How and with what to tie the reinforcement? At first glance, it seems that the answer to this question is simple. We take a soft annealed knitting wire, a hook and get to work. But the experience of users of our portal suggests that even in such a simple matter there are a lot of nuances, starting from the choice of wire diameter and ending with the method of binding. However, these “little things” directly affect the speed of work and final costs. So, from this article you will learn:

- Is it profitable to tie a reinforcement cage with a battery-powered knitting gun?

- How to make a homemade hook for tying reinforcement.

- How to learn to crochet reinforcement.

Types of tools for knitting reinforcement

The knitting method involves using steel wire to manually fix rods perpendicular to each other in places where they intersect crosswise.

A crochet hook is a simple and safe tool that allows you to tie reinforcement bars quickly, securely and evenly.

Today, there are three types of ready-made hooks for knitting reinforcement bars, which can be purchased in the store. In addition, you can make a hook for the reinforcement yourself.

Manual

Photo of a purchased hook. The handle rotates freely.

A simple hook is a rod attached to a handle with bends that grip the wire. The hook for tying the reinforcement is rotated manually. The advantage of hand tools is their availability, durability and ease of use.

A hand crochet hook is an excellent option for novice builders, which will allow you to understand the knitting algorithm and feel the optimal degree of wire tension to obtain high-quality knots.

Screw

The knitting wire is selected with a diameter from 0.8 to 2 mm.

A semi-automatic hook is a reversible tool that operates by forward movements of the handle. The device has a rod with a hook in the form of a drill, which fits into the funnel of the handle along the thread, tightening the wire.

The cost of such a tool is higher than a manual one. But the screw tool makes it possible to cope with a wide range of work in a short time - in order to completely tighten the knot, it is enough to make only a couple of movements.

Mechanical

Builders who value every second choose an automatic hook (gun) for tying reinforcement. The operating principle of the gun is based on fully automatic rotation of the hook. This device is the most modern and advanced, allowing you to achieve maximum results and speed without large labor costs on the part of the builder.

Operating principle.

Buying such a hook for household purposes will not be justified: working with a gun requires a fairly large consumption of wire, and the cost of the device is high. But on large projects or when performing work that needs to be completed in an extremely short time, this option is ideal!

Homemade

Photo: hook made of wire with a diameter of 3-4 mm.

Purchased hooks are not always able to fully satisfy construction needs. Often, the shape of their rod has incorrect bends, and the length of the tools is made too short, which significantly affects the quality of work. So how then to make a hook for tying reinforcement correctly?

To make a device for tying reinforcement with your own hands, we will need a welding electrode or steel wire with a diameter of 4 mm.

In order to make a hook, you need:

- Make a handle for the device from a piece of thin hose to the size of a rod or trowel without a spatula.

- Insert the electrode into the hose or insert trowels into the funnel and secure (for example, using epoxy resin).

- Bend the rod at an angle of ninety degrees at a distance of about 5 cm from the handle (the bent rod should resemble a rocker in appearance).

- Bend the end of the rod in an arc.

- Before work, sharpen the sharp edge of the electrode using a file or sharpener.

A hook can be made from an unnecessary screwdriver or a handle from a construction roller, bending the sharp end at the required angle and sharpening it slightly. An automatic mechanism can be made by inserting an electrode rounded at the end into a screwdriver.

A homemade tool is perfect for household purposes, will save money and allow you to quickly knit even and reliable knots.

Popular manufacturers and prices for hooks in the store

Ready-made hooks for tying reinforcement cages can be purchased at any hardware store. We list the most popular manufacturers of manual and semi-automatic hooks, and prices for finished products:

- a manual hook for tying reinforcement from the Chinese manufacturer Remocolors Tools Limited can be purchased for 100 rubles. A semi-automatic hook from this manufacturer will cost 600-800 rubles;

- the semi-automatic Sparta tool from Germany costs 780 rubles. The RG 400T model, by adjusting the speed and tension, allows you to obtain strong connections with minimal wire consumption;

- hand hook from a domestic manufacturer Zubr, sold in a retail store for 250 rubles;

- a steel hook from China STAYER MASTER with a plastic handle costs 140-150 rubles.

