In the age of modern technology, when most building materials are one or another petroleum products, traditional technologies for constructing housing using environmentally friendly raw materials are coming back into fashion. One of these design solutions, which, unlike innovative coatings, does not have a negative impact on human health, is considered to be a plank roof. A roof made of natural wood has a rich history of use and assembly technology that has been refined over centuries, so it reliably protects the house from the penetration of precipitation without interfering with its ability to “breathe.” In this article we will talk about the features of the design and assembly of a roof made of yew, that is, edged boards.

What is a plank roof?

When cutting logs longitudinally, edged boards of the same thickness along the entire length are obtained.

The edges of the boards are trimmed to make the material more uniform and easier to lay. This kind of lumber is called plank. The plank roof is made up of such boards laid in 1 or 2 layers. The design of the roof is very simple, its installation does not require much effort or special skills. At the same time, the appearance of the roof is very attractive. This option is ideal for buildings built in a rustic style, in a country style, in a chalet or in a hunting house. Even more often, this option is used in the construction of outbuildings.

Wood is a very beautiful, lightweight material with excellent thermal insulation properties. However, the tree does not withstand the effects of rain, snow and sun as well as we would like. A plank roof requires periodic and relatively frequent repairs, as well as maintenance - the boards should be treated with antiseptics or painted. On the other hand, repairs with such a roof arrangement are easy to carry out: at any time you can replace cracked or fungus-affected boards with new ones.

The board roof looks original and unusual. However, it is better to use such material for log buildings made of timber or wooden bricks.

Design

Houses with this type of roof stand out from the rest. The design of the plank roof is aimed at recreating the Russian rustic style, or the structure of hunting lodges. A plank roof looks best on buildings made of timber.

Beautiful plank roof design Source homebuilding.ru

The use of a plank roof will make the building stand out from other houses, giving it uniqueness. Installing a plank roof is the best solution for those who are looking for a non-standard opportunity to decorate their own home.

For a plank roof, exclusively pine is used - this is a priority tree due to its characteristics. It perfectly insulates the house, but requires constant maintenance. According to experts, arguing that the plank roof is a reliable material, there is no reason to doubt it. But due to temperature changes, exposure to rain and sun, it will worsen its condition. Therefore, the roof must be regularly treated with antiseptics, or constantly painted. But repairing a plank roof is not difficult; the boards can be easily removed. In order to replace one board, you do not have to dismantle the entire roof.

Design

In the old days, plank was the name given to processed wood, that is, edged board. To obtain a plank for constructing a roof, the log was cut longitudinally, and then the edges were trimmed so that the board had the same width along its entire length. Previously, this work was done manually, but now lumber is obtained using automatic equipment, setting the required thickness of the element. The edged board was laid on the rafters in 2 rows, so that atmospheric moisture did not pass through it. In order for a shingle roof to last longer, the wood must be properly prepared:

- First, the lumber is planed using a plane to make the surface of the wood smooth, making further processing easier.

- Then the board is impregnated with antiseptic preparations necessary to protect the wood from the effects of mold and fungal microorganisms that lead to rotting of the material in conditions of high humidity.

- At the final stage, the edged board is impregnated several times with a fire retardant substance to reduce the risk of a fire occurring and quickly starting.

Note! Timber roofing is made from high-density hardwood. Pine is considered a more affordable material in terms of cost, but larch, which contains natural phytoncides and essential oils that prevent wood decay, is much more suitable for constructing a roof.

Frame for the construction of a wooden roof

A short excursion into history

Wood has been used as a roofing material for a long time. Traditionally, such roofs were in regions with a cool climate, significant reserves of valuable wood and a lack of raw materials for the manufacture of other types of roofs: slate and ceramic. These are central and northern Rus', Scandinavia, northern Germany, Belgium, the Baltic countries. Many peoples of Siberia also built houses under shingle roofs. Russian architects achieved the highest perfection in the construction of roofs covered with wood. The skill of our ancestors, who delicately covered zakomaras, kokoshniks, domes of churches and royal chambers with figured plates, is unsurpassed.

The kokoshniks, drums and domes of the Church of the Transfiguration of the Lord are covered with carved pine plates. Although they have a similar shape, they have different sizes

The first settlers of the North American colonies used wood chips not only as roofing material, but also sheathed their entire houses with it. The vast majority of pitched roofs in the northern states of the United States and throughout Canada were covered with wood until the mid-twentieth century. A modern high-tech (and inexpensive) roofing material invented by the Americans - bitumen shingles - imitates wood shingles in shape. Moreover, unlike Europe and Russia, where in the mid-twentieth century the shingle roof lost its relevance, in North America the tradition was not interrupted, the production of roofing materials from wood did not stop, and technology was constantly being improved.

