Sleeves for pipeline passage: structure, types, equipment

If you have a private house or cottage, then this issue will become one of the decisive ones, because any building needs a water supply system, a gas pipeline and a sewerage system. In the twenty-first century, there are a huge number of opportunities to protect housing from environmental and atmospheric influences. The safest and lowest-cost method is to install sleeves.

In most cases, pipeline sleeves must be used

Several theses follow from this.

- Do I need to use sleeves or other materials to pass pipes through walls?

- Which cases are better?

- Which material is the most resistant?

- What is the internal volume of penetration in the floors?

- How to seal?

- At what distance from the partitions should it be located?

- What installation difficulties can you encounter?

- Is it possible to lay heating through walls using a sleeve?

Read the article and you will find the answers you are interested in.

Installing sleeves is the most cost-effective and safest way

Structure of sleeves in walls and ceilings

The first requirement when integrating pipelines, gas pipelines and sewerage into building structures is the continuity of the insulating layer. This requirement is due to the fact that in the presence of cracks, holes and other defects, air and dust begin to enter the pipes, as a result of which they are deformed and destroyed.

Naturally, after building a residential building, you do not want to encounter a similar problem, the solution of which will not only take a huge amount of time, but also waste of materials, up to partial or complete re-filling of the foundation (floors).

To prevent such moments, there are sleeves for pipelines, sewers, and cables.

The issue with sleeves needs to be resolved during construction, then it will be problematic

Types of pipeline sleeves (material)

- Metal sleeve

- Fireproof (clay, ceramic) sleeve

- Polymer sleeve

Steel sleeve is the most reliable option

- Steel is the most durable and expensive material that is suitable for almost any floor.

They are used on large-scale construction sites, as they can withstand pressures of up to 120 tons per 1 square meter. They are also very popular in the construction of reinforced concrete structures - they can be concreted not only at the construction site, but also in the production workshop. The edges of such a part must be sanded so as not to damage the polypropylene pipes inside. - Fireproof - distinguish between clay and ceramic. Used as an insulating material for chimneys. The main disadvantage is fragility, which means be careful when installing (you can not only break your purchase, but also get a cut injury).

- Polymer - used in interior floors for pipelines and cables. The main distinguishing feature of the material remains wear resistance and cold resistance.

Each material has its own characteristics and disadvantages

Equipment

Before choosing a material for construction, carefully check the pros and cons, taking into account the surface surrounding the sleeve, the size of the pipe itself, safety and previously integrated systems. The most important advantage is the acceleration of repair work. In addition, thanks to the arrangement of protection, you increase the wear resistance of the line and simplify their possible future replacement.

Pipeline diagram with sleeve

The most vulnerable parts are their gaps. When assembling, it is recommended to place the joints so that they do not lie in the same plane, and the longitudinal seams are shifted relative to each other by 1-1.5 centimeters.

Where pipes pass through building structures, it is necessary to insert sleeves from pipes of larger diameter with a soft gasket. The cartridges are inserted before placing the material and covered with concrete mortar. In addition, the specifics of the passage of pipes through the wall are directly related to the type of communications being laid.

Each method is determined by individual nuances, therefore, in order to provide individual protection to the internal life, we will consider the designs “in cross-section”.

When installing sleeves, many nuances are taken into account

- Plumbing In the case where the installation is made of steel parts, a protective coating is applied to them at the junctions with building elements to prevent the ingress of debris. If the pipeline is intended for cold water supply, a cover will be required.

It will help avoid moisture condensation on the surface, thereby making the channel last decades longer. If plastic profiles are used for laying, then you should first look at the instructions for it.If there are seals in the parts of the pipeline entrance to the room with the possibility of groundwater runoff, then waterproofing couplings are used in them and covered with concrete mortar so that liquid does not leak into the lower tiers of the building.

If steel parts are installed, they are treated with a protective layer at the end

- Drain pipes The specific design of cast iron caps lies in their difference from other materials that require reinforcement and sound insulation when crossing pipelines.

To do this, you need a steel cartridge with a gap of 20-25mm. must exceed the pipe. The specificity of the design of cast iron caps lies in their difference from other materials - Steam heating In a steam heating system for internal rooms, sleeves play a primary role.

If they are not installed, temperature changes will lead to deformation of the main line and the formation of cracks in the ceilings. Just like for installing hot water plumbing, you should rely on polypropylene caps. The fastening mechanism is distinctive; during production it is characterized by high heat resistance and maintains a high and constant temperature from the inside. Based on this, do not rush into purchasing, but properly study the offers of manufacturers who not only meet your criteria, but also meet the criteria of SNiP. This will save your strength and resources. Installation of sleeves for steam heating is a mandatory procedure - Size of the inner diameter of the sleeve This point becomes decisive when installing equipment in partitions, therefore it must be approached with the utmost care and pickiness.

