- Cast iron

The functioning of stoves indoors or in a sauna directly depends on the installed chimney. From it, oxygen-saturated air is directed into the firebox, which is required to maintain stable combustion. The resulting smoke, soot and processed gases are removed from the room through a pipe. To regulate the combustion process and prevent heat loss, they resort to installing furnace rotary dampers for chimneys made of stainless steel and other materials.

Purpose and application

A ventilation damper is an ordinary damper, a valve, the main purpose of which is to regulate air flow. It can be used to increase or decrease air flow, and, if necessary, to stop it completely. In its most general form, a ventilation damper looks like a flat damper with a thickness of about 1 mm. It is made mainly from galvanized steel sheets.

Of course, the ventilation system will work without a damper, but will it be of high quality? After all, the ventilation of premises under any conditions and circumstances will always be the same. It’s another matter when ventilation systems are equipped with dampers. In this case, it becomes possible to completely control the flow of fresh air and reduce or increase its amount in the room if necessary.

So, having figured out what a damper is and why it is used in ventilation systems, let’s look at what they are like.

Types of ventilation dampers

Modern production offers the most diverse range of valves designed for use in ventilation systems. However, the entire existing set of gate types can be grouped into several categories:

| Category | Types of valves |

| Form | Round, rectangular |

| Design | Retractable, rotating |

| Control type | Manual, electric, pneumatic, hydraulic |

| Installation method | Installation in socket, installation using flanges |

| Material | Stainless steel, alloy steel, chrome steel |

The shape of the dampers is determined by the shape of the ventilation shaft - most often round valves are used, but in some cases rectangular valves are needed:

- There is a need to hide the gate while ensuring the minimum possible use of space.

- When installing ventilation systems that use electric heaters, since they themselves are predominantly rectangular.

What is a gate valve

A damper for ventilation is a special valve, the main task of which is to completely or partially block air flows or bulk and liquid materials. Parts of this kind, in addition to ventilation systems, are also widely used in various drainage systems, wastewater channels, etc.

There are two main types of the described mechanism: horizontal and rotary gate. The second is also sometimes referred to as the "throttle valve". Unlike a horizontal type mechanism, it is quite unreliable, so its use is resorted to only in cases where installing a horizontal gate is impossible for technical reasons.

The duct damper is most often used in chimneys made of brick or steel. To ensure complete closure of the channel, it has a perforated shape. These requirements must be met in order to comply with fire safety requirements. It is also worth noting that there are automatic duct dampers with electric drive. The process of closing and opening such a mechanism is carried out remotely by pressing one button.

Functionality

Since the damper is the main regulator of draft inside the house, the intensity of fuel combustion depends on it. To reduce the draft and intensity of the flame in the firebox, you just need to close the damper. To increase the fire, the opposite actions are carried out.

Modern damper models can be installed in both single-wall and double-wall boilers. If the fireplace or stove is not in use, then at this time the rotary damper valve for the chimney must be completely closed. Most often, craftsmen install a damper on the first meter of the chimney, since this area is not insulated. A different situation occurs with well-insulated pipes, since they should not have valves. The main danger is that when the internal and external metal expands, the gate may simply jam.

This device regulates traction

The main functionality of the damper includes:

- Partial blocking of the chimney duct.

- High-quality traction control.

- Control over the intensity of flame burning in the firebox.

Classification

Modern industry produces many types of gate valves for ventilation, which differ from each other in many parameters. Gate designs vary:

- in shape - round and rectangular;

- according to its design, the gate can be retractable or rotary;

- by type of control - manual, automatic (electric drive), pneumatic, hydraulic;

- according to the installation method - using flanges or using the method of installation in a socket;

- according to the material of manufacture - anti-corrosion, alloyed or chrome-plated steel.

The external shape of the damper depends on the structure of the ventilation system in which it will be installed. However, in private situations, only rectangular gates can be installed. There are two such cases.

Round

As already mentioned, the shape of the damper used depends on the form of ventilation. Accordingly, the use of a round damper for an air duct is only possible if its shape matches the system pipes.

Rectangular

A rectangular valve for ventilation is used much more often than round valves. In addition to pipes, it can also be installed in chimneys, drains, wastewater systems, etc.

Moreover, in some situations, only a rectangular damper can be used for ventilation. There are two such cases.

