The bathhouse is a popular and, let’s not be afraid of this word, fashionable trend in the everyday life of a modern person. It’s very nice to build a bathhouse on your own. And even if it is not possible to do it yourself from start to finish, then at least you need to develop a bathhouse project on your own. Who else, if not oneself, needs to lay the foundation of the future structure. At least on paper.

What is it needed for

According to the norms of the current domestic legislation, the bathhouse is classified as an auxiliary outbuilding, the construction of which, to meet personal needs, does not require a separate permit. If the construction of a bathhouse is for commercial purposes, then the situation there is radically different, but we will consider the option of individual construction for personal needs.

If permission is not required, then there is no direct need to develop the project. This is in theory. In practice, the project is needed, and there are several reasons for this:

- It allows you to make a preliminary visual assessment of the future construction and find its strengths and weaknesses;

- The preliminary plan of the bathhouse will help to rationally place all the necessary elements in the internal volume, lay them out at the design stage, coordinate them and link them into a single system;

- It will help you pre-calculate the required amount of building materials for its construction, and draw up an estimate for future construction;

- A correctly reproduced drawing of the premises will make it possible to accurately estimate the labor costs during construction, evaluate your own strengths and calculate those involved.

With the current level of technology development and the availability of information, ready-made bathhouse projects can either be ordered from specialized design organizations, or spied on the vast expanses of the World Wide Web. However, anyone can develop it on their own. Why not try it.

We decide on the technical specifications

Projects require preliminary development of technical specifications.

That is, it is necessary to immediately determine the approximate area of all the premises of the bathhouse, within its perimeter in a one-story configuration or floor-by-floor if the structure of the bathhouse is made on several levels. At the level of technical assignments, water supply sources, wastewater disposal and disposal systems, the presence of swimming pools, basic materials for the construction of walls and roofing and other fundamental points are determined. After the technical specifications have been formed in a more detailed format, at the level determined by the adopted design, we can proceed to more detailed applied design.

Option 5

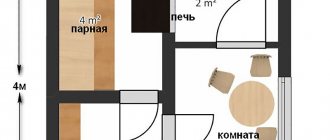

For those who prefer maximum functionality with a minimum of frills, the optimal option would be a log bath house with a total area of 40 m², shown in the figure. Such a compact and visually attractive building will be a great place for a relaxing holiday with friends, or a place for pleasant solitude against the backdrop of nature.

Log bath house 40 m² (Fig. 28)

The key feature of the project is that the customer is given the right to choose the construction material (rounded logs or hand-cut wood). An aesthetic and moderately democratic building will fit perfectly into any landscape and will look good in any corner of the site. The dimensions of the bath house allow it to be placed even in limited space. The interior spaces are also well thought out: a living room with a kitchen (total area 10.5 m²), a large washroom with a separate bathroom, a spacious steam room (6 m²), a comfortable vestibule and a terrace (7.4 m²), where a large company can easily fit at a festive table .

Bath house project (Fig. 29)

The convenient location of the premises inside the building, the compactness and presentability of the building are the undoubted advantages of this project. The original decoration of the veranda and snow-white window openings add a special solemnity to the bathhouse.

You can examine in detail a one-story bath house from all angles using the visualization in Fig. 30, 31, 32, 33.

We are developing the foundation

Based on the general design of the future bathhouse laid down in the technical specifications, a foundation is designed, which, among other things, must take into account the bearing capacity of the soil at the construction site. The most commonly used types are:

- Strip foundation - has a good load-bearing capacity even on soft soils; it distributes the load quite rationally even under buildings with two floors. However, it requires a decent amount of excavation work with the disposal of excavated soil and the laying of a concrete, often reinforced mass, with subsequent maturation within 30 calendar days. Expensive, but durable and reliable;

- Columnar foundation - under certain conditions, is an affordable alternative to strip foundation, but requires excavation of soil and laying of monolithic or prefabricated reinforced concrete in much smaller volumes. At key points, metal or asbestos-cement pipes are laid to a sufficient depth, which are subsequently concreted and tied around the perimeter with lightweight concrete structures. Reliably performs its functions under small buildings. A structure based on such a foundation should have a fairly lightweight structure;

- Screw foundation - characterized by quick installation, which can be carried out almost year-round. Does not require excavation work. There is no need for maturation time, as is the case with monolithic concrete.

If the technical specifications specify the construction of a brick kiln, then it is necessary to calculate the arrangement of the foundation for it. To do this, the volume of the future furnace must be multiplied by the specific gravity of a cubic meter of finished brickwork; as a rule, this figure is in the range of 1430-1970 kg. If the resulting figure exceeds 800 kg, then a full-fledged foundation for the furnace must be designed. Its depth should not be less than the depth of the main foundation, and the stove foundation itself should not be tied to the foundation of the bathhouse. Thus, when separated, they are less susceptible to dependent deformation.