If the outer and inner diameters of the sleeve for the hot heating pipeline do not match, the most unexpected surprises may appear. The structure must be chosen so that passage through the floors is free. The parts have similar technical gasket features, but at the same time have different endurance. When the pipe is laid through the ceilings, it is necessary to connect the sleeves, the outer diameter of which should be 10-15 mm wider than the pipe, with a gap of 2-3 cm. In this case, the case itself must be tightly secured in the passage hole. The gaps between them are sealed with glass wool. For metal-plastic pipes, when passing through building structures, try to install fasteners made of plastic pipes with a slightly larger outer diameter. As a result, in order not to make a mistake with the cost and reliability of the work done, we recommend that you turn to professionals - they will save both nerves and time. The issue of sleeve size must be approached with maximum care and pickiness. - Sealing

To protect the pump when crossing pipelines and partitions, it is recommended to seal them tightly so that even small gaps do not remain. The inner diameter of the sleeve should be 30mm wider than the thickness of the pipe. We insert washers with angular threads with a longitudinal section of 3-4 mm onto the connections.

Pipe sealing should be maximum

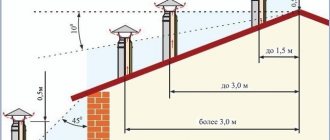

Passage of a flue through the wall of a building

The most successful way to exit the gas duct in the partition is from the pediment side. But if this cannot be done and the chimney comes out from the side of the slope, then we weld the stand and attach the structure to it with sliding fasteners. The result is an intelligent and long-lived system.

Diagram of the chimney exit through the wall and one of the implementation options

: Water pipe sleeve connection

Source: https://couo.ru/kvartira-i-zagorodnyj-dom/stroitelstvo-i-remont/vybiraem-gilzu-dlya-proxoda-truboprovoda-cherez-stenu.html

Making or buying?

You can find a large number of ready-made solutions on sale - from inexpensive stamped 20-ruble sleeves of small diameter to products made of thick-walled structural steel. Almost all cases are universal, that is, they are used for making penetrations for any communications, including gas ones.

To protect against exposure to a humid environment, manufacturers apply a zinc coating or paint to the metal. The products are suitable for installation in any type of wall and have fire safety certificates

But if you don’t want to use a purchased part, and you have a lot of material left over from building a house, then you can make a sleeve with your own hands. A large diameter pipe is suitable, according to the standards - exceeding the gas pipe by about 20 mm.

A fragment is cut from the pipe, equal in length to the width of the wall - its edges should not protrude beyond the surface. The ends are cleaned so that they do not have burrs or sharp edges. Then the workpiece is coated with protective paint for metal, preferably in 2 layers - the sleeve is ready.

Sleeve for passing pipes through the wall

- Articles

- Articles about Construction

- Sleeve for passing pipes through the wall

For internal walls and ceilings, a number of civil and industrial buildings, in most cases the following is necessary: • expansion couplings for passage through the wall - to level out the temperature expansion of the pipelines themselves; • fire protection couplings - to provide protection against flame penetration into adjacent rooms during a fire.

All these requirements are provided by the sleeve and couplings for the passage of pipes through the walls.

Features of the passage of pipelines through building structures

An incorrectly installed pipeline creates a potential danger of an emergency. Inside the building structure there are a large number of different utility networks. Communications of different materials and strength can pass through the same building elements. The technology for running a pipeline through building structures depends on their type and the material of its components. The latter can be made of copper, steel or various plastics.

How to ensure maximum service life of building structures and pipelines?

There are a number of recommendations: • According to SNiP standards, non-insulated units should not have direct contact with building structures; • Before the horizontal outlet, protection is provided with a cement layer of several centimeters; • Use sleeves (cases) in places where pipelines cross; • To increase sound insulation properties, an elastic material is used, which is placed in the gap between the outer diameter of the pipe and the inner diameter of the case; • Sleeve waterproofing can only be used for slabs; • During installation, uneven shrinkage of the foundation is taken into account: gaps are sealed with mastic or sealants. Moreover, the internal diameter of the case must exceed the diameter of the pipe by 2 cm; • Copper components are also placed in cases, and the border with the building structure is treated with cement, in wooden houses - with asbestos;

• Changes due to temperature changes are compensated by means of sliding supports, which must be taken into account during the creation of the project. At the exit, install a fitting (tee, elbow) to prevent it from being removed from the wall.

