As practice shows, a person can do a lot, even one who has never encountered anything before. The main thing is that he has a desire, and he can always figure out how to find opportunities. The article will discuss how to make a bathhouse out of a trailer, which is often left behind by builders on the site. They no longer need it, and a zealous owner will always be able to find a use for such a “gift.” Its purpose is temporary housing in which people can be provided with a comfortable stay. Carriages are made from wood, metal, or a combination of these materials.

Furnace structure

An electric heater or a metal wood-burning stove must be installed in the steam room (it requires a separate base). To accumulate heat and create steam, it must be equipped with a compartment for stones, which must be checked before using in the sauna. To do this, light the stove and heat the stones. After 500-600 degrees, soot begins to burn out of them.

Pour hot water onto the stones: 70 degrees (never cold - the stone will crack), steam will begin to release. The main thing here is to determine whether the steam is pure or with an admixture. To do this, you can hang a white sheet in front of the stones and, after the steam has dissipated, see whether it is clean or not. If dirt or soot is found on the sheet, it is better to remove such a stone, it contains many volatile fractions that are harmful to the body. Select broken and crumbling stones and leave the strongest ones.

Make an opening on the ceiling for the chimney. Protect the places where it passes from fire. It must be taken into account that there must be at least 38 centimeters from the chimney to the wooden parts.

The length of the stove chimney is of no small importance. Too short will overheat and will not provide the required traction.

Double-circuit chimneys of the “sandwich” type have proven themselves very well: they are more fireproof and condensate harmful to the stove evaporates faster. Be sure to install a water tank on the chimney pipe - this is the fastest and most economical way to heat water. You can also use an electric broiler. Do not forget about protective metal sheets where the stove is installed (on the floor, adjacent walls and ceiling).

For the steam room, you cannot use materials such as linoleum or wooden slabs, since when the air is heated, they release substances that are bad for human health. The same applies to plastic. Tile finishing is also not recommended, as it can crack at high temperatures, and touching it can cause severe burns. It is better to cover the outside of the change house with a more airtight (windproof) sheathing, for which use an OSB board, and only then perform decorative finishing with clapboard or siding.

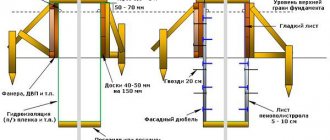

External thermal insulation must be done in the following sequence (from outside to inside):

- exterior decoration;

- waterproofing;

- insulation;

- polymer hydrobarrier placed on the cabin.

To use the sauna safely, you should take care of a high-quality ventilation system. In this case, it is necessary to adhere to the rule: the influx of fresh air should always be located below the outflow of used air. If the ventilation in the cabin is not organized correctly, then in the steam room you begin to inhale what comes out of you and, as a result, feel discomfort.

What and how are they built from?

The toilet appears first on the site, and then the change house

Almost all cabins are built using frame technology. The building materials for the frame are wooden beams of at least 100*150 mm or a profiled metal pipe 60*60*2 mm.

For cladding, the choice of materials is much wider. Use:

- edged board;

- sheet material - plywood, OSB, chipboard;

- profiled sheet;

- siding.

In any case, the cladding is done on both sides - outside and inside. The outside can be metal, but the inside is often made of either lining or stuffed with plywood or OSB.

One of the options for a garden shed

Thermal insulation is laid between the two skins. Although the structure is temporary, spring and autumn, and sometimes summer nights, can be very cold. Therefore, without insulation there is no way. Any insulation can be used. Better - mineral wool, cheaper - polystyrene foam. Extruded polystyrene foam has the best characteristics, but also the highest price. Just when choosing insulation, keep in mind that foam plastic almost does not muffle sounds, so those who are particularly nervous will not be able to sleep. Therefore, the optimal choice is mineral wool. What layer? If you think about it, then in central Russia, preferably 100 mm, but at least 50 mm.

Please note that the floor also needs to be insulated. Especially the floor. There is a lot of pressure from below. Therefore, it must be double: first, rough, on top, across the board, logs are laid, insulation between them, and then the finished floor.

Foundation for a trailer

The design is selected based on the dimensions of the building and the quality of the soil.

There are four main types:

- tape;

- columnar;

- pile;

- slab.