The technical specifications, as a rule, provide for the organization of a simple rubble concrete foundation. Sand is poured onto the base of the pit, spilled with water and compacted, then crushed stone of a fraction of 20-60 mm is laid and compacted in the same way. Sand acts as a damper cushion.

After this, monolithic concrete is poured onto the cushion with the exit through the formwork of the head of the base to approximately a height of 100-120 mm. The construction project necessarily provides for the treatment of the furnace foundation and the main foundation with waterproofing materials in accordance with generally accepted standards.

Attention! The distance between the finished floor level and the foundation level should be 60-80 mm. To gain nominal strength, freshly laid concrete must mature for 21 days.

Main premises

A bathhouse often consists of a dressing room, a steam room, a washing room, a bathroom and a relaxation room.

Waiting room

Functions of the waiting room:

- A buffer climate zone that evens out the sharp temperature transition from outside to temperature in the bathhouse.

- A storage area for firewood where it is often dried.

- Dressing room and clothing storage area.

- Very often, a dressing room combines functions and rest rooms.

The most common bathhouse designs that one encounters involve combining the main functions of a dressing room with the function of a rest room. In this case, its area should be 2-2.5 times larger than the area of the steam room.

To obtain natural light, it is rational to place window openings on the western side. The height of their lower edge should be in the region of 1000-1200 mm from the floor level. It is reasonable to place the doorway on the south side and its dimensions should be standard, within 800x1850 mm. with the door opening outwards.

Steam room

Generally accepted and time-tested and practice-tested schemes provide for calculating the area of a steam room based on 1 sq.m.

for one person. The usable area very much depends on how visitors to the steam room will take the procedures: sitting, lying, reclining. Based on the minimum requirements, a steam room designed to simultaneously accommodate three people who will steam while sitting should have dimensions of 1500x2000 mm. The bathhouse layout being developed must take into account not only the usable area, but also the entire area of the steam room in which the stove will be located, its enclosure, passages to the shelves, etc. Practice shows that the largest volume is occupied by a stone wood-burning stove.

Important! If you use a metal stove, it should be located at a distance of at least 1000 mm from the wall of the room. In addition, the outer walls of such a furnace must be fenced with masonry, which will prevent burns from direct contact with its surface.

In addition, paired compartment schemes must take into account the following technical points:

- Wall and ceiling cladding material. Based on its thermophysical features, it will be possible to calculate the depth of thermal insulation of the room and the use of special design techniques to improve its efficiency.

- Arrangement of the ventilation system. As a rule, its functions are performed by a ventilation duct. Ventilation works reliably using two channels: exhaust and supply, spaced apart in height. The cross-section of the exhaust duct should not be smaller than the supply duct. Compliance with this requirement will allow you to avoid the negative phenomenon of “overturning the ventilation stream.” In other conditions, a ventilation duct can replace a double-glazed hinged window with an opening size of at least 370x350 mm. For effective air exchange, it should be located on the wall opposite the stove. Preferably on the west side for better use of natural light.

- Also a doorway that should be designed with a high threshold. Such a natural cutoff will prevent cold air from “leaking” under the door and creating a “negative convention” effect and reducing the overall thermal efficiency of the steam room. The doorway, according to established practice, has dimensions of 1600x750 mm. Even original baths usually have a door that opens outward.

- There is no need to provide a combination of a steam room and a washing room. This is a direct path to reducing the quality of steam. Irrational increase in humidity and decrease in temperature. As a secondary consequence of such a decision, one can note increased fuel consumption to compensate for the violation of the general water-temperature balance in the steam room.

Washing area or shower

As we have already noted, such a room must be equipped separately and have a dedicated volume in the overall designed system. A bathhouse, the plan of which provides for the installation of a font or a swimming pool, can have them in the washing department. Then its total area increases by an order of magnitude.

With minimal needs for three people, the washing area should be about 2000×2000 mm. This is enough to place containers with hot and cold water and take water procedures. Windows should be provided at a height from the floor level of at least 1550 mm, which will significantly reduce the risk of drafts.

The window opening should be 1.5 times larger compared to a similar opening in the steam room. The remaining requirements are similar: double glazing, placement on the cardinal points for efficient use of natural light, etc. The project may include equipping a washing room with a shower compartment. In this case, a separate area of about 950×950 mm or more should be allocated for the shower.