Laying pipes through ceilings

There are 2 main caveats: • When using flammable insulation, the space around the pipe must be treated with basalt fiber, which does not burn. • The minimum distance to wooden structures must be more than 13 cm. To create a unit, an opening is made in the ceiling, the lower part is strengthened and a pipe is passed through it. It is important that the joints of the components are not in the ceiling-passage assembly. A sleeve with a protrusion thickness is inserted (SNiP 2.04.01).

• Cement mortar is used to treat the area 10 cm above the ceiling, the layer should be a couple of centimeters 2-3 cm. • Pipes should be wrapped in waterproofing material, excluding gaps, and only then plastered. • Thermal elongation of pipes must be taken into account. • When the pipe passes through the ceilings, its free movement is ensured, i.e. install the sleeves. Moreover, their internal caliber should be 5-10 mm larger than the size of the pipe.

The space is sealed with soft material with non-flammable properties, which will allow the pipe to move freely. The protective case can be made of plastic or metal.

There are also additional requirements depending on the type of pipeline and purpose of the room, installation method.

Sleeves are used for the following reasons: • Straight sections of a polymer pipeline are susceptible to temperature changes, which requires free movement during thermal deformation. • For the possibility of dismantling if a section of the pipeline is damaged.

However, in some cases, the use of sleeves in building structures is not economically justified. In addition, sealing the space prevents the occurrence of unpleasant odors and insects. When using the sleeve in wet rooms, the seal must ensure tightness: water should not enter through the gap into the adjacent room.

Installation of sleeves in walls and ceilings for utility networks

The sleeve should protrude beyond the wall. However, some features should be taken into account: • The standard requirement is a 50 mm output, but this is not always justified. • In rooms where the possible water level is higher than the clean floor (bathtub), a hermetically sealed sleeve near the pipeline is required. • Sometimes the case can protrude only 5-7 mm, since it is not economically feasible to make it large.

• The sleeve should not be an obstacle to the finishing of the walls - protrude beyond the plaster or wallpaper. The size of the gap should ensure high-quality sealing with material. The inner diameter must allow free movement of the pipe. Practice has shown that sleeves are made from sections of polymer or metal pipes. In some cases, it is possible to use a rolled waterproofing material - roofing felt.

But it is worth remembering that they contain petroleum components. This is undesirable for wooden building structures. Non-metallic sleeves have an advantage. No burrs or sharp ends that often scratch polymer pipeline components. To solve the problem, the edges of the steel sleeves are processed and flared outward.

Plastic, in turn, does not have good adhesion to cement mortar.

The thickness of the walls is determined by the type and objectives of the structure.

Gas duct passage through a wall, passage unit

A sleeve is also used to lay the gas duct. It is made from pipe according to GOST 10704-91. In external walls, the protective casing must protrude 20-25 mm onto the street. Moreover, on this side, the gap between the pipe and the sleeve should be sealed with grade 4 bitumen. The remaining gap is sealed with tarred tow. The internal size of the case should be 20-30 cm smaller.

It must be sealed with cement mortar in the wall. Further installation is possible only after the sleeve has completely dried and secured. Considering the level of responsibility during the construction of gas mains, as well as the fact that all gas systems are subject to mandatory acceptance by service organizations, it is necessary to adhere to the requirements for the passage of gas mains through walls and ceilings with 100% accuracy.

When the pipe passes through the roof, a sleeve is also installed. It should protrude 30 cm above the outer surface of the roof, and 2 cm above the inner surface. The space between the pipe and the sleeve is also clogged with tarred tow; it is not necessary to use bitumen. The sleeve itself must be cemented only in the concrete part of the floor.

The outer part of the sleeve from the street and the outgoing gas pipeline are protected from moisture by metal linings. Any seal must provide for the possibility of replacing or additionally installing new components.

Additionally: you need to understand that sleeves for ventilation pipes differ from special roofing transitions used to remove the chimney.

The use of sleeves when installing pipelines through building elements is rational and justified. In most cases, this is a requirement of construction SNiPs. The sleeve will allow timely replacement of pipeline components, provide insulation from the wall surface and compensate for the thermal expansion of the material.

Checkout Categories

SIMILAR ARTICLES

Types of roofing materials for arranging the roof of a private house

With the development of private construction, the building materials market has expanded significantly, and a clear example is the modern range of roofing materials. Classic tiles and budget slate have been replaced by a wide variety of soft and hard, rolled and piece materials.