- If there is a need to hide the valve, subject to a minimum amount of free space.

- During the installation of ventilation systems, the design of which involves the use of electric heaters.

Manufacturers

In addition to the products of the PromArm company discussed above, the following companies supply their products to the domestic market:

END Armaturen is a German manufacturer of high-quality gate valves made of steel and cast iron (GG-25) in closed housings, designed for pressures of 5, 6, 7, 8, 10 bar and working fluid temperatures up to 190 °C. The bidirectional products offered for sale with a U-shaped gate with diameters from 50 to 400 mm are produced with manual and lever control.

Zetkama, a well-known Polish manufacturer on the domestic market, supplies gate valves made of cast iron EN-GJL-250 with diameters from 50 to 1200 mm. The products are intended for use in pipelines transporting liquids with a 5% solids content, installations for supplying dry materials to the pulp and paper industry, and in sewerage systems with a 35% waste content. Gate valves are designed to operate at a working medium pressure of 2, 4, 7 and 10 bar and its temperature not exceeding 90 °C.

Rice. 15 Gate valve Zetkama

FAF Vana is a trademark of a Turkish manufacturer of a wide range of shut-off and control valves. FAF gate valves are produced in bodies made of ordinary or high-strength cast iron with diameters from 50 to 600 mm. All of them are designed for a working fluid pressure of 10, 16 bar and its temperature of no more than + 130 °C. Designed for use in environments containing clean and waste water, pulp, crystallized and powdery substances, and are used for transporting substances in the brewing and food industries.

CMO is a brand of a Spanish company with headquarters and production facilities in the city of Talos, founded in 1993.

The company supplies the domestic market with a very wide range of gate valves of various designs - more than 20 items with different letters. The fittings are produced from different materials with nominal diameters from 50 to 3000 mm with all types of drives. The pressure range of all products is from 0.5 to 100 bar, working media are gases, pure and with varying contents of suspended or solid liquid fractions.

Rice. 16 ABRA gate valve

ABRA is a trademark of a Chinese company, whose products are sold in Russia by Abradox. ABRA gate valves are produced with diameters from 50 to 600 mm for pressures of 4, 6, 10 and 16 bar. The product range includes several types of knife models of different sizes, the operating temperature of which depends on the type of seals used: for EPDM it ranges from - 10 to + 95 °C, for NBR this indicator is from - 10 to + 70 °C.

Tecofi is a trademark of a French company that produces the widest range of knife gate valves in the following series: standard VG, with a through knife (VGT), for dispensing hoppers (VGS), with a square knife (VGC), with a rectangular gate valve inclined at 30 degrees (VGA) ), airlock with a rectangular knife (VGM).

Tecofi gate valve body materials are regular and ductile iron, carbon steel, stainless steel, aluminum, polyvinyl chloride (PVC). Tecofi gate valves are produced with diameters from 50 to 1200 mm, their nominal pressures are 1, 2, 4, 7 and 10 bar; in special designs, the pressure characteristics can be 25 and 40 bar. The operating temperature for EPDM seals is 110 °C.

Rice. 17 Tecofi brand gate valve

Types of gate valves

- Classic butterfly valve. Such a damper operates due to rotational movement inside the air duct. Such a gate installation consists of a metal body and a removable rotating disk. If used for a long time, it may become faulty, but replacing the part will not be difficult. You can perform this procedure on your own. Even in the absence of certain skills, you can do the entire design of a classic-type throttle installation with your own hands. This type of gate valve is easy to use and does not require constant monitoring by the property owner.

- Air damper for chimney. Refers to control parts that control the amount of fuel in the combustion chamber. Workflow management is carried out automatically.

Which material is stronger

In addition to structural differences, types of gate valves may differ in the material of manufacture. The only possible option is metal, since it is the only one that does not burn or deform at high temperatures, and over time, even in an aggressive environment, does not change its characteristics.

For production, either cast iron or stainless steel is used. It is not possible to build a damper from cast iron yourself, since this requires, at a minimum, a forge. However, you can find both nondescript and beautifully designed cast iron dampers on sale.

Cast iron rotary gate with a comfortable handle. This design is suitable for a brick chimney with a rectangular cross-section, capable of supporting the fairly heavy weight of the device

Steel products look simpler, but their characteristics are similar to their cast iron counterparts. The advantage of steel fixtures is their light weight.