The sauna trailer can easily be placed on a shallow columnar base. The “power” of the structure is not that great, so you can do without reinforced concrete tape. In addition, it should be borne in mind that the building can be moved at any time to another site.

Dismantling a columnar base will then cause much less hassle than a monolithic reinforced concrete one. Please also note that the price and labor costs spent on the construction of a columnar.

The height of the base is 300-400 mm from the ground. This will make it possible to make additional bedding to insulate the lower part of the trailer.

The cheapest option is a foundation made of asbestos-cement pipes. However, its durability and strength are questionable. A pile foundation is installed in swampy and heaving areas, but its cost will be very expensive. It’s not difficult to build a base for a trailer with your own hands; the main thing is to follow the construction technology.

Preparation

Below are instructions for the preliminary stage.

- Clear the selected area of debris and bushes, and if necessary, uproot trees.

- Make markings using pegs and cord to mark the center lines. Place the columns of the future foundation at a distance of 2-3 m.

- Remove the fertile layer of soil in the areas of future foundation columns.

Manufacturing

- Make a sand and gravel bedding 100-150 mm high. Tamp it thoroughly with moisture.

- Build a columnar foundation on it:

- Made of red brick or concrete blocks. Conduct masonry with bandaging of seams using cement-sand mortar.

- For a monolithic columnar foundation, formwork must first be made. A reinforcement cage should be installed inside. The distance between it and the outer wall must be at least 50 mm.

- Waterproof the base by covering it with roofing felt.

- Install a frame made of wooden beams with a section of 150x150 mm on top. Secure the beams together with metal corners or make corner joints “into a paw”, “half a tree” or others.

Check the foundation with a horizontal level, if necessary, place linings under the frame.

Dimensions

The dimensions of cabins today can be very diverse.

This depends on various factors (for example, purpose, budget possibilities, space on the site, necessary to accommodate temporary residents of the space). Conventionally, cabins can be divided into three categories: small, standard and large. The parameters of each type may vary. For example, a block container with a vestibule can be 2.4 m wide, 5.85 m long and 2.5 m high. These parameters may change: on sale you can find options with length, width and height parameters equal to 580x230x250, 600x250x250 cm. Large modifications are found with vestibules, which can be up to 1.5 m in length.

Two-room construction-type cabins are usually 6 m long and 2.4-2.5 m wide. The window openings in them are usually no more than 90 cm wide. Each room here has 3 m of usable space. Small houses can be 3 m long and 2.35 m wide. Their height is standard and is 2.5 m. Sometimes the width of such temporary huts is only 2 m.

The most compact versions of temporary buildings have a height of 2 m, which does not allow the installation of metal doors. Large options can reach a length of 6.8-7 m. Individual projects reach a length of 9 m. The standard width of cabins varies from 2.3 to 2.5 m on average.

However, if the project involves the presence of a veranda or terrace along the entire length, this increases the overall width by 1.5 m. Other typical options include cabins with dimensions of 3x3, 6x3, 9x3, 12x3 m.

Preparatory work

Many owners of suburban areas prefer to make. You need to start with the project. – 6x3 m. The basis can be a standard diagram of the frame of the cabin. And then add the necessary partitions. Typically, a bathhouse consists of a steam room, a washing room and a dressing room. If the size of the cabin does not allow you to arrange all these rooms, then remember that a bathhouse is primarily a steam room, and the remaining rooms are organized based on the area of the building. Subsequently, you can add a terrace to relax after taking wellness treatments.

When calculating the materials for the construction of a steam room from a cabin, it is necessary to take into account that it consists of two rectangles, say 6x3 in size, which are connected to each other by vertical posts every half a meter or 80 cm, depending on the location of the door and window openings. The beam for the base should be 10x15 cm thick, and for the vertical posts - 5x5 cm. The front posts of the change house should be half a meter higher than the rear ones to create a slope for the future roof. Next, we will need 10x4 cm boards for the floor and ceiling, and we will also prepare lining for cladding the walls inside and out. Don’t forget about good insulation, hydro- and vapor barriers, roof sheathing and roofing materials.

