The protection of the insulation layer in the roofing pie is carried out by two types of insulating materials, different in structure and purpose. Their illiterate use, incorrect selection according to technical parameters, and incorrect installation lead to the thermal insulation getting wet and to the loss of the qualities specified by the manufacturer. As a result, instead of reducing heat loss, wet insulation will increase leaks; rooms equipped in this way will be excessively damp and cold.

To avoid the described negative, let’s find out how vapor barrier differs from waterproofing, and how a roof insulation system is constructed using these protective films.

Subtleties of constructing a roofing pie

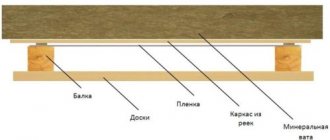

The pie of an insulated roofing system is a multi-layer structure, each component of which must flawlessly perform the work entrusted to it. Its main component is represented by insulation, to protect it from getting wet, insulating films are installed above and below, and ventilation ducts are installed.

The upper and lower protective layers of roofing thermal insulation perform different jobs:

- A barrier laid on top protects the thermal insulation from atmospheric water that falls in the form of liquid precipitation and is formed when snow deposits melt. This layer is called waterproofing; it prevents moisture from penetrating from the outside of the insulation system, but does not prevent moisture from penetrating from the inside from freely leaving the insulation.

- The insulation installed at the bottom protects the insulation from household fumes generated during the operation of the premises, during cooking, hygiene procedures, etc. This is a vapor barrier designed to prevent steam from entering the thermal insulation thickness.

The vapor barrier does not allow vapor to pass through at all or only at a minimum. For its functional purpose, waterproofing must conduct vapor water coming from below. Hence the difference in structure and the differences in the work performed by the materials.

What is the difference between vapor barrier and waterproofing: the difference in technical and technological aspects

Roof insulation

Roof insulation

Steam from water is constantly generated in nature.

Dear friends!

I analyzed this issue through meditation, and in the end this is what was revealed to me. Vapor barrier has two different sides for a very simple reason - due to production technology. In other words, they take a polymer film. A special fibrous (non-woven) material is placed on it. Then, using a large iron, they fuse this film into non-woven material (or vice versa, as you prefer).

As a result, one side turns out smooth, the other remains fleecy. All! The secret is revealed! Nobody made these sides different on purpose. On the contrary, it is simply impossible to make both sides fleecy. Making both sides smooth is apparently possible, but extremely difficult. Apparently you need to turn the canvas over, put another layer of film on it and run the iron over it again (here the question immediately arises - will the film stick to the iron?). As a result, the vapor barrier will more than double in price without significantly improving its performance.

Do you and I need it? Personally, I don't.

Vapor permeability as the main indicator

Vapor permeability is one of the main characteristics of insulating roofing films, which influences the selection and determination of the location for their installation. It is indicated by material manufacturers in the technical documentation, indicated in grams or fractions of a gram, which 1 m2 of roll insulation can carry out per day (mg/m2 per day).

Based on the ability of protective materials to transmit steam, they are divided into two main classes:

- Vapor permeable. Includes all types of waterproofing membranes. The ability to conduct steam amounts to hundreds and even thousands of milligrams.

- Vapor-tight. Includes polypropylene and polyethylene films, anti-condensation membranes. Their ability to pass steam is equal to fractions of a milligram, several units or tens of milligrams.

According to construction regulations, the components of the roofing pie are selected so that their ability to transmit vapors increases from the inside to the outside. Those. The bottom film should have the lowest vapor permeability indicators.

The insulation should be more capable of transmitting steam than the vapor barrier, but it should be less than that of the waterproofing. The described structure of the roofing pie is necessary so that all moisture that may end up in the thickness of the thermal insulation does not linger there and is freely removed outside the roofing system.

In a well-designed pie, everything that managed to break through the vapor barrier barrier rushed through the insulation to the waterproofing, which freely allows steam to pass outside the structure, but prevents raindrops and melt water from penetrating into the thermal insulation.

A similar principle is observed when arranging partitions and ceilings installed between rooms with different operating conditions. Simply put, a thermal insulation system should be installed between the heated rooms and the cold attic, with a vapor barrier deployed towards the housing.

If, within the same floor, a room with standard operating conditions is adjacent, for example, to the steam room of a Russian bath, then a partition between them is insulated by installing a vapor barrier film first from the steam room.