If a cast iron damper for a stove chimney is installed only on a durable, permanent structure, then a steel damper is suitable for any smoke exhaust ducts - brick and steel, rectangular and round, solid and light.

Samples of a galvanized steel damper, chimney cross-sectional diameter – 150 mm. Galvanization, unlike ordinary steel, does not react to moisture (condensation) and does not corrode

When choosing a material, you need to focus on the characteristics of the chimney pipe and the features of the interior.

For a country heating stove, a modest steel valve is sufficient, while for upgrading a Russian stove in a cottage, a custom-made cast iron valve is better suited.

Design and operating principle

The gate consists of two elements - a fixed body and a movable shutter. Depending on the direction of movement of the shutter, there are retractable and rotary models. The simplest structure of a retractable valve, which is also called a knife gate valve. In it, the shutter moves perpendicular to the movement of air in the channel - a thin plate extends and easily blocks the flow. In rotary (throttle) models, the shutter rotates around its axis, gradually blocking the passage in the air duct. The simpler the structure of the gate element, the higher its reliability and longer service life. Traditionally, retractable valves are considered the most reliable and unpretentious in operation.

Rotary throttle

rotary butterfly valve

Rotary valves are not as widespread as the previous version. The operation is based on a rod, which is located in the center. A metal sheet is installed on it with rotation around its own axis. Due to this, the space is regulated and blocked if necessary.

This is a simple design that can be made on your own without any problems. But the moving part of the mechanism cannot boast of high reliability. Periodic replacement is required, which involves additional costs.

For installation, the socket and flange method is used. The differences lie in the fastening elements, which become relevant in each case.

DIY making

Independent production and installation is impossible without the following devices at hand:

- Markers.

- Compass.

- Roulette.

- Kern.

- Welding with electrodes.

- Vise.

- Pliers.

- Hammers.

- Tap and oil to lubricate the threads.

- Drill.

- Cutting and grinding abrasive wheels.

- Bulgarian.

gate manufacturing

It is necessary to have a sheet of stainless steel of the domestic brand 12×18n10t. It is acceptable to replace it with an imported analog AISI304. The cost is higher, but the service life is also longer.

The minimum sheet thickness is 1.5-2.5 mm.

Other materials you will need:

- Rod for a metal frame.

- 2 bolts 8 mm.

- 6 mm stainless steel tube.

Specifications

The design of the dampers completely depends on the location of their installation, the temperature of the air masses and the shape of the air ducts. All valves have an absolutely smooth surface, which is dictated by operation under conditions of temperature changes and the need for regular cleaning. In addition, the damper must be perforated or equipped with a slotted hole. This will not completely block the flow of fresh air into the room and will ensure the preservation of a favorable microclimate.

The gates are retractable and rotary. The first ones are used in ventilation systems with forced circulation of air flows, and are straight valves made of steel. They are installed perpendicular to the direction of flow. This design allows you to control the volume of air passage and, if necessary, change it.

Rotary models, called butterfly valves, can be installed on natural draft ventilation. The models are presented in the form of a plate fixed to an axis, and are activated using a rotary handle. The handle, in turn, is secured to the plate with a bolt and wing nut, and opens the valve 10 degrees with each turn. All valve parts are made of galvanized steel and, if necessary, additionally painted.

In supply and exhaust systems, dampers are installed in the air duct gap in front of the fan. This arrangement of the damper prevents the fan motor from overheating: when the fan starts, the damper is closed, and after the number of revolutions reaches operating parameters, it is opened. In this case, the gate acts as a starting damper, which increases the efficiency of the fan and extends its service life.

Size calculation

Even an extra gap of a few millimeters can be the cause of improper operation of the air vent.

Step-by-step steps to resolve the issue are as follows:

- First, take a tape measure to measure the size of the internal channel.

- 20-30 mm is added to the result. The result is the size of the outer frame.

- An opening for gas release is required for the finished valve.

- The position for the welding holes is also marked as accurately as possible.

Installation features

In most cases, the ventilation damper is installed immediately before the fan outlet. If their location coincides, then the design is called a starting gate, then its task is to protect the fan power unit from overheating.

You need to understand that you need to start the fan only when the damper is in the closed position. Otherwise, it will be affected by additional load, which in turn will quickly lead to failure of electrical equipment.