Attention! In the washing compartment, the doorway is somewhat larger compared to the steam room. It is 1800×800 mm. This is due to more lenient requirements for the thermal efficiency of the room and more stringent requirements for ease of use and comfort of movement in general. The threshold, however, must be designed high.

Bathroom

A bathhouse according to an individual project provides for the arrangement of a bathroom equipped with one toilet. The depth of such a room should prevail over its width. In digital terms, dimensions of 1200x800 mm are sufficient for most cases.

Other auxiliary premises

The bathhouse may also contain other rooms that perform additional, rather than primary, functions. This could be a recreation room with sleeping places, a billiard room and others. Naturally, one should take into account the fact that fairly easily designed premises will, in the future, as the project is practically implemented, require a significant amount of financial resources.

A word from Experienced! The use of a dual-purpose stove-heater is very interesting. The firebox of the stove, designed like a fireplace, is located in the relaxation room, and not the flow-through heater - in the steam room. At the same time, we should not forget that the option of a non-flowing heater can only be implemented in the version with a steel stove, which has the necessary heat transfer characteristics.

How to do it?

If a brick partition is planned in a wooden bathhouse, then before this the structure must be stable, that is, shrinkage.

To connect the main walls of the bathhouse with the partition, pieces of reinforcement are mounted at one end into the wall and at the other into the masonry joints. The diameter of the rod should be 6 mm. If a brick partition in a bathhouse is placed near the stove, then it would be correct to leave a window for the combustion channel. The progress of masonry work is carried out in the following order:

- The first thick layer of mortar is laid, leveled with a trowel, and creates the base of the wall. We need to give it time to catch on.

- Then another layer - thinner - under the first row of bricks. The mortar is applied to the ends of the outer bricks with a trowel, pressed tightly against the wall and excess mortar is removed. Using a stretched string, the evenness of the rows is controlled. And the level shows horizontal and vertical.

- The laying of the second and each even row begins with halves of material. This - dressing - is done to evenly distribute the load.

- Every 3-5 rows, pieces of reinforcement or steel wire are placed on the cement to provide strength.

- In a similar way, the entire wall is driven completely up to the ceiling. The remaining gap is filled with small pieces and fragments soaked in solution. Small cracks are sealed with tow.

- If the bulkhead is planned with a door, then the frame is set up in advance. It is attached to the brickwork using steel strips. The bricks are laid close to it. Do not forget to control the horizontalness and evenness of the masonry by moving the stretched string higher.

- After the solution has hardened, the seams are sanded.

Between the sink or rest room and the steam room for ventilation during drying, you can place a small hole that can be closed during bath procedures with a shield or plug. After the partition is erected, the wall on the washing side is tiled, and in the steam room it is insulated, thermal insulation foil is laid and covered with clapboard.

General layout of the bathhouse within the site

Structures must comply with key principles within the layout on the site:

- The distance from the bathhouse to the residential building must be at least 10 m. On the one hand, this is an immutable requirement of fire safety rules, on the other hand, it ensures normal smoke removal during heating of the sauna stove in various weather conditions;

- The distance from the fence to the bathhouse structure must be at least 3 m. This condition will allow fire crews to have access to the entire perimeter of the bathhouse structure during the occurrence of force majeure circumstances, in other words, a fire;

- The structure of a bathhouse located on the shore of a natural reservoir. It should be about 15 m away from it.

Project of a traditional Russian log bath

The bathhouse made of solid logs corresponds most closely to the bathhouse traditions of the Russian people. Its main types:

- Barked log. With this type of pre-treatment, only the bark is roughly removed, and not everywhere. This pre-processing method is very fast, however, it has a number of disadvantages. For example, in places where the bark has not been removed, pests usually hide, then placing such a bathhouse inside requires additional refining and finishing;

- Scraped log. This is a more in-depth, although rather primitive, type of processing, during which the top loose layer of wood, the bast, is removed with a special cutting tool. Together with it, all the flaws that are inherent in the debarked log are removed. Such structures are more susceptible to treatment with protective materials and are much more durable. They retain all the charm of a classic traditional antique bathhouse;

- Planed log. With this type of processing, it is already possible to use power tools with rotary knives, with the help of which deep layers of wood are removed. The construction scheme of which is based on the use of such material has some of the highest thermal insulation properties. In addition, planed logs respond very well to the use of protective compounds;

- Lafetted log. Two opposing edges are removed from the trunk, resulting in the formation of well-matching areas between adjacent elements. This material is distinguished by a high degree of stacking of elements during installation. It is not easy to build a bathhouse, the designs of which are based on the use of laminated logs, due to the high labor costs for preparing high-quality and well-matched sites;

- Rounded log. Has the most attractive appearance. All elements are the same, standardized sizes. In artisanal conditions, such processing is impossible to carry out, because it requires the use of rather complex industrial equipment. The surface of such material is perfectly treated with protective materials to a great depth, which ensures a long service life of such structures.