However, for the flawless organization of a roofing system, it is not enough to divide materials into classes according to their ability to prevent or easily release steam. It is imperative to find out what materials are used as under-floor films, what is the difference between the methods of installing vapor barriers and waterproofing, and how the technology for laying them is implemented.

Various uses of waterproofing

When constructing a building, even at the initial stages of the project, you should take into account the place of your residence, or rather the latitude. Indeed, in different parts of the country the temperature varies greatly, but this is not what causes concern, but its rapid changes. In addition, an important factor is the difference in the design features of the roof and the pressure on the waterproofing layer.

Manufacturers of building materials are constantly trying to improve their products in order to create maximum competition and provide something useful to the sales market. It is precisely because of this that today vapor barrier film and waterproofing do not care about either climatic conditions or the design features of the roof.

The quality of different building materials allows it to be used in different conditions. For example, high-quality film can withstand different temperature conditions well.

What is the function of a roof vapor barrier?

- A barrier is created that does not allow moisture to freely enter the thermal insulation layer

- Plays a major role in the ventilation system. It is thanks to it that all excess moisture is removed from the place of formation.

It is worth noting that the pitched roof is the most common and the protection of the rafter system in them is an integral part of construction. If the roofing covering is not installed as a continuous sheet, for example, from tiles, slate or corrugated sheets, then a roofing waterproofing film is suitable.

Vapor barrier protection should be used not only on pitched roofs, but also on any other type of rafter system. Of course, if this object is not residential or is simply temporary, insulation work will be unnecessary. But if the construction cake contains thermal insulation boards, then steam protection will have to be used in any case.

Did you know that even with minimal human activity in the room, for example, when cooking, wet cleaning, washing, moisture vapors already appear that negatively affect the roofing layers? Therefore, think about it and carry out a preventive inspection of your roofing structure to ensure its integrity.

Types of vapor-tight options and their characteristics

Previously, the only vapor barrier option was glassine, which transmits on average about a hundred mg/m² per day. To construct a vapor barrier from it, the roofer needed to show miracles of dexterity, because... the material was easily damaged during installation. There was a problem when connecting glassine strips into a single canvas and when wrapping structures of complex shapes.

Glassine was replaced by polyethylene, and later polypropylene, or more precisely, a film made from it, was introduced into the vapor barrier sphere. They became the basis for the development of an extensive line of polymer membranes used in vapor and waterproofing. The new generation of insulating materials is ahead of its predecessors in strength indicators, resistance to UV and unstable temperatures.

The list of polymer vapor barrier types includes:

- Foil membranes . Materials with a metal shell located on the working side. They are used in the arrangement of hygienic premises that require maintaining the temperature obtained during heating: saunas, steam rooms. The foil surface can serve as a reflector of heat waves if a gap without ventilation is left between it and the casing.

- Anti-condensation films . Rolled materials, one side of which has a rough texture, the other - smooth. A rough surface prevents the formation of dew on the vapor barrier; a smooth surface prevents the reverse flow of moisture that has penetrated or formed in the insulation.

- Films made of polypropylene and polyethylene . Most often these are reinforced analogues of outdated polyethylene and polypropylene options. They are used in budget construction, although at a price per 1 m2 they are not too different from new polymer vapor barrier materials.

Vapor barrier materials with a vapor permeability of several tens of mg per 1 m2 per day are still used to this day in thermal insulation systems for cold attics, insulated with backfill material, for example, expanded clay. If there are real restrictions on the construction budget, then this type can be used in the arrangement of heated attics.

However, the difference between the cost of polyethylene with propylene and membrane barriers is such that there is little point in such savings. In addition, new types of vapor barrier protection are much stronger and are difficult to damage due to careless movements during installation. Anti-condensation membranes last almost as long as roofing coverings, i.e. During the entire operation of the roof, there will be no need to carry out major repairs.

What does the market offer?

Let's look at the most popular options among roofers.

Yutafol: four-layer structure and choice

This company has produced two main types of films as a vapor barrier material:

- Yutafol N 96 Silver, with parameters 96 g/m2.

- Yutafol N 110 Standard, with parameters 110 g/m2.

One of the additional functions of such films is maintaining the optimal temperature of the attic.

Tyvek: quality again

A popular vapor barrier from Tyvek is AirGuard SD5. This is one of the most modern means of protecting roofs from steam. The main advantages of such a film are durability, practicality and environmental friendliness.