Source: https://www.promstok.com/articles/stroitelstvo/gilza-dlya-prokhoda-trub-cherez-stenu/

Features of introducing a gas pipeline into a house

The lining process itself is accessible to anyone who has held a hammer drill in their hand and participated in the construction of a house. But there are a number of nuances that are required for any work involving gas connections and gas equipment. This is due to both the protection of the pipeline and the safety of residents.

First, let's look at what a gas pipe case is and why it is needed, and then we'll take a closer look at the process of laying a gas pipeline through a wall.

At what stage is the case installed?

The gas system located from the point of insertion into the central gas distribution main to the equipment installed in the house is called an internal gas pipeline. Simply put, this is not only a wiring installed inside the house, but also a branch located in the yard - underground, above the ground and in an area near the wall of the building.

An underground gas pipeline, accordingly, is included in the project for connecting gas to the house. According to the standards, low pressure gas is supplied to residential buildings - this is important when choosing equipment.

The question arises: when and where is it better to install a casing for introducing the pipe into the house? Theoretically, this can be done immediately after the project is approved, when the exact locations of the installation of gas equipment and the exit of the pipeline from the ground are known.

Usually they strive to reduce the distance between these two points, that is, the gas main is brought out as close as possible to the boiler room of the house or other non-residential premises where gas units are planned to be installed or have already been installed - water heaters, boilers, stoves.

It is best to make a hole in the wall when the gas pipeline outlet from the ground to the outside is already equipped. If the main line is above ground, then after connecting it to the house, in order to more accurately determine the entry point. In other words, the most favorable moment for laying a gas pipeline in a case is the completion of internal and external work.

Why is lining necessary?

According to regulatory requirements, it is prohibited to conduct any communications - gas, water supply, heating, sewer pipes, chimneys and ventilation ducts - through walls without additional reinforcement.

The protective structure is a case or sleeve - a durable metal casing that protects the pipe from mechanical damage.

The main task of the casing on a steel internal gas pipeline is to take the stress of the wall and relieve the load from the pipeline. The use of cases is typical for work on the installation of gas mains.

For example, it is mandatory when laying gas pipes under automobile or railway tracks, as well as in soils that do not fully meet the installation conditions - heaving or flooded.

The wall mounting case is different from the special equipment placed when installing distribution lines, however, it must also be durable and wear-resistant.

Sleeves for passing pipes through walls SNIP - Club of Masters

> Walls >

02.11.2019

Installation of pipelines in capital structures requires a serious approach already at the network planning stage. It is equally important to take into account all the nuances of the operation of communications when replacing old highways. The points where pipes pass through walls, floors and foundations are concentrators of deformation stress.

In these areas, network elements are subject to mechanical and chemical influence, therefore, in accordance with building codes and regulations, they are supplied with additional structural elements - sleeves.

What are sleeves for passing pipes through walls, SNiP restrictions in this direction, the nuances of the device - you will now receive all this information in full in order to understand this topic.

Important little things

The pipeline sleeve is an important element. And this applies to communications of various buildings - residential, office or industrial. The part performs a number of functions: mechanical, protective, waterproofing, fire protection, sanitary, and also increases the service life of pipelines and facilitates their replacement. The design of sleeves for the pipeline depends on its type.

Common types of pipelines for capital structures are as follows:

- cold and hot water supply;

- drainage system (internal sewerage);

- steam heating heat pipeline;

- stove chimney.

Elements passing through the building structures can be metal (usually steel, less often copper), plastic (polyvinyl chloride or polypropylene), or a combination (plastic encased in an aluminum alloy). For the installation of sleeves, the material of the products passing through interior walls and interfloor ceilings, as well as the material of building structures, is important. Typically the pipeline is steel, the walls are brick, and the ceilings are reinforced concrete.

Product design

The pipeline can cross building structures in two planes. Interfloor ceilings are crossed by vertical pipelines (risers), walls - by horizontal ones (wiring). The figure shows an example of the installation of a product in walls (a) and ceilings (b).

Actually, the sleeve consists of a cover (1), for which a steel structure is most often used, packing (2), which can be a soft non-flammable material, but Portland cement is often used (which, according to experts, is undesirable). The cover is firmly fixed. The pipe (3) passes freely through the cover (the diameter of which should be 5-10 mm larger than the pipe) and is fixed in the wall (4) or ceiling (6).

Installation and caulking of pipeline sleeves in floors is carried out taking into account the height of the screed (5) or other floor covering, and the length of the product should be at least 10, or even 20 mm, greater than the thickness of the floor. This is important to prevent emergency water masses from penetrating to the lower floors.