Before you start building a bathhouse, you need to select a place for it on the site. In this case, it is necessary to provide for some points, since special requirements are imposed on the construction of a bathhouse. The change house must be located at least 1 m from the neighboring property and within 15 m from the neighbors’ wooden structure. Failure to comply with this rule may result in penalties and litigation.

Making the floor

First, we construct a subfloor from boards treated with an antiseptic. We lay them out as tightly as possible to each other and attach them to the frame with self-tapping screws.

Subfloor in a change house Laying film Mineral wool On top - another layer of film Finished floor boards

We spread a waterproofing film over the boards. We attach it to the joists using a construction stapler with staples.

We nail additional logs to the base for laying thermal insulation and attaching the second layer of boards. We fasten the logs in increments equal to the width of the selected thermal insulation material. Mineral wool, a relatively inexpensive and time-tested thermal insulation material, is well suited for floor insulation.

We lay insulation in the space between the joists. We fix a layer of vapor barrier material on top. A stapler with staples will help us with this again.

We lay the finished floor boards. We attach them to the joists using self-tapping screws. Finally, we varnish or paint the floor.

Preparatory work

Before starting construction, it is necessary to carry out a number of preparatory work, which includes preparing the site and materials.

Place

When choosing a place where the future steam room will be located, special attention should be paid to SNiP standards:

The bathhouse should be located at a distance of 8 meters from buildings made of non-combustible materials, from 15 meters from wooden buildings and from 20 meters from reservoirs. It is important to locate the bathhouse on an elevated area. The bathhouse should be placed near reservoirs so that the drainage from it does not fall into the reservoir. It is necessary to position the bathhouse structure so that it can be seen from the windows of the living space.

It is also advisable to choose a place from which steam and smoke from the bathhouse do not reach the residential building.

Once the site has been selected, you need to prepare it. First of all, it is necessary to clear it of debris and remove the top layer of earth to fill the foundation or install pillars.

Tools and materials

To build a bathhouse with your own hands, you will need the following tools:

- axe;

- hammer;

- screwdriver;

- level;

- saw;

- shovel.

It is necessary to understand that this is the minimum set of necessary tools that you can use to make a bathhouse from a change house with your own hands, but for more comfortable construction it is also recommended to acquire an angle grinder, a furniture stapler, a spatula and a tape measure. In addition, we must not forget about the fasteners - self-tapping screws, nails and metal corners, which are necessary to connect the bathhouse frame.

When choosing materials, special attention should be paid to thermal insulation

It is important to choose ones that can be insulated both external and internal walls

Interior decoration of the bath

The functionality of the structure is important. But interior design also affects mood. The washing room and relaxation room are distinguished by a low temperature when compared with a steam room. Therefore, wood needs to be protected from dampness to a greater extent.

The cladding made of pine, larch, and cedar is beautiful in appearance and resistant to moisture. Linden cannot be ruled out.

Features of the cabin

This term refers to a temporary mobile structure that serves as an auxiliary room for domestic needs. They are usually purchased before the construction of a house on a plot of land begins. The cabins can accommodate workers or be used as a warehouse for storing building materials.

Based on the type of construction, such buildings are divided as follows:

- prefabricated trailers;

- mobile structures made from block containers.

Mobility means easy transportation of a building from one place to another on its own wheels or using a trailer. But the concept of mobility includes, in addition to the possibility of moving the house, its transformability. That is, the change house can be turned into any room, for example, into a bathhouse.

These buildings can be wooden or metal. They are assembled using different technologies. Therefore, they are divided according to these characteristics into several types.

Types of buildings

| They are like this | Characteristics |

| Wood frame. | They have a frame more than 5 cm thick. They are covered with high-quality and environmentally friendly materials. Thermal insulation layer 50 mm. |

| Wooden panels. | The cheapest in cost. They consist of a frame with a cross-section of up to 5 cm and are covered with chipboard, fiberboard or plywood. Insulation is minimal or completely absent. |

| Wooden from timber. | This is a log house made of beams of at least 10 x 10 cm, between which inter-crown insulation is laid. Does not require additional finishing. |

| Metal frame. | Made from a wooden frame covered with corrugated sheets. Lining is used inside. The space between the interior and exterior finishes is filled with heat-insulating material at least 5 cm thick. |

| Metal block containers. | This is a monolithic metal structure. The inside is lined with wooden lining, under which a thick layer of insulation is laid. It has excellent thermal and waterproofing characteristics. |

To turn an ordinary change house into a bathhouse, you need to take care of insulation. The walls, floors and out of the change house should be formed according to the pie principle: external cladding, a layer of waterproofing, thermal insulation, at least 5 cm thick, vapor barrier film, interior finishing.