Methods of knitting reinforcement

Let's consider all the existing ways to connect reinforcement. Each of the options is good in some way, and is used by builders, depending on the type of building and design requirements. There are 3 ways to connect rods; with their help, a strong and reliable metal frame is created:

- Wire knitting.

- Welding.

- Plastic clamps.

These methods of tying reinforcement have their own characteristics. Each of them is correct and is applied depending on the requirements and the material used. When reinforcing a strip foundation for a private house, the reinforcement is often connected by welding rather than tied with wire. But which option is the best?

Advantages and disadvantages of welding connections

Despite the fact that these are different technologies, the right choice can save money and time on construction, without sacrificing structural strength. The method of connecting elements by welding was previously considered one of the most reliable and effective. However, such technology is not always appropriate. Usually it was used when installing bulky frames that strengthen the foundation for multi-story buildings and large cottages.

This method has some disadvantages:

- You need to have skills in working with a welding machine, otherwise you need to spend money on the services of a professional welder. In this case, the cost increases.

- Welding points are the weak point of the structure. There the strength of the frame becomes lower.

- The method is not suitable if you use fiberglass reinforcement. In addition, the A-400 (A-3) fittings, which are the most popular, cannot be connected by welding. Only rods with the index “C” are suitable for work, for example: A500C reinforcement.

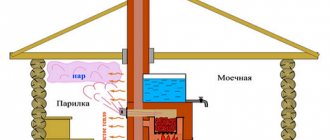

Therefore, in modern monolithic construction, welding has been replaced by viscous welding. For private and residential houses, construction of a bathhouse, garage or other buildings, this is the best option for connecting reinforcement.

Pros and cons of joining using the knitting method

Why is this method so good? It has the following positive aspects:

- Speed of work completion. Knitting with wire takes little time, it is simple and does not require skills. However, if you do it manually, the process slows down. Next we will look at how to quickly knit reinforcement.

- Ease of troubleshooting. When working with welding, it will be more difficult to eliminate errors; you will have to take a grinder and cut the welding seam. The wire can be simply bitten off with wire cutters or unwound with a crochet hook.

- You don't need to be a professional to knit reinforcement.

- The reinforcement process can be performed in formwork.

- The cost of work is much lower.

An example of knitting a mesh of reinforcement with wire.

If we talk about shortcomings, we note the precariousness of the finished frame. True, this is not a big problem. The structure will be strong, the only problem is that when the frame is moved into the formwork it begins to loosen, in this case it is possible to tack the reinforcement in several places by welding. To solve this problem with fiberglass reinforcement, you need to attach several braces to make the structure more rigid and stable. By bending, the tension in the knitting areas changes, the frame moves. Therefore, you need to be careful when installing it in the formwork. It is better to knit the reinforcement in the formwork or above it if the strip foundation is being reinforced.

Features of connecting reinforcement with plastic clamps

The main advantages of this method are that it does not require special skills, it has a high speed of work, and reliable fixation of the reinforcement. The disadvantages of this method are the following:

- Price. For large volumes, the wire will be more economical.

- Speed of work (when compared with other methods of knitting).

- Correction. You made a mistake somewhere, you will have to bite off the clamp, it becomes unusable, but the wire can be tied up.

- Reliability. It is not advisable to move around a structure connected with plastic clamps.

- Temperature. They burst at subzero temperatures.

Based on these data, we can say that this method is more suitable for private construction, with small volumes, and it is also suitable for people who want to do the reinforcement themselves with their own hands.

Eggplant diseases due to malnutrition

By following the rules for growing eggplants, you can significantly reduce the risk of diseases dangerous to the crop. And yet, even with proper watering and fertilizing, planting plants cannot achieve the proper yield.