This is important to know! The section of pipe where it passes through the wall should not have seams.

Types of pipelines

The order in which networks pass through walls or ceilings largely depends on what kind of communications are being laid. Let's figure it out.

Water pipes

If this network is installed using steel products, the general recommendations outlined above should be used. In this case, the surface of the pipe in the area where the wall or ceiling intersects must be protected with a moisture-resistant coating. For cold water supply, it is also necessary to provide a thermal cover, which will prevent the formation of condensation on the surface of the line and will extend the service life. When using a polymer or combined pipe, you must follow the manufacturer's recommendations set out in the product annotations.

If there is groundwater pressure at the entry point of the pipeline into the house, then special waterproofing sleeves can be used to prevent water masses from entering the internal (basement) rooms.

Sewerage

Cast iron products do not require sound insulation and reinforcement, and also do not require the mandatory arrangement of sleeves, which, however, can complicate the process of repair work. Plastic requires a steel pipe sleeve; for example, a larger cross-section product made from roofing steel can be used. The diameter of the part should be 15-20 mm greater than that of the pipe, and the length should be 20-30 mm greater than the width of the wall. The structure at the point of passage through the ceiling is wrapped with waterproofing material, and the passage section itself is sealed with cement mortar.

Worth paying attention! Do not use roofing felt or other organic materials that have an adverse effect on the plastic as wrapping material.

Heat pipe for steam heating

The mandatory use of sleeves for steam heating networks is due to thermal deformations of the metal and stress on straight sections of pipes during sudden temperature changes, which can cause the formation of cracks in building structures and failure of the heating system. In fact, the design and position of the sleeve for passing through ceilings is identical to that for hot water supply systems.

When passing through interior walls, not steel, but combined or plastic pipelines from various manufacturers can be used. Their specifications provide for individual fastening and connecting elements, including a sleeve for passing pipes through the wall.

Often these parts are high-tech and provide the required level of pipe sliding, which is due to different parameters of expansion and deformation of plastic from different manufacturers.

Chimney

If the chimney is made of steel elements, then when passing through the ceilings it is necessary to use a hollow galvanized iron sleeve, while the upper and lower surfaces are additionally insulated with a fireproof plate. If building structures are made of flammable materials (for example, wood), then the outside of the hollow sleeve is additionally insulated with non-flammable insulation, for example, basalt fiber or asbestos. From a fire safety point of view, the arrangement of the chimney passage in the roof requires special attention.

Do not forget to follow building codes and regulations, and you are already familiar with the main subtleties and nuances of installing liners.

Insulation of pipe entries: the most effective methods

The main task when laying a pipeline is to create a waterproofing barrier that will ensure dryness of the holes in the partitions and walls through which utility networks are installed. There are several most effective ways to isolate them using modern sealing adhesives and solutions:

- sealant + protective cuff (if the wall hole has uneven edges, it is additionally protected from the ingress of contaminants (earth, stones), for which a cuff is installed on the outside that can withstand hydrostatic pressure up to 5 bar, and on the inside it is sealed with epoxy sealing sealants) ;

- end seal + overlay flange (if the concrete wall or partition is covered with microcracks, a remote insulating element consisting of an overlay flange sleeve in which the end seal is placed will help prevent moisture from penetrating through them);

- embedded sleeve + sealant (the method is optimal when running a power cable through the wall, which is passed through a sleeve made of plastic or fiber cement, and the space between its walls and the electrical wire is filled with a sealing compound);

- adhesive sealant (the gap between the pipeline and the edges of the hole can be completely filled with a waterproofing solution without installing additional parts - this method is cheap and reliable, since synthetic elastomers will penetrate into all irregularities and voids, harden in them and provide 100% waterproofing of communication inputs).

Not a single method of establishing communications is complete without the use of special insulating compounds. But how to choose a material and what characteristics to pay attention to?

The wisdom of installing liners for pipelines

Installation of pipelines in capital structures requires a serious approach already at the network planning stage. It is equally important to take into account all the nuances of the operation of communications when replacing old highways. The points where pipes pass through walls, floors and foundations are concentrators of deformation stress.

In these areas, network elements are subject to mechanical and chemical influence, therefore, in accordance with building codes and regulations, they are supplied with additional structural elements - sleeves.

What are sleeves for passing pipes through walls, SNiP restrictions in this direction, the nuances of the device - you will now receive all this information in full in order to understand this topic.