Americans love wood shingles and know how to work with them. In this case, several die formats were used

Advantages

A roof made of edged boards, which is impregnated with an antiseptic and fire retardant, is considered a real alternative to modern roofing technologies. High requirements for environmental safety of building materials and health concerns are forcing people to return to traditional methods of housing construction instead of using coatings based on bitumen, asbestos and other hazardous substances. The advantages of plank roofing are:

- Low thermal conductivity. Wood has a low thermal conductivity coefficient, so the roof does not heat up from the sun and does not release heat during the cold season.

- Breathability. Wood allows steam and air to pass through, so a house with a roof made of this material “breathes” and creates a healing microclimate that is pleasant for living.

- High noise-absorbing ability. Edged board roofing effectively dampens sounds during rain or wind.

- Unusual design. Structures with plank roofs look original; they repeat the appearance of a traditional Russian tower.

Important! The main advantage of the technology for constructing a roof from edged boards can be called environmental safety. All materials and fasteners are safe for human health and nature. In addition, its assembly does not require complex tools and skills.

Advantages and disadvantages of plank roofing

A plank roof has many advantages. They are connected both with the material and with the laying technology:

- wood has the highest thermal insulation qualities among all natural building materials - a roof made of edged boards guarantees warmth in winter and coolness in summer;

- wood has unique properties for regulating the microclimate - when the air humidity inside the room is high, the tree absorbs moisture and releases it outside, but if the humidity inside the building drops, the tree replenishes it, thereby ensuring a healthy microclimate; a plank roof fully possesses this advantage;

- tes have excellent soundproofing qualities: such a roof dampens the noise of rain, wind and hail;

- wood is a 100% environmentally friendly material and does not pose any danger to the environment;

- the cost of a plank roof is minimal: edged boards, even from relatively expensive species, are the most affordable material for roofing;

- the roof is lightweight even with large dimensions, therefore, installation of the roof does not take much time, and the roof itself does not place a large load on the foundation;

- the interesting appearance is also an important advantage - after a while the boards darken, and the wooden building with a plank roof takes on a magnificent authentic look.

Unfortunately, wood has disadvantages:

- the material is a fire hazard, the boards are treated with fire retardants before laying, but this only reduces the ability to ignite, but does not exclude spontaneous combustion of the tree;

- lumber needs protection from mold, fungi, and bark beetles; lumber is treated not only before installation, but every 3–4 years of operation;

- wood is prone to shrinkage, in the first years the board shrinks by 10%, no less, this factor must be taken into account when laying boards;

- Roof repairs will have to be carried out every 4–5 years.

Roof maintenance is simple and does not require special knowledge. The responsibility to monitor the integrity of the planks and replace deformed boards will not burden the owner of the building too much.

Flaws

On the other hand, it is difficult for plank roofing to compete with modern roofing materials, which are characterized by a long service life, aesthetic appearance and ease of operation. Despite its widespread use in ancient times, roofs made from edged boards have disadvantages:

- Heavy weight. Compared to modern roofing materials, a plank roof weighs a lot, which is why it is necessary to strengthen the rafter frame, which increases the cost of time and expensive material.

- Fire hazard. Wood is a flammable building material, so it must be deeply impregnated with a fire retardant to reduce the risk of fires occurring and quickly spreading.

- Difficult to care for. In order for a roof made of edged boards to last long enough, it must be periodically treated with moisture-repellent and antiseptic agents, otherwise it will begin to rot.

Please note that high-quality wood, especially larch, is quite expensive, so this technology can hardly be called economical. If you use low-quality boards for roofing, it will last a long time.

Board roof

Briefly about the main thing

A plank roof is an excellent material that is easy to install. There is no need to have professional skills to learn how to attach a plank roof yourself.

A board roof is perfect for people who are ready to monitor the condition of their home and periodically treat it. With proper care, it will serve its owner faithfully, delighting him with the warmth of his own home.

For those who are looking for a material that needs to be installed once and for all, without putting their hands on it, installing a plank roof is not suitable. Even if minimal damage occurs, the plank roof must be treated as quickly as possible. Also, in case of rotting, it is necessary to immediately replace the boards. Removing the board is not difficult; there is no need to go through the entire roof.

A plank roof is easily flammable and catches fire, so it is not recommended for use in areas with a high temperature climate.

In terms of cost, a plank roof is a budget option, but when using high-quality wood, such as larch and cedar, the cost of installing a plank roof increases significantly.

Ratings 0

Timber roof material

Edged boards for a plank roof should be selected taking into account certain characteristics.