A trailer bathhouse has many advantages.

- Possibility of construction at any time of the year.

- There is no need for a building permit.

- Does not require serious financial expenses.

- Warms up quickly.

- Withstands earthquakes up to 9 points.

- Short construction time.

- Does not require a strong foundation.

- Possibility to transport from place to place.

- Small quality requirements.

- Undemanding to soil.

- They take up little space on the site.

- Reliability and durability.

The disadvantages of a bathhouse made from a cabin include its small internal dimensions, which excludes the possibility of steaming with a large group. Due to their light weight, transport structures may not withstand strong cross winds. Therefore, these need to be strengthened with additional spacers. Also, such trailers require repeated treatment with various antifungal and antiseptic compounds.

Other bath rooms

When the premises are planned correctly, the procedures will benefit the body.

It’s comfortable in a bathhouse if there is somewhere:

- steam;

- relax;

- wash.

Many people equip a bathroom (small in size) at the expense of other premises during the construction stage. Although an analogue is a dry closet. There is no need to connect communications to it. If there is enough space, then a bathroom is welcome.

The dressing room is a connecting link; entrance is provided in any direction. Bath complexes are equipped with additional premises:

- swimming pool;

- billiard room;

- gym.

The sauna is becoming popular; it is distinguished by dry air. The temperature there is high and the humidity is low. Therefore, you will think about where to organize a sauna. A change house or a block container will do; you need to choose which is better and faster to equip.

Functionality

Bake

The main part of any bathhouse, since without it it is impossible to create a real steam room. Most often, heater stoves are used, when stones are placed on the top of the stove to accumulate heat.

The most practical location of the stove is the firebox outside the steam room. In this case, there are all conditions for creating a safe zone around it using a metal sheet. The heater should be installed on a brick base, and the roof must be insulated with asbestos and other non-combustible materials to avoid fire.

Configuration

The rooms in the bathhouse trailer are located one after another.

- An entrance that must have two doors and a vestibule between them.

- The locker room is usually not heated, but electric heating can be installed.

- A rest room or dressing room with or without a shower.

- Steam room.

Sewage and water

Hot water in the shower can come from an electric boiler, or a heating radiator can be diverted from the stove. In the first case, the shower can be used without lighting the bath. Water is discharged either into a separate pit on the site or into the central sewer system. Cold water should be supplied to a separate storage tank located inside the trailer.

Installation

Installing a large structure requires significant effort. You can't handle it on your own. You have to rely on special equipment that is available in construction companies. They will deliver and install without any problems, which guarantees long-term operation.

Small structures can be brought on a trailer yourself and installed with the help of friends.

The quality will be worse, but it will be affordable. It happens that it is not possible to pick up an object. Then specialized construction companies will ensure safe storage of various cabins and modular containers.

Install windows and doors after roofing work. The entrance frame and door leaf are fitted tightly. If cracks appear, seal them with foam. The doors are being painted. A canopy is hung over them. Make sure that there are no gaps between the window blocks and the wall.

Choosing a trailer

Typically, cabins are made of either metal or wood. A wooden trailer is ideal, since metal is highly susceptible to corrosion and is much more demanding in terms of thermal insulation, and, in addition, metal cabins are more expensive than their wooden counterparts. So, the best option would be a bathhouse made from a wooden trailer.

Having decided on the choice of material, you should pay attention to the elements from which the change house is made. Wooden trailers can be panel, frame or made of logs

The most economical option is a bathhouse made from a panel trailer, but you will have to pay for the cheapness with quality - you will be lucky if such a structure lasts more than two years.

The most reliable will be a trailer made of logs, but it will also be the most expensive. The golden mean is the frame structure. Its most significant drawback is the smallest area of all three types of structures.

House projects

If you look at the options offered by sellers of cabins, it seems difficult to settle on anything. There are small standard houses at a very affordable price, and there are large, two-story structures that are impressive in their scope.