Finishing a small washroom

It is best to decorate the inside of the bathhouse with wood. Even if the outside of the building is brick, it is recommended to make the interior, including walls, floors and ceilings, wooden. This material will make the bathhouse a truly healing place of relaxation and rest, filling it with the pleasant smell of wood.

The following timber products are most suitable for finishing a bath:

- Linden;

- aspen;

- pine;

- ash;

- oak;

- larch.

If you want to feel a resinous, tart woody aroma during bathing procedures, choose coniferous species, which are also the healthiest.

The video shows an example of finishing a bath:

Application of laminated timber

The technology of laminated veneer lumber is often called Scandinavian, although it is most widespread in Finland, which is not related to Scandinavia. The use of such, frankly speaking, expensive material has a number of undeniable advantages:

- All traditional qualities of wood are preserved.

- All elements have excellent geometric and linear characteristics.

- This material is not prone to deformation in adverse weather conditions.

- Glued laminated timber is perfectly processed with protective materials to a great depth of solid wood, which ensures its long-term use in open atmosphere conditions.

Brick baths and their features at the design stages

A brick bathhouse has both advantages and disadvantages. Let's start with the good:

- Brick is a very durable material. The use of facing bricks eliminates finishing work;

- It has thermal insulating properties;

- Its use allows you to implement the most complex and elegant projects for a bathhouse;

- Not susceptible to rotting, swelling, damage by pests and microorganisms.

Now a few fly in the ointment:

- A bathhouse built of brick is more expensive than a wooden one;

- Requires the use of a well-thought-out ventilation system and reliable vapor barrier to avoid moisture condensation and dampening of the masonry;

- High load on the foundation;

- The appearance of a brick bathhouse is inferior to a log bathhouse in the traditional sense.

Making a brick partition

Layout of a 4x6 bathhouse with separate sink and steam room: the most successful completed projects

The partition in the bathhouse between the steam room and the sink can also be made of brick. Here it is better to use ½-brick spoon masonry (or, alternatively, a whole brick). Such a structure will weigh quite a lot, so to lighten it, you can use hollow bricks.

Making a brick partition

Stage one. Preparation

Before starting work, it is necessary to prepare all working surfaces. The plank covering is removed from the floor all the way to the foundation, then everything is cleaned with a wet broom. Next, the workplace is equipped with good lighting, all items that are not needed for work are removed from the room. The contours of the structure are outlined.

Stage two. Solution

To work you will need the following equipment:

- sieve;

- Sander;

- shovel;

- mixing tank.

Tools for work

Step 1. First you need to sift the sand to clean it from foreign objects. A sieve is constructed from a fine mesh chain-link mesh and 4 beams. The sand is carefully sifted.

Step 2. Next you need to take care of the mixing container. It can serve, for example, as an old iron barrel, cut lengthwise into two parts. The barrel is firmly installed for ease of operation.

Step 3. Mixing proportions – 3:1. First, you should fill in six buckets of sand and two of cement. Water is added and the solution is mixed with a shovel. This volume of solution is enough for about an hour of work.

Step 4. The solution is mixed to the consistency of thick sour cream. At the end of kneading, it will begin to harden and shrink, but there is no need to add water - just stir it once every 15 minutes.

Bathhouse projects made from building blocks

A building block is a piece of building material endowed with shape, features and certain linear dimensions.

cinder block

The filler is usually granulated slag obtained by quenching a hot blast furnace with water. Not a very good material in terms of environmental safety. Good strength characteristics, durability and thermal insulation qualities.

A big advantage is the ability to independently produce cinder blocks with a minimum set of equipment and technological skills. The construction of walls from such material is easier than brickwork. Due to its fairly high specific gravity, it requires a good foundation. Absolutely non-flammable. It has moderate water absorption.

Aerated concrete

An innovative material that is distinguished by thermal insulation characteristics and low specific gravity. The load on the foundation is much lower than that implied by the use of brick, bentonite or cinder block. It is distinguished by fairly simple installation and is satisfactorily cut into smaller elements.

The material is expensive; in addition, the construction of a number of individual sections with a radius profile, for example, arches, is associated with objective difficulties.