Nicobar: for special conditions

This film also has quite high quality. It protects the roofing pie well from steam, and at the same time is not destroyed at all by either ultraviolet radiation or high temperature.

Nikabor film consists of two layers - absorbent and aluminum. Returns some of the heat to the attic and is ideal for arranging a steam room in the attic.

Properties and types of vapor-permeable membranes

The main difference between polymer membranes for waterproofing and materials for vapor barrier is that they freely allow steam and condensation formed in the thickness of the insulation to pass out due to the difference in temperature values under and above the insulation system. A material has not yet been invented that can prevent the appearance of moisture in thermal insulation. However, there are technologies that allow you to get rid of water in the roofing pie, and materials for implementing such schemes.

As already mentioned, waterproofing is placed on top of the insulation. It is located under the roof. Between it and the heat-insulating layer, a ventilation gap is arranged or not, depending on the material used in organizing the system.

Types of vapor-permeable, otherwise called vapor-transparent, materials in demand in construction include:

- Perforated films . Rolled materials with specially shaped holes that allow steam to escape but do not allow water to pass through from the outside. They serve mainly as insulation for slopes above cold attics, because... cannot fully perform waterproofing and windproof functions.

- Porous membranes . Materials with a fibrous structure, similar in structure to a filter. The vapor permeability indicators of this type depend on the pore diameter and the ability of the fibrous fabric to transmit evaporation. This type of waterproofing is not used where there is a possibility of clogging of pores due to excess dust.

- Superdiffusion membranes . The thinnest multilayer membrane systems, each layer of which performs a specific job. There are no holes in their structure that can become clogged with dust, therefore the materials of this group have the highest resistance to all kinds of contamination.

Superdiffuse membrane insulation comes in two and three layers. Two-layer varieties are inferior to three-layer counterparts in terms of strength criteria, because in their structure, one of the reinforcing substrates has been removed. In terms of cost, both options are not too different, therefore, if possible, it is better to choose a three-layer material.

Porous and super-diffusive materials, together with waterproofing duties, play the role of wind protection. They prevent winds from “washing out” heat from lightweight fibrous cotton insulation. Perforated films do not do this job, therefore, when using mineral wool to insulate slopes, they require the installation of an additional windproof carpet, which sometimes reduces the initial savings to zero.

The installation of under-roof waterproofing is necessarily accompanied by the installation of a ventilation system, which can be:

- Single-level . Predetermining the organization of ventilation ducts, vents, between the waterproofing barrier and the roofing. It is installed using superdiffusion and porous membranes, which are not prohibited from coming into close contact with any type of insulation.

- Two-level . Assuming the organization of two levels of ventilation. channels located between the thermal insulation and the hydraulic barrier, then between it and the coating. the scheme is typical when using perforated films

Vents - ventilation ducts located parallel to the pitched roof are installed by installing a wooden batten with a wall height of at least 4 cm. For a two-level system, the river is fixed in two tiers: above the insulation and above the waterproofing. The lathing formed with its help at the same time fixes the roll insulation, and also serves as the basis for laying the roof or continuous flooring for soft types of coverings.

Video of installation of vapor barrier materials

A ventilation gap is left between the coating and the thermal insulation. This eliminates the possibility of moisture retention, which is removed from the room. This rule is mandatory if a diffuse membrane is installed. The superdiffuse analogue does not require such a recommendation due to the large number of pores in the structure. The coating is used to protect roofing insulation from precipitation and steam.

Modern vapor barrier materials are highly durable and, when installed correctly, perform their intended functions well for a long time. At the same time, membrane vapor barrier films can have a stably limited and variable vapor permeability, the value of which is higher, the more moistened the membrane is. That is, with excess humidity, the membrane allows more water vapor to pass through.

In Russia, the undoubted leader in this product segment is the vapor barrier material Izospan with excellent characteristics and a competitive price. Using this example, you can familiarize yourself with this type of protective coating.

Vapor barriers Izospan are produced in the form of a roll material made of polypropylene film 1.4 or 1.6 meters wide and 35 m long. It has a two-layer structure: one side is smooth, the other is matte-rough, which provokes condensation on it and, in the future, its intensive evaporation. Temperature range at which Izospan does not lose its performance characteristics:

- roofs are pitched and flat-pitched;

- external and internal walls (main and frame-panel);

- basement, interfloor and attic floors (floors/ceilings).