For a plank roof, boards made of coniferous wood are required. Such wood contains more resin, and the latter protects the material from moisture:

- the most affordable option is pine boards; pine boards do not warp, are resistant to fungus, but require periodic treatment with antimicrobial compounds, as they are prone to rotting;

- In terms of user characteristics, spruce is close to pine, but is more resistant to moisture;

- cedar is very beautiful, this material is more expensive, but it has bactericidal properties and is very durable;

- the best material for a roof is larch, this tree is not at all afraid of rain, snow, or sun, and over time it only becomes harder and stronger, larch boards have virtually no knots or stains, are very beautiful and last an exceptionally long time, but the wood is made of larch is the most expensive.

We recommend reading: Roof drip line: types, purpose, installation rules

Technical characteristics of planks must also meet certain parameters:

- boards for plank roofing should be made only from the driest wood, this causes shrinkage of the material, but guarantees greater durability;

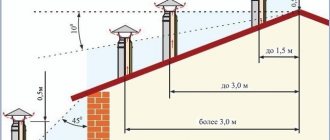

- the board must correspond to the length of the slope, and it should be taken into account that the slope of the plank roof must have a slope of at least 28 degrees to ensure water drainage; boards are produced with a length of 4 to 6.5 m;

- the thickness of the edged board ranges from 1.9 to 4.0 cm, the width of the board ranges from 16 to 25 cm; It is not recommended to use lumber with a width of more than 20 cm, as it is more prone to warping and drying out under the sun;

- on one side of the boards, a groove is made along the entire length: this ensures water drainage, it should be taken into account that when laying in layers, the planks are alternated: the lower boards are fixed with the core down, and the upper ones with the core up, the photo shows a plank roof;

- the boards must be planed on 4 sides, this is very important, since boards planed on only 3 sides are much less susceptible to treatment with fire retardants and fungicides, which significantly affects their quality.

Important! To waterproof a plank roof, you should not use roofing felt or ordinary polyethylene film.

To prevent condensation, you will have to install the roof so that there is a ventilation gap between the board and the film. In order not to complicate the design, it is better to use new waterproofing materials that allow steam to pass through from the inside of the attic.

Large explanatory dictionary

TOS,

-a (-y);

m. collected

Thin boards (hewn or sawn).

Fresh, new t. Cover, cover, sheathe. Tesovy, oh, oh.

T-th gate (made of planks).

T-th roof, veranda

(timbered).

TESAK, -a; m.

1. Cutting and piercing edged weapons with a wide and short double-edged blade on a cross-shaped handle.

Wide, straight t. Wear t. on the belt. Hit with a cleaver.

2. Carpenter's ax for cutting wood.

Cleaver, oh, oh. CUT see CUT.

CHOEWED, oh, oh.

Worked or hewn. T. granite. T. timber, stone. T-th wall. T-slabs.

TEST, amuse, amuse;

hewn; -san, -a, -o; nsv.

1.

(what).

By chopping lengthwise, remove the surface layer (from wood, stone, etc.).

T. logs, stones, pieces of wood. T. with an axe.

2.

what.

Made from wood, stone, processed with an axe.

T. shovels, pegs. Oars hewn from solid logs.

◊ At least a stake on

someone’s head.

About a very stubborn or slow-witted person.

To tease, to tease; suffering

Hewing, -i;

Wed

Teska, -i;

and. T. saw teeth. Suspend T. T. granite.

CLASH

see Cleaver.

Ribbon, -i;

pl.

genus. -mok,

dat.

-mkam;

and.

1.

Unlock

A narrow woven or braided ribbon used for lining, decoration, or fastening something;

braid. Colored, bright t. Trim the collar with ribbon. Sew a silk ribbon onto the dress.

2. A tie made from such a ribbon.

T. folders. T. on the robe. Tie, untie, break the ribbons.

Ribbon, -and;

pl.

genus. -check,

date.

-chkam;

and. Decrease-affectionate I bought such a pretty ribbon! Too inconvenient ribbons.

Ribbed

(see).

Ribbon, oh, oh.

to Ribbon. T-th production. T loops. T. belt.

Ribbon, oh, oh.

Razg.

Made from braid, ribbon.

T-th decorations. T-th lacing on the dress.

TESINA, -s;

and.

One plank.

Wall, fence made of ties.

TESKA

see Hew.

TESLO, -a;

pl.

adze, -sel, -slam;

Wed

A carpenter's tool, a type of ax with a blade located perpendicular to the axe.

Bocharnoye t. Hammer with an adze.

CLOSE

see Tight.

TESNINA, -s;

and.

A narrow, deep river valley with steep slopes.

Foggy T. * In the deep gorge of Daryala

(Lermontov).

// A narrow passage between mountains and cliffs. Dangerous, rocky t. The narrows of life

(about a very difficult situation).