In the southern regions of the country, gardeners may encounter a viral mosaic, manifested in changes in the color and shape of foliage. As the disease develops, alternating dark and light green areas appear on the leaf blades, more noticeable on the apical parts of the shoots. As a result, eggplant plants turn yellow, leaves are noticeably deformed, flowering and the number of ovaries decrease.

With viral internal necrosis, which also develops at high humidity, areas of dead brown tissue appear on eggplant fruits, which sharply reduces yield. The following techniques are used as preventive measures and to prevent the development of eggplant diseases:

- collecting seeds only from healthy ripened fruits;

- disinfection and selection of seed material;

- disinfection of soil at the site of planting and soil in seed containers;

- compliance with crop rotation;

- selection of healthy seedlings;

- destruction of plant residues in beds;

- compliance with agricultural technology standards.

To treat affected plants, taking precautions, use chemical and biological control drugs, carry out foliar feeding that increases the resistance of eggplants, and also be sure to disinfect the equipment used. Why do eggplants turn yellow, refuse to bear fruit, and die, seemingly for no apparent reason? Sometimes plants seriously suffer from an imbalance in the mineral composition of the soil, an excess or deficiency of essential nutrients.

Why do eggplants turn yellow, refuse to bear fruit, and die, seemingly for no apparent reason? Sometimes plants seriously suffer from an imbalance in the mineral composition of the soil, an excess or deficiency of essential nutrients.

Nitrogen has a direct effect on the growth of the bush, and the lack of this element negatively affects the size and appearance of leaves and shoots. They become small and pale. The fruits become deformed, do not develop properly and fall off. Excessive amounts of nitrogen provoke active growth of green mass and inhibition of fruit formation; moreover, the element can accumulate in the form of nitrates that are dangerous to humans.

Falling leaves and turning a purple hue is possible when there is a lack of phosphorus in the soil, one of the three main nutrients. But eggplants react especially acutely to potassium deficiency during the period of active fruiting. This is expressed in the fact that the eggplants turn yellow, the edges of the leaves dry out, and the fruits become covered with spots. Plants grown on acidic soils after liming, as well as during dry periods, have a special need for the element.

The development of plants is negatively affected by a lack of calcium and boron in the soil. And in such cases, eggplants look depressed and require urgent measures in the form of soil or foliar feeding.

https://youtube.com/watch?v=0XFFBAtoX0c

Source

Professional hook for fittings - use a gun

The knitting gun is a professional tool

Advantages of a professional device:

- there is no need to pre-cut the wire into blanks;

- wire is automatically fed from the working drum;

- material savings are achieved due to the absence of wire waste;

- increased pistol performance;

- increased loop tightening force;

- possibility of adjusting the twisting force and wire length.

Among the main advantages, it is necessary to note the possibility of autonomous operation from a battery, as well as the use of a special extension cord, which allows you to perform work while standing, without bending your body. The design of the device allows you to hold it in one hand, while the other hand supports the steel rods without the help of assistants. The duration of tightening the joint does not exceed one second. This is very convenient when performing work on an industrial scale.

Along with the advantages, there are also weaknesses:

- quite high price of a professional pistol;

- increased costs for purchasing special wire;

- inconvenience of use in confined spaces;

- the need to train knitters in how to work with the tool.

It is important to purchase consumables that correspond in cross-sectional size and rigidity to the characteristics of the gun. Otherwise, equipment damage may occur.

The gun is used by professionals when assembling the frames of large foundations. And at the same time, in certain places of the grille, fastening can only be done using hand tools.

Knitting gun BM-400

DIY wire jewelry. Copper wire pendant. Master Class.

For the pendant I took a 10 mm natural stone bead

You can take more or less - it doesn't matter that much. All pieces of copper wire 1 mm thick approximately 50 - 60 cm

I usually take long pieces of wire for work. You can always bite off the excess. What if at the end of the work there is not enough wire...? We insert one of the segments into the spiral and try it on around the bead.

We insert another 1 mm piece of wire into the hole of the bead and bend it as shown in the photo.

We begin to weave the wire with the bead using any method.