The nuances of laying roofing films

We found out that waterproofing materials that protect the cake from atmospheric negativity can be installed with one or two ventilation gaps. They are needed so that moisture does not accumulate in the multi-layer roofing system, but is freely removed by air flow through the vents formed by the slats.

An equivalent function is performed by the ventilation gaps that accompany the laying of vapor barrier films. Regardless of the structure and composition of the material, they are installed with two tiers of ventilation located on both sides of the vapor barrier. Due to low vapor permeability, this layer requires increased ventilation.

Most roofing films do not have the ability to stretch when tensioned. Therefore, they are laid on the rafter frame so that the rolled insulation sag somewhat in the space between the rafters. The sagging is necessary to prevent the material from cracking under tension during standard movements typical of wooden systems.

Waterproofing sheets are laid out depending on the steepness of the structure. On steep roofs, the material is placed along the rafters; on flat roofs, it is placed parallel to the ridge girder. Vapor barrier strips are installed exclusively parallel to the ridge.

The strips are laid with an overlap, the amount of which is indicated by the manufacturer of the insulating products. The side on which the strips should be installed must be indicated on the rolls. Changing sides is strictly prohibited, because As a result, the vapor and water insulation properties will change.

When installing waterproofing, laid parallel to the ridge rib, they start from the eaves line. For proper installation, the edge of the starting waterproofing strip should protrude beyond the edge of the cornice by a minimum of 10 cm. It is then brought out under a drip line or a cornice strip. The strips are laid so that the overlap of the upper panel overlaps the edge of the lower one.

The construction of a vapor barrier begins, starting from the ridge ridge. Each subsequent panel must overlap the edge of the previous one. If you follow the described method in installing both types of insulation, a minimum of water gets into the insulation.

Installation of a vapor barrier layer

The difference in the partial pressure of water vapor during the cold season between the interior of the room and the street leads to an increase in the amount of moisture tending to penetrate through the roofing cake to the outside. To stop this process, a high-quality vapor barrier layer is needed. To create it, dense high-molecular materials characterized by low vapor permeability and sealed fasteners are used.

For high-quality fixation of vapor barrier it is necessary:

- mount sheets or webs of material overlapping. The overlap of adjacent fragments must be at least 10 cm;

- To fasten the coatings, use special nails or self-tapping screws with a rubberized head, ensuring tight contact when twisting or driving in. It is possible to use a construction stapler, the staples of which minimally deform the material and seal the penetration site;

- when installing combined materials (polymer with reflective aluminum foil or non-woven geotextile), the smooth side of the polymer layer should be facing the insulation;

- It is necessary to leave a gap between the vapor barrier and thermal insulation coating to ensure ventilation and prevent moisture accumulation.

Video: Condensation on the roof + incorrect vapor barrier.

Why is insulation needed?

Insulation is required in order to protect the building from the negative effects of precipitation. Currently, you can find a huge number of film coatings on the market. When choosing, you should be careful, since the wrong insulation material can cause the roof to leak. But the situation can only be corrected in the warm season, since you will have to dismantle the roof and re-lay all the layers.

In order to make the right choice of material, it is worth understanding what is the difference between vapor barrier and waterproofing. These materials are completely different; they differ not only in appearance, but also in properties.

The waterproofing layer protects the insulation, preventing moisture from outside from affecting it. Otherwise, the performance properties of the latter will be greatly reduced.

Naturally, warm steam rises to the ceiling, trying to penetrate the insulation. If this happens, the likelihood of mold and dampness growing inside the house increases. And this has a destructive effect on the structure of the building and interior decoration. To prevent this from happening, a vapor barrier is created from the inside.

Vapor barrier films – 100% protection against steam penetration

Such products have a 100% waterproof surface on both sides that does not allow steam to pass through or release it.

The most affordable option is simple plastic film, which is usually used by summer residents in their gardens. True, it can only be used for roofing as a last resort, since there is always a high temperature under the roof, under the influence of which the multilayer film can lose its properties. The best option is to use a multilayer film with a reinforcing polymer frame.

Vapor barrier films

The presence of a frame will not allow the vapor barrier material to stretch, and many layers of film will ensure the longest possible service life.

But the best and at the same time the most expensive type of material for roof vapor barrier can be called foil film. The foil part is laid inside the roof, which will reflect infrared radiation. This film will protect the insulation from steam penetration and increase the level of warm air retention, and you will save on heating in the winter.