CRUSH, -nu, -nish; nsv. someone or something

1. Moving close, push, force to move away, move away somewhere.

T. to the wall, to the cliff, to the fence. T. in the corner, on the seat. T. from the table. Passengers crowd each other. T. crowd, troops, enemy

(to force to retreat).

2. To make the space occupied by something too narrow, cramped, depriving it of spaciousness. Mountains crowd the river. Trees crowd each other.

3.

only 3 l.

Fitting too tightly, pressing, pressing, causing discomfort, pain (about tight clothes, shoes).

The jacket is tight on the shoulders. The dress is tight in the chest. Shoes are tight on your feet.

□

no. I can’t lift my arm in my jacket—it’s starting to feel tight under my armpit. The leg feels tight in the instep.

4.

(St.

to embarrass).

To twist, squeeze (throat, chest, breathing) from a strong feeling, pain, fear, etc. Excitement takes your breath away. Sobs constrict my chest.

// Cause a feeling of painful pressure, compression in the heart, in the chest.

Melancholy presses in my chest.

□

no. It feels tight in the pit of my stomach. It feels tight in the chest. The heart is tight.

5. Cause a feeling of heaviness in the chest.

I am overcome with gloomy forebodings.

6. Deprive of advantageous positions and advantages.

Cooperatives are crowding out state-owned enterprises. Professionals are crowding out amateurs.

It's crowding, it's crowding;

suffering (1-2, 6 digits).

Timber roofing technology

The roof structure is really very simple. But here, too, there are a number of features that need to be taken into account so that the roof lasts a long time and does not need annual repairs.

The first of these requirements is the mandatory treatment of boards with fire retardants and fungicides. Otherwise, the roof will not last long.

Laying methods

There are several ways to lay the board. The choice depends on the purpose of the building - residential building, outbuilding, as well as on the weather conditions of the region:

- the simplest option is to lay the boards in one layer close to each other, the gaps between the boards are closed with strips - wooden slats measuring 20 * 50 mm;

- A two-layer roof is more reliable; the boards are also laid close to each other, but in the second layer the center of each element falls on the joint between the planks in the first layer - this prevents the plank roof from leaking;

- The laying order may be different, in order to reduce material consumption, proceed as follows: in the first layer, the boards are fixed at a distance of 5 cm from each other, and in the second layer, the upper boards cover these gaps;

- transverse laying - in this case, the boards are placed not along, but across the slope, the planks are laid with an overlap: first, the lower element is secured, and each subsequent one is laid with an overlap of 5 cm.

The roof can be not only two, but also three- and even four-layer. In this case, the displacement is reduced: with a three-layer installation, each next row is fastened with an offset of 2/3 of the length, with a four-layer installation - with an offset of ¾.

Laying technology

Board roofs are a fairly simple design. The construction of such a roof requires accuracy rather than skill.

- It is necessary to calculate the required amount of material taking into account the chosen installation method. To do this, first determine the number of boards in a row - divide the width of the slope by the width of the board, then the number of rows - divide the length of the slope by the length of the board. By multiplying the obtained values, we obtain the Tesa number for row 1. If the laying is two-layer end-to-end, the quantity is multiplied by 2 and increased by 10% in order to take into account defects or damage during operation.

- A waterproofing film, preferably a vapor barrier, is fixed to the rafters.

- A lathing of 50*50 mm wooden beams is installed on top of the film. The slats are laid across the slope if longitudinal laying is intended. The sheathing provides a ventilation gap between the waterproofing and the board.

- The plank board is laid according to the chosen method and secured with self-tapping screws in increments of 50–60 cm. Then a second layer is installed, and a third if required.

- After laying the board, the ridge is waterproofed with roofing felt, a ridge board is attached, and a steel corner is installed on top for protection.

Transverse masonry does not require the installation of sheathing, since the rafter system itself acts as a completely suitable base. However, in this case, waterproofing can only be done with a vapor barrier membrane.

Types of wood for roofing

Rocks that contain natural preservatives: resinous or tannins are suitable for roofing work. They significantly increase the service life of the material. Almost all conifers contain resin; budget options include pine and spruce, and in Western Europe, fir. Aspen is accessible, easy to process, but does not last long. Siberian larch and Canadian red cedar have the maximum amount of resin (correspondingly, the highest service life).

In Germany, where there are more oak forests than coniferous forests, oak or beech plates were traditionally used on the roof. Exotic species are also used as shingles: teak, ebony, rosewood. They are beautiful and durable, but few people can afford them. There is a beautiful and original shingle made from tree bark, usually oak.

Particularly popular are shingles made from Canadian cedar, aspen, oak, and Siberian larch.