We weave together with the wire in a spiral.

Next, do as shown in the photographs. Various braiding methods can be found and watched on my YouTube channel. There’s even a separate playlist – Types of braids for wire jewelry

We cut off the excess ends of the wire, hide them behind the braids on the pendant, or make cute curls. We inspect the finished product and correct any flaws.

How to knit the frame?

When reinforcing a small volume of concrete, builders simply place the reinforcement in the formwork and then fill it with mortar. However, if large concrete products are to be reinforced, for example, a monolithic (slab) or massive strip foundation, then a frame is required. The reinforcement must be distributed evenly throughout the entire volume of concrete in order to reliably perform its function of increasing the strength of the structure. In these cases, a complex frame is made from metal rods.

crochet hook

The first option is the simplest and most accessible. If necessary, you can buy it in a specialized store for a hundred rubles or even cheaper. Moreover, it can be made by hand if the suitable material is available - we will return to this later. The downside is low performance. A novice knitter, with a sufficient supply of wire, will be able to produce 6-10 knitting per minute.

Screw hook

The screw hook is the next step in the development of the tool for knitting reinforcement. Outwardly, it looks a little like a regular one, but thanks to it, the knitting speed will increase, and the worker will get tired much less. If, when working with a regular hook, a specialist must twist the ends of the wire and manually twist them, then a screw hook is much more convenient.

Loop the loop and ends, then gently but firmly pull towards you. The plastic handle will be fixed in the hand, and the hook itself will begin to spin quickly, securely tightening the loop. Such a tool costs from 600 to 1000 rubles, depending on the manufacturer and store. It will be an excellent choice if you need to perform work once on a relatively large object. The knitting speed will increase, however, the wire will still have to be cut and bent by hand.

What to do and is it possible to eat such eggplants?

You cannot eat green, overgrown fruits unless you first remove the harmful alkaloid, but it is quite possible to remove it.

In case of solanine poisoning, nausea, vomiting, stomach pain, migraine, fever, diarrhea, and disorientation are observed. Then it is necessary to rinse the stomach and take sorbents (white coal, Enterasgel).

Important! The skin of green fruits must be cut off. The following manipulations significantly reduce the concentration of solanine:

The following manipulations significantly reduce the concentration of solanine:

- Eggplants are cut (in cubes, circles, bars) and sprinkled with salt. Leave for 30–60 minutes so that they release the juice. Then drain the juice, rinse the pieces well with water several times, washing out large seeds, place in a colander and squeeze.

- The pieces are soaked in salted water (1 tablespoon of salt per 1 liter of water) for 30 minutes and then squeezed out.

- The fruits are blanched for 5 minutes. at a gentle boil. After this, not only does the bitterness go away, but the skin also comes off easily.

- If the seeds are small and the eggplants are bitter, then just sprinkle them with salt for 30 minutes and then squeeze them out.

Instructions for crocheting reinforcement

It is useless to knit the reinforcement with your bare hands - you can achieve the required force to tighten the wire only with the help of additional tools. Let's take a step-by-step look at the basic techniques for crocheting reinforcement.

Manual

To knit wire by hand you will need a hook. The wire is folded in half and hooked under the fixation point. The free end is threaded into a loop and crocheted until the wire is tightly tensioned.

Simple knot

To tie a wire with a simple knot, you will need to do the following:

- A wire 200 mm long is cut and bent in half.

- The bent section is pushed under the point where the two rods meet.

- The hook is inserted into the loop and catches the free end.

- A full revolution is performed around its axis. The free end must be held.

- Next, while tensioning the wire, the hook is turned several more times until a reliable connection is obtained.

You don't have to buy a hook at the store. You can easily make a convenient tool yourself by giving the required shape to a steel rod and putting a handle on the end.

Dead node

Before crocheting foundation reinforcement, you need to learn how to form a dead knot. This method is especially good for tying vertical rods for columns and beams.

- A piece up to 400 mm long is cut and bent in half.

- The segment is pushed forward by a loop from below the knot being fastened.