Meet the main character of the article

Material

To make a sleeve for sewer pipes, a passage through the ceiling can be used:

- Metal. Steel products are characterized by strength, reliability and durability. They can be installed in any ceiling. Steel products can withstand loads of more than 100 kg per 1 m 2 . Pipeline protection can be installed directly at the construction site and at one of the stages of manufacturing a reinforced concrete structure. Before concreting, the edges are sanded to prevent damage to the polypropylene pipeline.

- Polymer materials. A polymer sleeve is used to arrange the sewerage passage through the ceiling between floors. The material is resistant to wear and low temperatures.

Nuances of heating systems

When installing heating systems in houses, some of the pipes end up in the thickness of foundations, ceilings, walls, etc. Technical standards provide certain recommendations for organizing the combination of pipelines with building structures.

For example, the places where the risers pass through the ceilings must be sealed with cement to the full thickness of the ceiling being organized, and the perimeter 80-100 mm above the ceiling must be protected with a cement layer of 20-30 mm. Before sealing the riser with pipe mortar, you should wrap it with rolled construction waterproofing without a gap.

Another important point: when a polypropylene heating pipe passes through building structures, a specially designed pipe sleeve must be provided.

Diagram of a pipe in a sleeve.

The interpipe space is sealed with soft, non-flammable material so as not to interfere with changes in the physical parameters of the pipeline during its linear temperature deformations.

Equipping pipelines with sleeves: necessity or desire

The use of specially designed sleeves when crossing heating pipes of walls and ceilings of buildings is justified for a number of reasons:

Scheme of installing a pipe into a sleeve.

- Sections of polymer risers are extremely sensitive to temperature changes, which, accordingly, affects their ability to significantly move. Installing sleeves in such cases allows you to create conditions under which the pipeline in the event of temperature deformations (during installation and operational work, as a result of changing seasons or time of day) can move freely in the walls and ceilings.

- Ensuring the possibility of dismantling a faulty section of pipeline heating without destroying it. However, equipping each building pipeline structure with sleeves is not always advisable, since most often their need is determined by force majeure circumstances.

- Elimination of penetration of odors and insects from adjacent rooms.

The use of waterproof material when sealing the space between the pipe and the sleeve is not always necessary. This is only necessary if the sleeve is in the overlap. For example, if in the event of an accident on a heating riser from a metal-polymer pipeline, water should not penetrate through the interpipe gap to the lower floors.

Determination of sleeve sizes and materials

The inner diameter of a correctly selected sleeve should exceed the outer diameter of the heating pipe by 5-10 mm.

The length of the part must be 20 mm greater than the thickness of the building structure.

In addition, the following should be considered during the liner sizing process:

In a correctly selected sleeve, the inner diameter should exceed the outer diameter by 5-10 mm.

- A protrusion above the ceiling of 50 mm is justified for rooms where there may be cases where the water level rises above the level of the finished floor (in particular, showers). The seal of the product in this case must have waterproofing.

- Excessive protrusion is not always advisable in terms of installation costs - the shorter the structure, the cheaper it is.

- The dimensions of the products should be determined depending on the method of installation of the heating pipeline: with hidden installation, it is possible to neglect the protrusion; for open installation, it is necessary to use parts with dimensions determined by the interior of the room.

In any case, the gap formed between the sleeve and the polymer pipeline fittings should not prevent its high-quality sealing. The inner diameter of the pipe sleeve must allow for the free passage of failed pipeline parts.

General information

Features of installation of internal sewerage

It is necessary to install the pipeline so that when materials of different strengths come into contact, the structures will last for many years.

There are general rules for arranging sewer risers through structural slabs.

Basic requirements for installation work of pipes made of polymer and other materials.

- 1. Pipes of the heating system and water supply, passing through the ceilings, must be equipped with insulation and coating to protect the pipes from solid materials.

- 2. Sewage pipes are covered with rolled material for waterproofing.

- 3. The holes where the riser passes through the ceiling are filled with cement mortar along the entire length of the ceiling.

- 4. The place where the riser extends ten centimeters to the surface of the ceiling to connect to a horizontal pipeline is covered with three centimeters of cement.

- 5. Places where pipes cross the floors, install sleeves ten millimeters larger than the diameter of the pipe. The gaps between the elements are sealed with soft, non-flammable materials. They should not interfere with the axial movement of pipes during linear deformations when temperature changes. The length of the sleeves should be twenty millimeters greater than the thickness of the ceiling.

If metal-plastic pipes pass through the ceiling structures, they are placed in special tubular plastic cases of a suitable size.

Rules for installing oil seals

The process of installing the case is simple and takes little time. It is necessary to prepare in advance a tool for punching the wall and material for sealing the cavities between the sleeve and the wall.