Features of shingle roof care

Caring for a wooden roof is quite simple and comes down to timely inspection and elimination of defects:

- in the spring, the roof is cleared of snow before it begins to melt, otherwise the risk of roof leakage and excessive swelling of the wood increases;

- defects discovered during inspection should be eliminated immediately, cracks and chips should be sealed with putty; if the roof is painted, then the putty is first mixed with the same paint, and after drying, it is also painted;

- if the plank roof was covered with bitumen, the cracks are treated with a mixture of bitumen and chalk;

- Once every 3–4 years it is necessary to treat the wood with fire retardants and fungicides;

- If rotten boards are found during inspection, they should be replaced immediately.

We recommend reading: Metal rafters: pros and cons, application, types

Important! A plank roof can last up to 15 years with proper use and timely maintenance.

What kind of lumber should be used for roof rafters?

There are serious requirements for the quality of lumber for roofing. This is especially true for wood used to create rafters. The most suitable types of wood for the rafter system are coniferous and deciduous. Such lumber must exactly comply with the requirements of GOST 2695-83 and GOST 8486-86 . The board for the roof of a residential building must have a minimum cross-section of 50x150mm. This applies to lumber up to 6 meters in size. The board for rafter legs has the following requirements:

- There should be no more than three knots per linear meter. The maximum knot diameter is 30mm.

- Non-through cracks, no more than half the length of the board.

- Humidity should be no more than 18%.

You should not choose rafter boards with high humidity levels. The rafter system will be fragile, and this, in turn, will be unsafe for the people living in the building. After a short period of time, the geometry of the entire structure can be disrupted due to wet rafter boards.

Advantages of a wooden roof made from edged boards

- Wood is an environmentally friendly product with low thermal conductivity. As a result, the rooms will not be heated by the sun's rays in the summer, and in winter they will be better able to retain heat.

- The plank covering absorbs the noise of rain and wind.

- Laying such a roof requires less labor.

- The cost of a wooden plank roof is lower than other roofing options.

- Caring for such a roof does not require special skills.

- The building with a wooden roof looks unusual and original.

At the same time, plank roofs have a number of disadvantages:

- the structure is quite heavy compared to other roofing options, especially when laying planks in two layers;

- due to the fire hazard of lumber, deep treatment with fire retardants is required, which must be repeated every five years;

- the tree is susceptible to atmospheric influences, as well as to bark beetles, so constant additional treatment with bioprotection and paint is required.

Which is better: splitting, peeling or sawing?

Classic methods of producing wood roofing materials involve finishing it without sawing. The parts are split or peeled. For splitting, relatively dry workpieces are used; the thickness of the plates is quite large - 6-18 mm. The peeling method produces thin plates up to 5 mm thick. The planks are also split and then hewn with a plane. In all of these cases, the structure of the wood is not damaged, the natural pores remain closed, and the roof does not actually get wet. When sawing, the saw teeth break the fibers, opening air voids for moisture to penetrate. Sawn wood will absorb ten times more water and will quickly break.

The classic version of shingle tattooing

In order for a tree to split into ideal dies, it must have a homogeneous structure with a straight (radial) arrangement of layers. The core part of the trunk is used; the core and sapwood are unsuitable due to their lower density. The best effect comes from the butt part: fewer knots. Mature trees with a trunk diameter of 40 cm or more are used.

Handcrafting wood roof components is very difficult. There are a number of devices that make work easier: vices, blades and special axes, beaters, hand tools. Now, when labor done by hand is expensive, equipment has emerged that makes it possible to mechanize a decent part of production processes. Americans are considered the favorites in this area.

Selection of material and procedure for laying the roof

The board roof is assembled from edged lumber from 19 to 25 mm. In this case, the best width of the board is 150–200 mm.

Experts do not recommend using lumber wider than 200 mm, because the tree is susceptible to warping and, under the influence of sun, rain and snow, a wide board can “lead”, even cracking.

On one side of the board, longitudinal paths are made in the form of grooves along which water will flow. It should be taken into account that the lower boards are laid with the core down, and the upper ones - with the core up. This increases the resistance of wood to external influences.

When calculating the length of lumber, it must be taken into account that the plank roof is installed with a slope of no less than 28 degrees. The largest angle for the slope of such a roof is considered to be 45 degrees.

When planning the roof structure, you need to remember that it is not recommended to lay roofing felt or other waterproofing materials directly under the roofing planks.

An under-roofing layer made of such material must be laid while maintaining a ventilation space between the film and the board of at least 50 mm. For these purposes, today builders use modern hydro-vapor barrier films, in which the top layer does not allow water to pass through, and the inner layer, from the attic side, allows steam to pass through, which, condensing into moisture on the top layer, flows down the film to the ground.