- The free end is passed through the top and again bent under the rods.

- The loop and the free end are aligned and then hooked with the hook tip.

- The hook is rotated with tension until the loop comes off.

To obtain a high-quality connection, you need to ensure that the wire is tightly laid on the surface of the reinforcement. The knitting process continues in a checkerboard pattern.

Screwdriver

The scheme of working with a screwdriver is reminiscent of the crocheting process, but instead of manual force, automation is used. Instead of a regular tip, a homemade hook is inserted into the screwdriver; usually a roofing nail is used for this purpose.

It is important to ensure that the speed of the screwdriver corresponds to the required force for tightening the wire. If you apply too much force, the wire will break, and at low speed you may end up with a weak knot.

Popular manufacturers and prices for hooks in the store

Ready-made hooks for tying reinforcement cages can be purchased at any hardware store. We list the most popular manufacturers of manual and semi-automatic hooks, and prices for finished products:

- a manual hook for tying reinforcement from the Chinese manufacturer Remocolors Tools Limited can be purchased for 100 rubles. A semi-automatic hook from this manufacturer will cost 600-800 rubles;

- the semi-automatic Sparta tool from Germany costs 780 rubles. The RG 400T model, by adjusting the speed and tension, allows you to obtain strong connections with minimal wire consumption;

- hand hook from a domestic manufacturer Zubr, sold in a retail store for 250 rubles;

- a steel hook from China STAYER MASTER with a plastic handle costs 140-150 rubles.

Automatic hook for tying reinforcement

A special device with a reverse operating principle allows you to speed up and automate the twisting process. At first glance, it looks like a standard manual device, but differs in the presence of a screw mechanism consisting of the following parts:

- plastic handle with internal screw thread;

- working body with a screw thread on the rod.

When assembled, these elements form a mechanism with a reciprocating principle of operation. The reversible device works quite simply - moving the handle causes rotation of the working element on which the wire loop is put.

Advantages of the reversible device:

- increased wire binding performance;

- Possibility of use in areas with limited access;

Automatic hook for tying reinforcement

- ease of knitting operations;

- durability of the device with regular lubrication.

The device has the only drawback - its increased price when compared with the cost of a conventional hand tool.

Using a reversible tool, the knitter can perform an increased amount of work without getting tired. The screw device is superior in efficiency to the manual device when it is necessary to manually pull and twist the wire ends. Without reinstalling the working hook, by cyclically moving the handle you can achieve reliable fastening.

Procedure for using the device:

- Insert the hook of the tool into the twisted loop.

- Pull the handle towards you along the working axis.

- Return the handle to the starting position.

- Perform the next movement cycle.

You can also make your own semi-automatic tightening device using a regular screwdriver. You will need a bent nail without a head or an L-shaped rod, the end of which must be inserted into the tool chuck. With a little practice, it is not difficult to master the principles of operation using this device.

Why do ripe eggplants turn green?

Eggplants, like all nightshade crops, are capable of accumulating the toxic alkaloid solanine. It is this alkaloid that gives them a bitter taste. In young fruits its content is tolerable and quite acceptable, but when overripe they begin to become very bitter and change color to green, yellow or brown. The pulp inside quickly turns brown, and the seeds become ripe and also darken.

It should be taken into account that there are varieties of eggplants that have greenish tones in the skin when ripe.

They are popular in Asia, but we also have, for example, the Emerald variety, which has a green or whitish skin and creamy white flesh that is not bitter and has a mushroom flavor. And sometimes eggplants do not turn blue due to the fact that their development is inhibited by an excess of nitrogen or the fruits become lightened and do not turn blue due to a lack of light.

Did you know? Increased doses of solanine may be found in potatoes that have sprouted or turned green in the sun. It is most concentrated in the sprouts and skin. The harmful alkaloid is also present in unripe tomatoes, but when they grow and begin to change color, they can be used for preparations.

Related Posts via Categories

- How to calculate the cross-sectional area of reinforcement of all types?