Step-by-step instruction:

- Make a hole in the wall with a diameter exceeding the estimated diameter of the gas pipeline in a location determined by the project.

- Place the sleeve inside the hole and check if it is the right size.

- Fill the gap between the sleeve and the wall tightly with concrete mortar.

- Wait until the solution dries and check the stability of the installation.

The remaining work is usually carried out by gas service employees - they lay the gas pipeline and insulate it.

To pierce a concrete or brick wall, use either a regular hammer drill or diamond drilling - an expensive pleasure, but the result is a smooth and beautiful hole

If the house is wooden, then a large hole in the beam can be made with a drill, drilling around the perimeter or using a large-diameter crown.

The seals are designed for installation in existing communication systems. Accordingly, the product body is made in the form of a detachable structure, upon completion of installation of which the connection to the communication element is fixed using gas welding or electric arc manual welding.

For recommended communications, the gland body is made as a visible one-piece structure only if it is possible to first (and also after installation in the foundation of the building) put the walls onto the communications with further pulling through the communications elements. In case of construction, it is advisable to use the oil seal housing as an embedded part. The oil seal bodies of models C-1 and C-4 are made of sheet metal, and the oil seal bodies of models C-2 and C-3 are made of pipes.

Installation of oil seals excludes autonomous operation of the oil seal device and the building foundation. Together they form a single whole, their subsidence is carried out together, while the installation of compensating devices is carried out outside the perimeter of the foundation, both from the outside and from the inside. The compensating device must be made in accordance with existing regulatory rules.

Padding. The gaps that arise between the pipes being passed through and the bodies of the mounted seals must be tightly filled with hemp strands twisted into a bundle in accordance with the requirements of GOST 9993-74. The thickness of the pre-fabricated bundle must exceed the dimensions of the gap. The hemp strand must be well dried; it should not contain fires, oil, soil or other contaminants.

The strand stuffed into the gap should be compacted layer by layer using strong hammer blows on the caulk or using pneumatic tools. It is possible to impregnate hemp strands with petroleum bitumen of the BN70/30 series, manufactured in accordance with GOST 6617-76 and diluted in gasoline GOST 8505-80. By weight, the composition of the mixture is 5% bitumen and 95% gasoline. After bituminization, the strands must be dried.

Caulking. It is carried out immediately after sealing the gap with a hemp strand, using an asbestos-cement lock that secures the packing. An asbestos-cement mixture is prepared from cement of grade no lower than 400, produced in accordance with GOST 10178-85, and asbestos fiber of grade no lower than fourth, produced in accordance with GOST 12871-93 with the addition of 10% water from the total mass of the mixture.

Before use, asbestos fiber must be dried; the presence of lumps of foreign impurities in it is not allowed. Before adding water, the cement and asbestos fiber should be thoroughly mixed until a homogeneous mass is obtained. Add water immediately before using the solution. The resulting solution must be used within half an hour from the moment of its preparation. Subsequently, the cement begins to set and cannot be used in the future.

Putty. By weight, the putty mastic contains about 70% petroleum bitumen BN70/30, prepared in accordance with GOST 6617-76 and 30% asbestos powder, produced in accordance with GOST 12871-93.

Corrosion protection. Oil seals must be painted with XC-019 enamel, produced in accordance with GOST 21824-76. The thickness of the enamel is 80 microns over a layer of primer GF-021, produced in accordance with GOST 25129-82.

1-stuffing gland S-2 (S-4), 2-stuffing, 3-caulking, 4-putty. Figure 1a - Seal of water supply (sewer) inlet in the ground (basement) floors of buildings in dry soils.

1-pressure seal C-1 (C-3), 2-packing, 3-caulking, 4-putty. Figure 1b - Heating line in the channel. Sealing of inlets in the ground (basement) floors of buildings.

1 – body, 2 – ground bushing, 3 – washer. Figure 2 – General view of the pressure seal C-1.

| 5.905-26.08.1-7.00 | 57 | 7,54 | 8,40 | 9,26 | 10,12 |

| -01 | 76 | 9,00 | 10,04 | 11,08 | 12,12 |

| -02 | 89 | 10,42 | 11,60 | 12,78 | 13,94 |

| -03 | 108 | 12,14 | 13,44 | 14,76 | 16,08 |

| -04 | 159 | 18,96 | 20,80 | 22,66 | 24,52 |

| -05 | 219 | 25,28 | 27,70 | 30,10 | 32,54 |

| -06 | 273 | 31,58 | 34,60 | 37,60 | 34,64 |

| -07 | 325 | 54,44 | 49,04 | 52,50 | 55,96 |

1 - body, 2 - stop, 3 - annular rib, 4 - thrust ring. Figure 3 - General view of the stuffing box S-2.