Features of a flat roof in a private house: roofing options

When it comes to flat roofs, many people immediately imagine high-rise buildings in the city. Actually this is not true. A flat roof is perfect for a private home if it snows infrequently and the wind is very strong. The remaining snow will be easily blown away by the wind. The main advantage of such a roof is that the strongest wind will not be able to blow it down. In addition, you can build a small greenhouse or garden above it.

A flat roof in a private home has many advantages. The undeniable advantages of this design are that:

- it takes up much less space than a conventional roof, this will help you spend less money on construction;

- it is erected faster than a pitched one;

- it is safe to build such a roof, since it is almost impossible to fall from it;

- the roof is easy to repair;

- the new roof covering is laid directly on the old one, which significantly saves time and serves as additional insulation and protection;

- the roof can be used to build a small building (garden, greenhouse or terrace);

- the roof can be made transparent and you can enjoy a beautiful view at night;

- the building can be done in a minimalist style, it will look simple and fashionable.

The main disadvantage of a flat surface is that in winter it becomes clogged with snow. If there is a lot of snow, the roof will have to be cleaned manually, and this can lead to damage to its coating. In addition, this design has other disadvantages:

- the roof structure is more complex, it requires channels for water drainage, which can become clogged and require additional maintenance;

- Unlike the usual top, from which water flows quickly, on a flat roof the water will stagnate, so you need to constantly check that the insulation is not excessively wet;

- Although you need few building materials, building such a shelter will be much more difficult, since you need to know many additional features.

Due to a considerable number of shortcomings, many people have doubts about building such a roof. But there are many similar houses in European countries with successful experience, so there is no doubt and start building a home.

It is important to take into account that there is more snow in our countries than in European countries. In addition, the difference in summer and winter temperatures is very large

Not all building materials can withstand such temperature changes.

Appearance and coating options

Before constructing a flat roof, you need to stock up on the necessary materials. To erect the frame of the building you should take:

- reinforced steel sheets;

- sandwich panels intended for shelter;

- reinforced concrete slabs.

If the coating can be made with ventilation, then moisture insulation can be used without ventilation at all, such as, for example, roofing felt. The structure, which is considered flat, actually has a slight slope towards the rainwater drainage pipe.

There are 2 options for a flat roof - used (inversion) and unused. The most inexpensive would be a building with an unused top, but to build an inversion one you need a lot of extra building materials.

A special roof option is inversion. This is an option in which a garden, greenhouse or terrace can be built on the surface of the building so that you can walk. This will put a lot of stress on the structure, so it must be further strengthened. An important difference between these types is that in the first version the thermal insulation is located under the water insulation, and in the second it’s the other way around. But at the same time, the second option is quite durable, so you can safely build a greenhouse or even a cafe.

Installation of an unused roof

Despite the differences described above, it is also sometimes possible to climb onto an unused roof (for example, to repair or clean the covering). In the usual version, there is protection from moisture on top, which is affected by weight or temperature changes. There is a special construction option - with a pressure layer. It withstands infrequent human visits well.

Characteristics of the structure being used

Typically, such a structure is inclined by five or seven percent. This method is designed to place heat insulation on top of the moisture barrier, which in this embodiment acts as a steam protection.

The structure of the roof in use can vary greatly. It is influenced by the structure you want to place on the roof. Only the base will be the same. It consists of a monolithic covering that will make the area level. After this, moisture protection is installed, and the whole thing is covered with insulation on top. At the very top there is a mixture of sand and cement or a layer of rubber.

Options for laying a plank roof

Roofing from edged lumber is assembled in several ways.

- Longitudinal laying.

- The board is laid in one layer. In this case, the roofing material is laid close to each other. The joints at the top are covered with flashings. This is the name of a wooden plank 20x50 mm.

- The plank covering is laid in two layers. In one embodiment, the bottom layer is laid end to end, and the boards on top are folded in the middle onto the joining gap of the bottom row, protecting the roof from leaking.

In another, the boards below are mounted at a distance of 50 mm from each other, and the upper lumber covers these gaps. This is done to save material and facilitate the design.

- Cross laying. The plank is assembled across the slope. In this case, the bottom board is laid first, then the next roofing element is laid with an overlap of 50 mm. And in this way the entire roof is assembled up to the ridge.

Laying methods

To obtain a sealed coating protected from moisture penetration, the boards are laid on lathing attached to the rafter legs. There are several ways to lay the board:

- Single layer.

This technology involves laying the board in one continuous layer without gaps. The seams between the boards are sealed with slats measuring 20x50 mm, which are called flashings. Single-layer and double-layer installation - Double layer. This roof consists of two layers of boards. The first is laid on the sheathing side by side, and the second is laid on it with an offset of half the board so that the seams between the elements overlap with the planks of the next layer. To save material, you can lay the first layer with a gap, and with the second one close these distances between the boards.