A feature of the use of all mineral-based building materials is the use of reliable hydro and vapor barriers. In addition to their tendency to form condensation, such materials often have a high level of water absorption, which requires mandatory response measures. Taking into account the fact that aerated concrete blocks are a promising building material, we provide a summary information table of the main standardized sizes:

| product name | Thickness, in mm. | Height, mm | Length, mm |

| Straight block | 200 300 200 | 250 250 300 | 625 625 625 |

| Block with handles and tongue-and-groove interface system | 375 400 | 250 | 625 |

| Straight block with handles | 300 375 400 | 250 | 625 |

| Straight gas silicate block with tongue-and-groove interface system | 300 375 400 | 250 | 625 |

| Straight aerated concrete partition block | 150 | 250 | 625 |

| Unified partition gas block | 100 | 250 | 625 |

| U-shaped block for lintels and monolithic chords | 200 300 400 | 250 | 500 |

Material selection

The construction of a Russian bathhouse from logs or beams requires the choice of high-quality material. So, the most suitable would be larch, spruce, and pine. All this wood is characterized by longevity and ease of processing.

- Larch. A very hard wood. It can last up to 300–400 years. When constructing baths, it is often used only in the lower balls due to the fact that it is quite difficult to process. Bathhouses made from larch logs do not require special protection with antiseptics. Since this breed is quite expensive, it has not been used very often lately;

- Pine. A Russian wood-burning bathhouse is most often built from this type of wood. Pine logs are mostly straight, hard and easy to process: trimming, planing, making the necessary notches. The resinous species of this tree have a natural barrier against water;

Pine bathhouse project - Spruce. In the construction of wooden structures it is used less frequently than pine, but is also quite common. It has a slightly loose structure, which has a more favorable effect on thermal insulation. A little more difficult to process than pine;

- Other types of wood. When building a bathhouse from logs or timber, you can also use less common wood materials, aspen, for example. The main thing is that the tree is alive and healthy.

Bathhouse and cottage

What's the secret:

- With a slightly increasing load on the foundation and its area remaining unchanged, the useful volume of the bathhouse increases by 70-75%;

- The optimal angle of inclination of the roof should be approximately 50-60 degrees, then the under-roof space is used most efficiently;

- The use of spiral staircases and staircases with a turning platform, which are provided for by a well-designed design of a bathhouse for a summer residence, allows us to minimize the loss of space on the first floor;

- The size of a land plot of 6 acres, at the same time tax-free, is a direct and effective way of rational and sensible use of the territory.

Bathhouse with terrace

A terrace is an area adjacent to the main building that has a roof and is made of the same building material as the main building. It can be open or closed, with the maximum possible glazing area. The use case is determined by the warm season. The project, which includes a terrace, has a number of design features that must be taken into account:

- The foundation of the bathhouse should not have a rigid connection with the foundation of the veranda. This requirement also applies to the roof. The absence of a rigid connection will avoid deformation disturbances in the event of uneven subsidence of the main structure and the terrace due to their different weights.

- The structure should reflect the different floor heights of the main structure and the terrace. So, very often the floor level of the platform rises above ground level by 500-550 mm, at the same time, the floor level of the bathhouse should be higher than the level of the terrace by another 50-70 mm.

Important! The distance at the junction between the bathhouse and the terrace should be within 12-15 mm. The expansion joint can be filled with a suitable elastic sealant and closed with a decorative element of suitable size and configuration.

Useful tips

A bathhouse with an area of 9 square meters is preferable for small areas. It is easy to place it on an already inhabited area. The main rule is distance from flammable objects and wooden buildings. Bushes and trees, on the contrary, will not suffer from such a neighborhood. The adjacent area can be used for planting non-capricious crops that love shading, high humidity and are not afraid of slight temperature changes.

Often they try to increase the usable area of the steam room by abandoning the classic benches. However, you can sit comfortably indoors only if the length of the tier is at least 2.2 meters. A person must fit here at full height. It is quite possible to reduce the width of the bench or its height. The more ledges, the greater the opportunities for bathhouse visitors. Even without a temperature controller, you can find a suitable zone for everyone.

Wooden baths are often imagined as a building made of rounded timber, inside of which the circles of huge logs are clearly visible. However, this option is not very practical in the case of a small area. Such reliefs hide useful space, and visually create a not very pleasant oppressive effect. Therefore, it is better to choose straight lines and finishing materials with a small cross-section.

Building a 3x3 bathhouse is not an easy task. It’s easy to find a place for a building on any site; you don’t have to think about investing in a capital foundation. However, the layout of the interior space and the choice of materials can cause difficulties. A successful bathhouse with a hot steam room, a comfortable relaxation area and a convenient washroom can be built from wood, brick and even expanded clay.