Important!

If you decide to install a damper in a ventilation system with a direct chimney with your own hands, then you need to know that it is quite difficult to carry out maintenance and cleaning of such a design in the future.

Like any other design, a gate valve has its own installation features. There are two main ways to install it:

- pipe-to-pipe method - the mechanism is installed in the chimney due to its design, this principle does not imply the use of additional fasteners;

- the shut-off device is mounted in front of the chimney exit or in the stove, respectively, becoming part of the overall structure; in this case, the maximum height at which the damper can be located cannot exceed one meter.

There is also another method of installing the gate - flange. When using it, you need to pay attention to two factors:

- fasteners that secure the smoke exhaust must be located at a short distance from the gate; they cannot be installed together with the main mechanism;

- all fasteners must be located exclusively on one side of the flange;

- During the installation of a flange type connection, additional sealing must be provided.

Using stove valves allows you to protect yourself from carbon monoxide poisoning. Information about the method of preserving heat in a stove is passed on from generation to generation. Everything is very simple, while the flame is burning - the damper should not be completely closed. Once the fire has gone out, the gate can be closed completely.

The valve, however, like any other mechanism, the creation of which does not necessarily require specialized tools, can be made independently without any problems. To do this, it is enough to have minimal theoretical knowledge and basic work skills.

Wafer connection

| terms of Use | Materials used |

| Temperature up to 40 degrees | Sealing tape 'Guerlain' |

| Temperature up to 70 degrees with a round duct section | Mastic 'Buteprol' |

| Temperature up to 60 degrees with a round duct section | Heat shrink cuffs, heat shrink tape |

In addition: it is practiced to seal socket joints with silicone sealants. SNiP does not prohibit their use: at the end of the list of recommended materials, it stipulates the possibility of using sealing methods not included in this list.

Flange connection

| terms of Use | Materials used |

| Transporting air with temperatures up to 70 degrees | Foam rubber, polymer mastic rope, various types of rubber (including porous) |

| Transporting air with temperatures greater than 70 degrees | Asbestos cardboard, asbestos cord |

| Transportation of acid vapors | Acid resistant rubber |

For flange connections, SNiP separately stipulates some assembly features.

- The hanger or support securing the air duct must not rest on the flange.

- All bolts should be located on one side of the flange.

- When the flange is in a horizontal position, the bolts should be on top of it and the nuts on the bottom.

Adjustment

When operating heating units, an important aspect is the correct adjustment of the traction force, which affects the efficient operation and safety of the heating system. The sliding element, even with full penetration into the chimney channel, does not completely protect the bathhouse from the penetration of carbon monoxide. Closing is carried out after the end of the firebox, the firewood should have time to burn out and become covered with an ash layer.

If this is not followed, there is a risk of inhaling harmful gaseous substances. As carbon monoxide leaks out, it fills the room. It should be remembered that installing draft control devices (vane, deflector, weather vane) does not exempt you from regular cleaning of the pipe. If equipment is not cleared of soot in time, unpleasant consequences cannot be avoided.

It is necessary to carefully monitor the condition of the chimney structure and the presence of sufficient draft force.

To control traction, a formula has been developed for calculating the optimal value for the gate element, which is called the “alpha” coefficient. When setting the required value, uniform combustion of wood materials is ensured with minimal ash formation.

Self-installation of a gate valve

If you need to mount a damper for a brick kiln located in the house, you should do the following:

- first of all, lay out the first row of the chimney pipe from bricks;

- then make the next brick row and make a hole in it for a gate valve;

- In one of the bricks laid out in the second row, you need to create a groove for the handle for the valve of the fireplace or stove.

A groove is a recess or slot into which an object of a certain size can fit. This is a simple job that anyone can do.

The gate is also installed for heating boilers. It allows you to control the removal of gas particles, which leads to increased efficiency and economical consumption of fuel resources.

The slide damper is the main guarantee of fire safety when organizing stove heating; it is an essential part in the ventilation pipe, chimney and boiler.

A damper is one of the types of regulating and closing devices designed for installation in a ventilation system. The design of this element is not at all complicated; in terms of its operating principle and appearance, the part is similar to a furnace valve for a pipe.

The main component of the damper is a metal sheet that blocks the air flow if necessary.

How is traction adjusted?

