips around the perimeter. Aluminum inserts help shape the flange into a profile for maximum tightness.

The cuffs of roof seals for pitched roofs are located at an angle to the base. The cone-shaped element has corrugations indicating the contours of round holes with a clear gradation in diameter.

Corrugations are also necessary to improve the accuracy of pipe cutting: they allow, if necessary, to change the angle of inclination of the seal within the limits specified by the manufacturer.

If the imaginary central axis of the cone is located strictly perpendicular to the surface of the base, then Master Flash is intended for arranging flat roofs.

General installation principles

Flexible seals are significantly ahead of outdated methods of arranging roof penetrations in terms of technical characteristics. They can withstand a much wider temperature range without loss of quality, last longer, and require repairs less often.

In terms of ease of installation, Master Flash for the chimney is also undoubtedly the leader - the system is installed in the most basic way. To carry out the work, the contractor will not need either theoretical knowledge or practice in the roofing business.

The top of the cone-shaped cuff is cut so that the diameter of the resulting hole is 20% smaller than the diameter of the chimney being installed. The notched cone is simply put on a round pipe and carefully moves down to the attachment point. To facilitate the promotion process, manufacturers recommend wetting or soaping the surface of the chimney.

The method of fixing the flange determines the type of roofing material, depending on which the model of the sealing system is selected:

- The flange is glued to a flat roof with a roll covering using bitumen mastic or silicone glue.

- The flange base is first glued to the pitched roof with silicone, then screwed with self-tapping screws and fixed with rivets. If the back side of the flange is equipped with a sealing porous gasket, it is screwed without prior gluing with silicone.

After installation, the upper cut of the cone and the lower edge of the flange are treated with silicone sealant for reliability. A metal clamp can be used to secure the top edge.

The firmly fixed passage device remains movable. Those. in the event of thermal expansion, fastening seams and points will allow the pipe to move relative to the penetration site without losing its tightness. The cuff will behave similarly in the event of shrinkage of the walls and foundation.

How to choose Master Flush wisely

Dimensional information is not sufficient to accurately select a roofing sealant to seal a chimney, although this is an important aspect. To purchase a usable system, please note that:

- For the installation of pitched roofs with a slope from 10º to 40-45º, covered with profiled metal, non-relief roofing steel, bitumen tiles, polymer membranes, plastic, flat slate and ceramic tiles, seals with a flexible square and round base are suitable. Their installation is carried out with preliminary gluing to silicone and subsequent fixation with self-tapping screws.

- For the installation of pitched roofs with a slope from 45º to 60º with similar types of coating, seals with an elastic flange reinforced with an aluminum strip are used.

- For the installation of flat roofs and roof structures steeper than 60º, Master Flash models with an increased flange area are used.

- Penetrations for flat roofs are equipped with cuffs perpendicular to the base plane. They are glued to bitumen roofs using bitumen mastic, and to polymer coatings using a silicone compound.

- Elastic systems with metal flanges of increased area are installed on slate and tile roofs. The bases of the seals are placed according to the set of rules for installing tin aprons: the upper part is placed under the row of tiles or slate located above.

In addition, it is necessary to take into account the temperature range in which the device can operate without loss of technical characteristics. These aspects are directly related to the material from which the main part of the chimney cuff is made.

Master Flash systems are manufactured by:

- Made from ethylene-propylene rubber EPDM, which can withstand temperatures in the range from -50º to +160ºС without destruction. A number of manufacturers limit the upper limit to +140ºС.

- Made of silicone, absolutely “indifferent” to temperatures in the range from -60º to +200ºС. There are silicone cuffs, the data sheet of which indicates the upper limit of +240ºС.

The standard temperature of the flue gases at the entrance level to the chimney of a wood-burning stove is approximately 120-140ºС. For gas and liquid fuel boilers it is slightly lower. In principle, both options fully satisfy the conditions for equipping sauna chimneys.

However, according to experts, the indicated values can be considered valid if there is a distance of at least 1 m between the combustion part and the smoke exit from the stove. If not, then it is better to give preference to products made of silicone, the additional advantage of which is quite rightly recognized as its rich color and impeccable compatibility with sealing compounds. True, the service life of EPDM products is somewhat longer than that of silicone seals. But in regions where frosts below -50ºС rarely or rarely occur, they cannot be installed on bathhouse roofs. Moreover, chemists claim that synthetic rubber begins to correct at tº = +135ºС.