Two-layer laying with intervals

Two-layer laying offset by half a board - Transverse. In this case, I mount the board across the slope. The bottom board is laid first along the roof overhang, and then the second element of the plank roof is fixed onto it with an overlap of 50 mm.

Cross laying

Example of cross laying

Please note that the roof made of planks, in order not to allow atmospheric moisture to pass through, must have a slope of 28-45 degrees. In this case, the bottom layer is laid with the core down, and the subsequent ones, on the contrary, with the core up.

The procedure for installing a roof covering made of planks

In addition to planks, to lay a wooden roof you need to prepare the following materials:

- block for lathing measuring 50x50 mm;

- ridge board, it is necessary to cover the ridge;

- metal ridge cap to protect the seam between the ridge boards from leaking;

- strip of roofing felt for ridge boards;

- water vapor barrier film.

- The first step is to lay out a water vapor barrier film on the rafters, which is attached to them with a stapler, and then a block is laid along the joists.

- On top of the film, across the slope, a sheathing is mounted on the block with a pitch of no more than 600 mm.

- The plank board is laid according to the chosen option on the sheathing and secured with self-tapping screws. The use of self-tapping screws makes it easier to disassemble the roof, if necessary, and also reliably fastens the plank to the sheathing. Nails, if the boards bend from drying out, may not hold the board.

- A strip of roofing material is laid on the ridge, on top of which a ridge board is attached on both sides of the roof. A protective steel corner is placed on top of the ridge board.

A plank roof is a good choice when building a country house or any utility room on the site. It has an unusual design that attracts attention, and at the same time ensures environmental cleanliness indoors. Do not forget that the price of such a roof is much more profitable than other possible options. Watch the video on the topic:

Installation

Installation of plank roofs can be carried out both transversely and longitudinally. Longitudinal masonry is considered the most practical and therefore more common than transverse masonry.

In general, the installation scheme looks like this:

- the sheathing is installed, wooden beams 50*50 are suitable for this;

- then the first layer of the first row is attached end-to-end; to fix the planks, nails are used, driven in increments of 50-60 cm;

- The same principle is used for laying subsequent rows of slopes;

- Next, the second row of wooden roofing is installed in such a way that the lumber overlaps the joints of the underlying layer - that is, the material is applied in a checkerboard pattern.

It is important to remember that the cores of the annual wood rings in the first row must be located up, and in the second - down. This allows for maximum structural density.

At the final stage, the cornice is hemmed with a board, for example, clapboard.

We recommend reading: Sunroof, how to install a sunroof with your own hands - step-by-step instructions

Transverse masonry is in most cases used for temporary buildings, so the stage of forming the sheathing is skipped. This method of masonry assumes that the boards of the upper row overlap the planks of the lower layer by several centimeters, and each intersection is also fixed with nails.

See below for the structure and visual process of installing a plank roof.

The main stages of laying a plank roof

- A hydro-vapor barrier film is laid on the rafters, fixing it with a stapler to the staples.

- Between the roofing insulation it is necessary to provide a ventilation gap of at least 5 cm. Therefore, bars are installed along the joists onto which the sheathing is placed.

- The sheathing elements are secured, maintaining a distance of no more than 60 cm between them.

- Installation of the board is carried out according to one of the above installation options. The use of self-tapping screws for fixing the boards, on the one hand, ensures fastening strength, and on the other hand, if necessary, facilitates disassembling the roof. Ordinary nails are not suitable for such purposes, since if the roof begins to deform, the fasteners may not be able to cope with this load.

- Upon completion of installation work, the roofing cornice is hemmed.

Construction of the rafter frame

The rafter system is the basis of the roof, its skeleton, which gives it the necessary shape, rigidity, and allows it to withstand and distribute significant loads. When installing cone-shaped roofs, the layered type of frame is most often used.

In this case, the rafter legs rest with one end on the mauerlat placed on the upper chord of the wall, and with the other end on the stand, a vertical support. The rafter frame of cone-shaped roofs consists of the following elements:

- Mauerlat. In the place where the rafter frame will be installed, a ring-shaped Mauerlat is laid, which will evenly distribute the weight of the roof. For this purpose, rafters are attached to the mauerlat or support beam along the perimeter of the semicircular wall in the lower part of the rafter frame.

- Ties. Additional strength is given to the structural unit using ties. To do this, install a cross that pulls together the opposite sides of the Mauerlat.

- Rack. A vertical post is installed in the center of the cross, into which the upper parts of the rafters are cut.

- Rafters. The rafters, with their part, which ensures the strength of the fastening, are connected at the top point of the roof, forming a ridge unit. And with the lower part of the leg they are attached to the Mauerlat.