| 5.905-26.08.1-8.00 | 22-38 | 4,18 | 5,02 | 5,86 | 6,68 |

| -01 | 45, 57 | 4,86 | 5,82 | 6,80 | 7,76 |

| -02 | 76, 89, 108 | 8,34 | 9,88 | 11,40 | 12,94 |

| -03 | 159 | 12,70 | 14,82 | 16,94 | 19,06 |

| -04 | 219 | 22,04 | 25,20 | 28,38 | 31,54 |

| -05 | 273 | 27,38 | 31,06 | 34,74 | 38,40 |

| -06 | 325 | 32,98 | 37,16 | 41,32 | 45,48 |

1 – body, 2 – ground bushing, 3 – washer. Figure 4 – General view of the pressure seal C-3

| 5.905-26.08.1-9.00 | 57 | 8,46 | 9,46 | 10,44 | 11,40 |

| -01 | 76 | 9,82 | 10,90 | 11,98 | 13,08 |

| -02 | 89 | 11,18 | 12,44 | 13,66 | 15,88 |

| -03 | 108 | 13,22 | 14,68 | 16,14 | 17,28 |

| -04 | 159 | 20,44 | 22,56 | 24,70 | 26,82 |

| -05 | 219 | 26,66 | 29,08 | 31,38 | 35,06 |

| -06 | 273 | 32,70 | 35,88 | 39,04 | 42,20 |

| -07 | 325 | 46,92 | 54,40 | 54,28 | 57,94 |

1 - body, 2 - stop, 3 - annular rib, 4 - thrust ring. Figure 5 - General view of the stuffing box C-4.

| 5.905-26.08.1-10.00 | 22-38 | 4,18 | 5,02 | 5,86 | 6,68 |

| -01 | 45, 57 | 4,86 | 5,82 | 6,80 | 7,76 |

| -02 | 76, 89, 108 | 8,34 | 9,88 | 11,40 | 12,94 |

| -03 | 159 | 12,70 | 14,82 | 16,94 | 19,06 |

| -04 | 219 | 22,04 | 25,20 | 28,38 | 31,54 |

| -05 | 273 | 27,38 | 31,06 | 34,74 | 38,40 |

| -06 | 325 | 32,98 | 37,16 | 41,32 | 45,48 |

1 - body, 2 - stop, 3 - annular rib, 4 - thrust ring. Figure 6 - General view of the stuffing box S-5.

1 – body, 2 – ground bushing, 3 – washer. Figure 7 – General view of the pressure seal C-6.

| 5.905-26.08.1-12.00 | 57 | 8,46 | 9,46 | 10,44 | 11,40 |

| -01 | 76 | 9,82 | 10,90 | 11,98 | 13,08 |

| -02 | 89 | 11,18 | 12,44 | 13,66 | 15,88 |

| -03 | 108 | 13,22 | 14,68 | 16,14 | 17,28 |

| -04 | 159 | 20,44 | 22,56 | 24,70 | 26,82 |

| -05 | 219 | 26,66 | 29,08 | 31,38 | 35,06 |

| -06 | 273 | 32,70 | 35,88 | 39,04 | 42,20 |

| -07 | 325 | 46,52 | 54,40 | 54,28 | 57,94 |

Purpose of the protective case

The use of the case is due not only to the protection of the gas pipeline itself from the effects of an aggressive environment and various damages, but also to ensure safety for others.

Everyone knows that a gas leak is a very dangerous phenomenon, so additional protection, in this case, is not a luxury, but a necessary condition. The laying of pipes using a protective casing is strictly regulated in accordance with regulatory documents - SNiP 42-01 and SNiP 32-01. According to the requirements specified in the latest document, not only the pipe laying process itself is regulated, but also the distance at which the ends of the protective casing should be located.

In particular, if we are talking about railway tracks, then the protective case must pass through them and have a length of at least 50 meters from the exit. This great importance is justified by the fact that natural gas is very explosive, and trains have a very high mass. As for highways, the cases must protrude 3.5 meters from the exit. In addition, there are precise instructions on the depth of laying the pipeline, which is about one and a half meters.

Making a case

In accordance with the same regulations, cases must be made of steel pipes. The diameter may be different, because it all depends on the parameters of the diameter of the gas pipeline pipe, but, in general, the diameter will not vary much, the spread will be within 10 cm.