If you have already purchased an EPDM waterproofing sleeve for your chimney pipe equipment, but you have doubts about the actual temperature conditions, there is no need to despair.

There is a folk method of adapting a rubber device to undesirable temperature influences. Before installing the cuff around the chimney, you need to install a sleeve that creates a small gap between it and the pipe wall. Basalt wool is placed on top of the sleeve, then another sleeve is put on, the shape of which is close to the configuration of the cuff. Finally, Master Flush is installed using the standard method.

Master Flash sealing systems are produced not only for equipping the chimneys of a house under construction. The product lines include models for repair work and for installation in cases where it is simply impossible to put an elastic device on a pipe.

The cones of such products have a slit on the side with clips or a lock that snap together when connected. Models with a fastener are also used for sealing square pipes with a wall size of up to 150 mm. More solid square pipes are framed with a rubber or silicone strip on an aluminum base.

Roof chimney seal: universal insulation solution ↑

Among the new generation devices, the Master Flash roof sealant deserves special attention. It is unique in its versatility, suitable for almost any diameter. In addition, its conical design allows the seal to be installed on roof slopes at any angle of inclination. This roof penetration, due to its elasticity, allows for sealing on any roof covering.

Roofing seals of this type are made of high-quality silicone or special rubber, the operating temperature range of which is -74–260°.

Installation of roofing sealant master flush ↑

The construction of such a roof penetration is quite simple.

- The diameter of the seal ring is approximately 20% smaller than the diameter of the pipe.

- The master flush is installed a little difficult (tight), so it can be treated with, say, shampoo.

- Maximum adherence to the roofing material along the entire profile is achieved by simply crimping the flange. The joint is sealed using special compounds, after which the master flush is attached to the surface using self-tapping screws (installation pitch – 35 mm).

Installation of cuffs on tiles and slates

It is important to understand that the rubber chimney seal is suitable for insulated structures: double-walled pipes whose working diameter does not exceed 320 mm. It can be successfully used to seal the passage of ventilation pipes.

The question often arises why experts recommend using a chimney roof seal as a roof penetration for a chimney. Is a metal roof really not a reliable option? Not at all, it’s just that in a number of cases that we talked about, it is recommended to use a roof penetration sealant.

It interacts perfectly:

- With roofing materials: rubber, metal, plastic and tiles.

- Suitable for perforated roofing, where the process of sealing passages is carried out regardless of their location.

- The material is elastic and easily withstands t0 changes.

- The all-weather product is easy to install.

Also, the attractive price tips the scales when choosing. This is stated by the majority of buyers surveyed.

Chimney pipe lining: material characteristics ↑

The chimney is finished before laying the roofing material, which avoids possible damage or contamination of the coating and greatly facilitates the work.

There are many options for lining and insulating a chimney and choose it depending on the type of material used to make the chimney.

A fairly practical solution is to use clinker tiles or bricks. Dirt is not visible on them, they harmonize well with any type of roof covering.

Clinker brick

It is distinguished by its strength and resistance to sudden temperature changes and aggressive atmospheric influences. For cladding, only solid bricks are used. It is placed on a special masonry mortar, and the seams are filled with special grouting compounds.

Clinker tiles

Compared to brick, it is lighter and thinner, but it looks no worse than it. Clinker tiles are more suitable for lining very high chimneys.

The chimney can also be finished

with plaster.

This is a comparatively lighter and more affordable finishing method, but, unfortunately, not particularly durable. For finishing work, use a screed made of cement or lime-cement mortar. To increase the durability of the finish and, accordingly, its service life, the screed is coated with, say, silicone paint.

Mineral, acrylic, silicate and silicone types of plaster are considered stronger than traditional ones.

Small format cement fiber boards

– durable, resistant to moisture, UV radiation and sudden temperature changes. They are non-flammable and environmentally friendly, and are quite attractive in appearance. The slabs have a wide range of colors and are light in weight. Their surface is absolutely smooth or structured.

The chimney and roof are also lined with an extremely strong and durable natural material - slate . Depending on the deposit, shale is purple, green or graphite in color. Plates made of this material have different shapes - rectangle, arc, scale, octagon.