- How much does 1 meter of construction rod reinforcement of various types weigh?

- Length of rod reinforcement - all possible options regulated by GOSTs

- Linear fittings – high-quality installation of power lines is guaranteed!

- Unmeasured reinforcement is the best option for low-rise construction!

- Brands and classes of construction rod reinforcement and wire for reinforcement

- Coupling fittings, what they are and what they are used for

- Anchoring reinforcement in concrete is a complex but important operation

- Hot-rolled reinforcement - GOST and the entire life cycle of the product

- Weight and features of steel corrugated reinforcement A3 and other classes

Making your own hook

Despite the low cost of a crochet hook for reinforcement, some experienced craftsmen who have worked with reinforcement for many years prefer to use homemade ones rather than purchased ones. This has its advantages.

- When making it yourself, you can give the handle the optimal shape so that it fits comfortably in your hand. Your hand will get less tired and your productivity will increase.

- The choice of steel for production; you often come across factory hooks made of soft metal. As a result, it cannot withstand the load and bends.

- Make a hook for crocheting reinforcement of the required size. There are times when it is impossible to get to the place of tying with a factory hook because of its length.

- Small, but still savings (if materials and tools are available).

Electrode hook

An electrode hook is suitable for small amounts of work. When it is necessary to tie a small frame from reinforcement.

Making a hook with your own hands takes only 5 minutes. You will need: electrode 4, pliers and a grinder (if not, you can do without it).

Let's look at how to do it step by step:

- We beat the electrode off the protective coating.

- We retreat 1-2 centimeters from the edge and bend it at 80-90 degrees.

- We retreat 3-4 centimeters from the other edge, make the first bend at 90 degrees. We retreat another 10-12 centimeters, and make a second bend at 90 degrees. We retreat another 4-5 centimeters and make a third bend.

- Let's sharpen the tip of the hook a little so that the wire can peel off better.

The hook is ready, it should have the same shape as in the drawing below.

Homemade hook made from rebar with a wooden handle

A homemade hook is most often used by professional reinforcers, thanks to the advantages described above. Its production will take about 2 hours, and the result will be a hook that is in no way inferior to the factory one.

To make a hook you will need the following materials and tools:

- Corrugated fittings 8-10 in diameter, 35-50 centimeters long;

- wooden blank for handle;

- 2 washers - the diameter is equal to the hook handle;

- 2 nuts;

- pliers, knife or hatchet;

- grinders and welding;

- drill with drill 8-10 diameter;

- sandpaper.

Manufacturing procedure:

We grind the ribs of the reinforcement on a grinder so that it becomes smooth. We take a corrugated one, not a smooth one, since a higher grade of steel is used for its production, the hook will be stronger. Let's prepare the pen. Using a drill, a drill of a suitable diameter, drill a hole in the center of the workpiece. Afterwards, if necessary, we adjust it to the required size using a knife or hatchet. At the same time, make sure that the hole is in the center of the handle. Next, sand the handle until smooth with sandpaper. We put a nut on the edge of the reinforcement and weld it by welding. Put a washer on top of the nut, then put on the handle, then the washer and nut again

It is important that there is a small gap between the washers and the handle so that the hook handle can rotate well. To do this, place a piece of paper folded a couple of times between them.

Then weld the second nut. Be sure to place water near you so that if the pen catches fire, you can immediately extinguish it. Now we will sharpen the edge of the reinforcement with a grinder, do not overdo it so that it does not turn out too thin, otherwise the crochet hook will bend. We retreat 1-2 cm from the edge of the handle and make a bend at 90-140 degrees (it all depends on the chosen type of hook, see examples of bends in the picture below). We retreat 1-2 centimeters from the edge of the reinforcement and bend the tip of the hook with pliers at 80-100 degrees. Make sure that the bends are in the same plane. To increase the service life of the handle, we cover it with impregnation for wood against rotting and moisture in 2 layers. After drying, coat it with wood varnish. The hook is ready, all that remains is to make a couple of ties for testing; if it fits well, then you don’t need to bend anything, otherwise you can bend it a little to fit your hand.