One of the most popular projects is a house of two cabins. They are installed at a distance of 3 m from each other. If you equip such a house, then it will comfortably accommodate not the smallest family, and this will happen due to the fact that the bathroom and kitchen will be in one part of the house, and the recreation area will be in another. Since the cabins are located at a certain distance, this space also needs to be used according to plan. Usually, the owners make 2 walls that unite the parts of the country house, and a common roof is installed on top.

The space between the cabins is also used to accommodate cars. If the owners decide to do just that, then instead of one unifying wall they will equip a gate. As an option, the middle part is used as a mini-workshop or storage room.

Other projects.

Chalet style house. From one simple construction shed you can get a quite interesting version of a chalet-style home. The basis of such a structure can also be a sea container.

Conclusion

A do-it-yourself bathhouse from a trailer is an interesting opportunity to use auxiliary structures. In the video presented in this article you will find additional information on this topic.

The question of how to make a bathhouse out of a change house is relevant among many compatriots. And this is not surprising, since cabins are relatively inexpensive and available to most people, especially if used buildings are purchased.

So, what is the technology for converting a cabin into a bathhouse?

Initially, it is necessary to insulate the roof, floor and walls in order to reduce their thermal conductivity to a minimum.

The interior space is lined with wooden clapboard. Next, the lining is treated with antiseptic agents in order to subsequently eliminate the possibility of mold formation and, as a consequence, destruction of the wood.

The total area of the room is divided into 3 equal parts: a steam room, a dressing room and a washing area.

After this, a sewer pipe is installed, which is diverted to a drainage pit or to a septic tank. Through this pipe, water will be discharged from the washing compartment to the outside.

The electrical wiring is well insulated to prevent the possibility of short circuits due to high humidity.

A wood-burning or electric stove-stove is installed.

Water and electricity are supplied.

It is important to take into account the small dimensions of the bathhouse based on the change house and therefore make the doorway of all doors as tight as possible in order to prevent the penetration of excess moisture from the washing compartment and steam room into the dressing room. In addition, the bathhouse is a potentially fire-hazardous structure, and therefore all doors must open towards the exit, that is, outward

About security

Manufacturers are required to certify standard designs of transportable bathhouses, but I strongly recommend requesting a certificate. You never know...

Let me explain for those who are not in the know. If the bathhouse is certified, it means that all the requirements related to the standards for its safe operation have been met. In particular, insulation of the structure, protection of electrical wiring, calculation of ventilation.

It is mandatory to carry out priming of the material from excess moisture, hydro and vapor barrier, impregnation with antiseptics, protection from biological activity (wood insects, fungus, mold), increasing fire resistance (treating wood with special compounds - fire retardants) and so on. In general, everything is in accordance with the requirements of regulatory documents for such baths.

Of course, if you wish, you can build it with your own hands, using decommissioned kungs, construction trailers on wheels, and even large-volume tanks (you know the kind, barrel saunas) as a basis for the structure. Just, first, ask about the price of ready-made ones. Perhaps it will be inexpensive for you, and you will save time.

Equip the inside of the carriage as a steam room

First, connect the lighting, then separate the dressing room from the steam room. Cover the floor with roofing felt so that the waterproofing layer of the material protrudes along the walls by about 15 cm. Punch a hole in one corner of the steam room and insert a tube into it to drain the waste liquid. The ceiling of the car with the floor and walls should be reliably insulated, except for the place where the stove is planned to be located.

Lay out the stove, leaving a hole in it for the chimney.

- Ensure reliable protection of pieces of furniture that may be located near the stove to prevent fire.

- Arrange furniture, install a door with windows, firmly isolate the dressing room from the steam room, prepare a place for the drainage hole.

- Ask an experienced stove maker for advice on how to properly install a ventilation device for the stove. The floors in the car should not be cold, reduce heat loss to a minimum.

The underground part will ensure the strength of the structure

If you need to use a temporary shed for a season or two, then you can do without a reliable foundation.