Adjustment is the most important aspect of operating furnace equipment. With proper control of this process, you can achieve the highest efficiency from the device, as well as save the health of the residents of the house. Even if the partition is completely blocked, there is still a gap for the movement of exhaust gases. It must be closed exclusively in the final part of the firebox (after the wood has finished burning and an ash layer has formed on it). According to fire safety requirements, the damper must have a small hole through which weak gas exchange occurs.

Considering the importance of this element, it is necessary to choose trusted manufacturers. Such as the manufacturing company Ferrum.

Frequent errors and problems during installation

There are several problems that most owners of this design face:

- Install handles that do not allow you to track the position of the valve.

- Carbon monoxide has nowhere to escape, there is no hole.

- The surface is not smooth enough.

- The use of thin grades of steel or stainless steel with a low nickel content. Such products quickly fail due to deformation under the influence of high temperatures.

- A metal chimney with a cast iron part inside. Such parts are not compatible with each other.

- A valve is installed in areas with insulation. Thermal expansion causes jamming.

Video description

Video example of installing a damper in a chimney of a brick kiln:

When installing a damper in a pipe, the following series of problems and errors may arise:

- Installation of the valve in a part of the chimney duct with external thermal insulation. As a result, the mechanism will overheat and jam.

- Installation of a cast iron model in a steel pipe. Under the influence of the large weight of the damper, the chimney is deformed.

- A poorly made valve is made of thin metal. Such a product will quickly burn out or bend under heat.

- An uneven internal surface of the gate will lead to frequent jamming and poor-quality operation.

- A valve plate without a technological hole (for easy purging to avoid the accumulation of carbon monoxide in the furnace), necessary to comply with safety regulations.

- Installation of rotary models with adjustment handles that do not make it possible to control the position of the sliding plate.

Advice! To extend its service life and trouble-free operation, the damper must be cleaned regularly. The retractable plate and guides must be periodically lubricated with a special anti-corrosion compound. The rotary analogue requires cleaning through the chimney with a special brush.

Why do you need a chimney damper?

Chimney damper

The required elements of stove heating are chimney dampers. Traditionally, their main function was to retain heat. A closed valve blocked the possibility of combustion products escaping into the chimney. As a result, the furnace not only heated up, but accumulated heat, due to the fact that hot flue gases could not escape outside and gave up their thermal energy to the channels. But life, as we know, does not stand still and neither does technological progress. Therefore, it became possible to further increase the efficiency of a brick kiln using an element such as a chimney damper.

What does the gate give?

Just like traditional chimney dampers, a damper allows combustion products to open or close access to the chimney. In addition, it performs several other useful functions:

- Regulates traction.

- Reduces fuel consumption.

In old furnaces, a gate, as a rule, was not installed. If you want to make your stove heating more efficient, you should install this simple device. Modern furnaces, as a rule, already have a flange with a gate included, but it can also be purchased separately. The simplest gate can be made with your own hands.

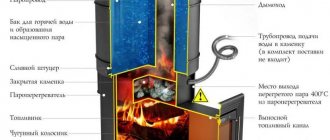

Before buying or constructing a damper for a chimney with your own hands, it is worth understanding the principle of its operation. During combustion of the furnace, the valve partially blocks the cross-section of the pipe, allowing flue gases to escape through the pipe and, at the same time, regulates the draft force. After stopping the fire, by completely closing the chimney damper, the release of gases stops. Regulating the thrust force simultaneously allows you to control and change the intensity and speed of fuel combustion. In modern heating devices, a damper must be installed in boilers.

The gate valve differs from a traditional gate valve in several ways:

- Resistant to high temperatures (withstands heating up to +900 degrees).

- Corrosion resistant.

- The ability to block the chimney during combustion up to 85% of its cross-section.

- Good thermal conductivity.

Drive types

To regulate the operation of the mechanism, different types of drives are used. This is due to different pipe capacities and different densities of the working medium.

- With the manual method, the valve is adjusted using a handle or lever. It is mounted on pipelines carrying liquids and gases of low density without solid inclusions.

- Electric drives allow you to adjust the position of the damper without physical impact. Such valves are used in large enterprises to regulate the flow of viscous, granular media with solid inclusions.

- Valves with pneumatic actuators have the most complex design. They provide the best tightness and are mounted on pipelines with remote adjustment and allow manual control.