Photos of handmade hooks for tying reinforcement

We recommend watching the video instructions for one of the options for making a crochet hook with your own hands.

That's all. Now you have not only learned about knitting devices, but also learned how to make a hook for tying reinforcement with your own hands and can easily cope with this task.

Planting and care

Seeds are planted using the seedling method. To do this, the seeds are treated with a solution of potassium permanganate to prevent diseases and dried. Take a container and fill it with soil with humus or peat, watering it with water. Seeds are sown in the resulting soil at a distance of 2 cm from each other to a depth of 1 cm.

It is necessary to cover the seedlings with plastic wrap and ensure that the room temperature does not fall below 20 degrees.

At the stage of 2 true leaves, the seedlings are planted in separate containers made of peat or plastic. On days 55-65, the seedlings are transplanted into the ground. You should plant 6-7 tomatoes per square meter for good nutrition and high yield.

Tomatoes are regularly watered with warm, settled water when the soil dries out. Between waterings, the soil is loosened and weeded, which protects the plant from fungal diseases and gives it additional nutrition.

Once every 12 days, mineral fertilizers are applied until the fruits begin to ripen. Organic fertilizers are diluted in water for irrigation so as not to burn the roots.

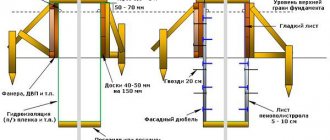

Important recommendations for choosing reinforcement for the foundation

Diameter

When choosing reinforcement for the foundation, first of all, pay attention to the diameter of the rods. The relationship is simple: the thicker the reinforcement, the more severe loads it can withstand

When determining the optimal diameter, first of all, the characteristics of the soil are taken into account (the main point is heaving) and the expected weight of the finished building, taking into account the weight of its internal arrangement and residents/visitors.

This is how it should be ideally and according to the rules. Along with this, many private developers refuse to draw up design documentation and perform related extensive calculations, adhering to average and generally accepted values. In the case of the construction of relatively small buildings, for example, such as a bathhouse, such an approach is acceptable.

The recommendations are as follows:

- if the structure is erected from relatively light materials (timber, gas blocks and other lightweight building elements from this series), reinforcement with a diameter of 1.2 cm is used. It is impossible to use rods with a diameter of less than 12 mm for arranging the foundation - reinforcement so modest in its overall characteristics is only suitable for use in the construction of supports for fences, gates and other light utility structures;

- if construction is carried out using heavier materials, the recommended diameter of the reinforcement changes accordingly. In most cases, rods with a diameter of 1.4-1.6 mm are used.

Assortment of fittings

Class

The second important indicator is the class of the reinforcement. For a private foundation, class A-3 material is suitable.

Corrugated fittings A3, steel grade A500S, GOST 5781-82

The fittings of this group are very easy to use (easily bends without the use of special tools), durable and reliable. Less commonly used are rods of class A-2 (they can be bent 180 degrees, A-3 – 90 degrees).

Table of reinforcement classes and steel grades

The nuances of working with the foundation reinforcing belt

A strip foundation for a residential or public building inevitably has corners. It is unacceptable to arrange reinforcement in them using the method of sequential connection of frame rods. A larger overlap of reinforcement during tying and special reinforcement schemes are used.

When figuring out how to knit reinforcement at the corners, the designer of the reinforcement scheme gives preference to L-shaped or T-shaped reinforcement, depending on the responsibility of the structure and the possibilities of using one or another form.

When lengthening the rods, an overlap of 20 or more rod diameters is used, and such joints should be spaced so that in one section there is no more than half of the horizontal spliced rods.

Important: in order not to impair the performance properties of the reinforcement, rods can only be bent in a special mill or holder. It is highly undesirable to use gas welding! Related to the danger of corrosion at the welding site is the question of why reinforcement is knitted and not welded.

Welding (arc, not spot) is permissible for rod diameters greater than 25 mm.