Heat resistant sealants

This type of sealing materials is produced on a silicate basis, which makes them stable at temperatures close to 1300-1500 °C. Some of them can even withstand temperatures of 1600 °C for a certain time.

In this case, they are dark gray or black in color and are called fire-resistant pipe sealants (the word “fire-resistant” is on the outside of the tube or package).

Some important rules when using heat-resistant sealants:

- Work with silicate sealing materials is carried out in the temperature range of +5 – +40 °C.

- The required sealing effect is achieved only in the case of rough and uneven surfaces. For this purpose, if necessary, the areas where the composition is applied are treated with abrasive materials.

- In addition, the surfaces should be degreased with acetone and then allowed to dry for 15-20 minutes.

- When the paste hardens in places where the sealant is applied, very strong and hard seams are obtained, so it is not recommended to use heat-resistant compounds for structures operating in vibration conditions.

- Traces of sealing material can be removed with a wet cloth or rag, but only before the material hardens. After hardening, this will require the use of mechanical force and some simple tools.

How is a chimney on the roof sealed?

A fireplace or stove heating are indispensable attributes of a country house or country house, which gives them additional comfort, warmth, and coziness. Even with the spread of heating devices powered by natural gas or electricity, they have not become less popular, especially when it comes to the construction of traditional Russian baths. When constructing a fireplace, the most critical and difficult moments are the removal of the chimney through the roof and the waterproofing of the joints between it and the roofing material. In this article we will tell you how high-quality sealing of the chimney outlet affects the durability and reliability of the roof.

Consequences of poor sealing

The place where the chimney of a stove or fireplace goes outside is called the chimney pipe passage or simply the penetration. It can be located in the wall or on the roof of the structure, and the second output option is considered more popular, but also more dangerous from the point of view of leaks. If the waterproofing of the seams between the stove chimney and the roofing material is not carried out efficiently, then during the operation of the roof the homeowner may encounter the following problems:

- Leaks. According to statistics cited by experienced roofers, most roof leaks occur due to gaps or cracks between the chimney and the roofing material that are not properly sealed.

- Rotting of the rafter frame. The penetration of atmospheric moisture through the seams between the chimney and the roof leads to gradual rotting and deformation of the roof frame made of wood.

- Reduced draft in the chimney. Insufficient sealing of the junction between the pipe on the roof and the roofing material leads to condensation and cooling of the chimney, which negatively affects the draft force in the system.

Note! High-quality waterproofing of the seams between the chimney and the finishing coating of the slope is the key to a long service life and structural reliability. Almost all roofing materials are equipped with special additional elements or elastic casings to isolate the point where the chimney exits to the street.

How to assemble?

The entire design of the stainless steel chimney is very simple. Therefore, you can assemble such a chimney with your own hands. Review of technical characteristics and elements of stainless steel chimneys here: https://mykaminz.ru/dymoxod/vidy/nerzhavejka/obzor-texnicheskixe-xarakteristik-i-elementov-dymoxodov-iz-nerzhaveyushhej-stali.html.

The main rule to remember when assembling is to treat the connecting elements of the stainless steel chimney pipe with special care and precision. The entire structure must be strengthened with additional elements in the form of clamps. If the chimney is purchased, then all elements must be included. Clamps are placed at each joint of the product - this is approximately every 1.5-2 meters.

Only if the assembly of the device is done correctly will it be possible to obtain a sealed and reliable chimney.

Waterproofing tasks

Waterproofing the chimney pipe on the roof is carried out during the final stage of roofing work, so some developers neglect this technological operation in order to save time or money. However, unsealed seams of parts cause leaks and accelerated wear of the structure. High-quality chimney sealing is a comprehensive solution for the following tasks:

- Improving the safety of stove heating. The chimney of the stove, especially if it is solid fuel, heats up to high temperatures, so its outlet on the roof is isolated from the flammable wooden frame.

- Increased energy efficiency. Thanks to insulated seams, heat loss through the roof slope is reduced, which leads to fuel savings and, consequently, lower heating costs.

- Condensation protection. Waterproofing the chimney allows you to maintain the temperature of its walls to reduce the process of condensation.

Experienced craftsmen note that in addition to practical tasks, sealing the joints between the chimney and the roofing material performs aesthetic functions, making the appearance of the roof more complete and organic.