- Lathing. The sheathing is fixed perpendicular to the rafter legs. Make it from slats or something else and screw it to the rafters with self-tapping screws. The choice of pitch between slats is explained by the choice of material and the required distance for its fastening.

Self-supporting roof

Calculation of material for covering a cone-shaped roof

Timber roof care

- In the spring, even before the snow begins to actively melt, it is recommended to completely clear the roof of snow.

- Any defects, even the smallest ones, identified on the covering during a roof inspection must be repaired immediately.

- Small defects on a painted roof are repaired with a special putty to which a little paint is added. After the putty has dried, the repaired area is painted over.

- To seal defects on plank roofs covered with bitumen, you need to putty them with a mixture of chalk and bitumen. The area with dried putty is covered with a patch, which is glued to hot bitumen.

Choosing a shingle roofing material

For the construction of a plank roof, edged lumber from 19 to 25 millimeters is used. The optimal width of the edged board is 150 – 200 millimeters.

Experts advise not to use material more than 200 millimeters wide, since the wood is subject to warping under the influence of rain, snow and sunlight.

On one side of the board, longitudinal tracks are made in the shape of grooves. Water will flow down them in the future. It should be noted that the upper boards are mounted with the core up, and the lower ones - with the core down. In this case, the tree becomes more resistant to various external influences.

The slope of a plank roof must be at least 28 degrees. This should be taken into account when calculating the length of the material. The maximum slope angle of the plank roof slopes is 45 degrees.

When planning the roof structure, it should be remembered that it is not advisable to lay roofing felt and other materials for waterproofing directly under the planked roofing boards.

When laying an under-roofing layer made of such material, it is necessary to provide a ventilation space between the board and the film of at least 50 millimeters.

Today, water vapor barrier films are used in construction for these purposes. The top layer of such films does not allow moisture to pass through, and the inner layer, facing the attic, allows steam to pass through. On the top layer, steam condenses into moisture and then flows down the film.

Overview of species

There are several types of plank boards, with specific features of their use in construction work. First of all, planks are divided into edged and unedged.

Edged

It is easy to distinguish: edged veneer has a rectangular cross-section, the edges of this board are always carefully sawn perpendicular to the faces, and there are a small number of defects. There is an option when the board is cut only on one side. Made from wood such as spruce and pine. Lumber is very popular and is chosen more often, unlike unedged timber.

Edged blanks are used to decorate and decorate premises. Thus, this option is ideal for finishing construction. The material, made directly from solid wood itself, is very durable and resistant to fungi.

There is a wide selection of edged boards - there are different cross-sectional sizes, allowing you to select a building material that is exactly suitable for the construction in which it will be used. The standard ratio is as follows: double the thickness is less than the width. For example, plank boards 25x150x4m and 25x100x6m are common.

Unedged

Such wooden building material is produced with wane, and it has also found its place for solving various problems, including the construction of temporary huts. The edges are either left unsawed or not completely sawn. The cut can be radial or combined.

The wood has the same strength properties as edged veneer. The unedged type is used in rough work. Suitable for formwork, it also makes reliable scaffolding at construction sites.

Builders purchase such a plank, and then process it with tools themselves, thus obtaining an edged board for a lower price. This is a joiner's unedged plank, which is one of two existing types. Another unedged lumber is called fence lumber.

Materials differ in moisture content, shape and number of defects.

When determining the dimensions, the parameters must be considered for both layers with half a wane on each side: for example, there are unedged boards 25x6m, 50x6m.

Methods for installing a plank roof

There are several ways to construct a roof from edged boards.

- Cross laying. The boards are assembled across the roof slope. First of all, install the bottom board. Next, the next roofing element is overlapped by 50 millimeters. This is how the entire roof covering is erected up to the ridge.

- Longitudinal laying.

- The board is installed in one layer. In this case, the roofing material should be installed close to each other. The joints located on top are closed using flashings, which are wooden strips 20x50 millimeters;

- The roof covering made of plank is installed in two layers. In the first option, the layer located below is laid end to end. And the top row of boards is mounted so that their middle covers the joining gap of the bottom row and thus protects the roof from leaks. In the second option, the bottom row of boards is laid at a distance of 50 millimeters from each other, and the top row of roofing material covers these gaps. This option is used to facilitate the design, as well as to save building materials.

Green area on a flat roof

Green area on a flat roof

You can use a simple method in the arrangement: place pots with plants on the roof. But modern technologies make it possible to use a more interesting option. Green pets are planted directly on the roof. Geotextiles are an important participant in soil preparation. The fibrous synthetic material does not allow the soil to wash out and ensures the preservation of the structure.

A separating material is placed between the thermal insulation and the soil layer. Then follow:

- technoelast EPP;

- technoelast Green;

- geotextiles;

- fertile soil.

Green roof scheme