In other cases, it is necessary to determine the type of soil, freezing depth, groundwater level, because they affect the height of the foundation. On dry soils, it is recommended to deepen it by half a meter. On wet fine sand, sandy loam, clay, loam, lay to the freezing depth (no less).

| What is the foundation like? | Material | ||

| Stone, concrete | reinforced concrete | wooden | |

| Massive (entirely covering the entire building) | + | ||

| Tape (made in the form of continuous strips) | + | + | |

| Solid slabs | + | ||

| Pillar (individual pillars) | + | + | |

| Box structures (consist of horizontal slabs that are rigidly connected to vertical walls) | Sometimes + | ||

| Pillar-chairs | + To prevent them from rotting quickly, they are treated with an antiseptic | ||

To connect the structure with the underground part of the booth, use a hinge connection, secure it rigidly, and place it on top (support it).

Lighter structures, temporary ones, are sometimes placed on pillars-chairs.

Tile is suitable for loose, marshy soils.

Piles are indispensable on difficult soils, near bodies of water. They are rarely installed in dachas.

In the form of continuous strips

This underground part is ideal for heavy baths. Installation on heterogeneous soil, sandy, clayey, rocky is possible. They dig a trench around the perimeter. Cover with coarse sand (15 cm), spill with water, and roll with a board. Then - a layer of crushed stone and gravel. Determine the width of the tape. Marked with metal rods.

Arrangement of formwork (from boards, plywood) begins from the corners. They are checked with a laser level and a rangefinder. They must be straight. Otherwise, distortions of windows and doors will occur.

To give elasticity and reliability, pins, channels, and reinforcing mesh are placed in the formwork.

Pillar base

Pillar construction is used for frame houses and small wooden buildings. Not suitable for clayey, mobile soils. Blocks are often used for supports. To suit their size, holes are dug around the perimeter and inside the markings. Rubble and sand are poured. The bottom is compacted. They use the principle of fired brick masonry. The supports are strengthened with cement mortar.

If the pillars are made of concrete, then formwork is required for each. The pits are made in increments of 1.5-2 m. In order to evenly distribute the load of the bathhouse on the pillars, they are connected with a beam.

General for foundation soles

The construction of each underground part has its own nuances. However, there is a commonality.

It consists:

- in the correct choice of location, putting the site in order;

- in carefully determining the dimensions, taking into account the edge (the part of the foundation protruding beyond the building);

Marking is carried out using a rope, construction meter, and pegs. Precision is important. Otherwise, deformation of the walls cannot be avoided.

Second stage equipment

- Preparing sand and gravel for a “pillow” 15 cm thick. Compact it and water it.

- Make a mound of columnar base “pillow” on top. Using concrete blocks or laying bricks, bandage the seams with a cement composition with the addition of sand. The formwork is prepared in advance, a frame is installed inside it from fragments of reinforcement, and a monolithic foundation is obtained. The outer wall and frame should be separated by a five-centimeter gap.

Then cover the base of the foundation with roofing felt for reliable waterproofing. A frame is installed on top, which is made of beams, their cross-section is 15x15 cm. Use metal corners for fastening. Before installing the frame, all its wood fragments should be treated with an antiseptic.

When laying the foundation, use a building level to check the level surface; if necessary, install a lining of bars under the base of the frame. The carriage must be placed on top of the foundation using special equipment. Install the car with a slight slope on the side where the steam room is located so that the flow is directed into the drain hole.

Car interior inside

Typically, the bath compartment of a carriage contains four compartments:

- The vestibule corridor occupies the space up to the door of another room.

- Steam room.

- Shower in the dressing room.

- The section where they undress.

The place for clothes is never heated in order to save money. In order for the water to heat up, you need to place a barrel in the carriage to store water, which is heated from the stove, or connect an electric boiler. The arrangement of the bathhouse depends on the preferences of the owner and his financial wallet.

Finding a comfortable corner in the country house

At the very beginning, you need to decide on a place that would be suitable for arranging a bathhouse in a trailer at the dacha:

- If the dacha plot is located on the bank of a river, close to a lake or near a reservoir, then you should install the trailer fifteen meters from the shore, closer is not recommended - this trick makes it possible to protect the trailer from being flooded during a flood.

- If there is a highway on one side of the site, then you can put the trailer on the other side, away from the road.

- When the site is a small space, you can connect the carriage with an outbuilding, summer kitchen or garage. Foreign odors will not appear if ventilation is installed correctly and good insulation is taken into account.