Instructions on how to assemble and install a stainless steel chimney

Before starting the assembly and installation of a chimney made of stainless steel, experienced specialists carry out preparatory installation work. To do this, experts suggest using a special type of sealant that can withstand temperatures up to 100 0 C. It is with this substance that all seams and subsequent joints in the internal cavity of the chimney pipes will need to be treated.

In addition, the sealant serves as an additional guarantee of the tightness of the product, because in some cases even welding can “retreat.” There is no need to use sealant on the outer surface of a stainless steel chimney. You can find a review of stainless steel sandwich chimneys here.

The photo shows stainless steel chimneys.

Waterproofing requirements

Some time ago, craftsmen used improvised means left over from roofing work to insulate the chimney outlet assembly. Currently, construction stores have a huge range of materials, devices and devices with which you can easily waterproof a chimney with your own hands. The following requirements apply to them:

- Resistant to moisture. Since the chimney is located on the roof, it is constantly exposed to atmospheric moisture. To prevent it from deteriorating the insulation, the material from which it is made must have high moisture-resistant and anti-corrosion qualities.

- Resistant to temperature changes. The chimney of a stove can heat up to a temperature of 500-600 degrees, so waterproofing materials must have low thermal conductivity and tolerance to ultraviolet radiation.

- Wear resistance. Since the bulk of roofing materials have a service life of 15-20 years, the materials and additional elements should also last a long time so as not to have to be replaced every 2-3 years.

- Compatible with roofing material. To seal the joints between the chimney on a roof made of metal tiles, corrugated sheets and seam roofing, galvanized additional elements are used, for ceramic tiles - ceramic, for soft tiles - flexible, bitumen.

Important! Waterproofing a chimney pipe is never done with household silicone-based sealant, petroleum bitumen or cement. All materials are selected taking into account the temperature of the outer walls of the pipe at the outlet and the type of roofing material.

Types and characteristics

Absolutely all roofs equipped with a flue pipe must have excellent sealing to prevent leaks. If you use the wrong materials or violate the insulation technology, conditions will be created for the formation of condensation on the walls of the chimney. In addition, low-quality pipe waterproofing will cause an increase in pressure in the air path of the boiler or furnace, loss of draft and the formation of cracks in the chimney structure.

Traditional materials

When choosing the type of material for sealing, preference is given to metal sheets, which have good strength characteristics, ductility and ease of use. The chimney cover is made in the form of a cone and has a slope, which is determined accordingly by the slope of the roof. 90 degree cones are used for flat roofing configurations. Pitched roofs are covered with a roof with ring projections at 30 degrees.

Types of sealing agents

The presence of ready-made sets of additional elements for sealing seams greatly simplifies the task of the roofer, so waterproofing the chimney can be done with your own hands, subject to safety precautions and work technology. There are the following types of means for sealing the passage of a stove or fireplace pipe through the roof:

- Metal aprons. The most common means of chimney insulation, used for square and rectangular pipes. It is a prefabricated structure made of metal corners, which is attached to the roof slope and the outer walls of the chimney. Suitable for roofs made of corrugated sheets, metal tiles, seam roofing, slate.

It is believed that the most reliable waterproofing is achieved by constructing a multi-layer structure consisting of a rubber seal, an internal apron and an external decorative edging.

Chimney seal

Roofing seals ( roofing penetrations ) Master Flash are used for sealing ventilation pipes and chimneys, sealing and laying television cables through the roof, installing an antenna, as well as in the construction of a bathhouse or sauna.

Master flash roofing seals are made of high quality EPDM rubber or silicone, not susceptible to atmospheric and temperature changes, retaining their properties at temperatures from -55 C to +135 C (EPDM) and from -74 C to +260 C (silicone).

Roof penetration Master flash is used for all types of roofing: soft roofing, metal tiles, corrugated sheets, slate, etc. Thanks to a wide selection of standard sizes, this seal can be selected for a range of pipes from 3 to 600 mm.

Principles of canopy installation

There's no point in talking about installation. The photograph clearly shows the working parts. It is better to watch the video material presented by specialists on our website about installation possibilities.

Watch the video

Chimney cover.

But it is necessary to dwell in more detail on the types of seals and their installation. The use of silicone cuffs when arranging the structure is especially relevant.

Watch the video

Smooth roof and tension clamp with three strips.