Project of a 4 by 4 meter frame bath, an economical option.

Many people dream of a bathhouse complex or a small steam room. This is a great opportunity to relax, perform wellness treatments and cleanse your soul and body. Baths are traditional for our country and the CIS as a whole, and therefore are not something incredible or unique. Building a frame-type bathhouse on your site is a completely simple process. We propose to describe to you the whole process in step-by-step instructions for building a 4*4 frame bathhouse with your own hands, but you can change its size without outside help.

Floor design in a frame bath

Compliance with all recommendations and instructions for installing the floor will increase the service life of the bathhouse.

A well-made floor will protect against heat loss and rotting of floor boards. In bathhouses where there is direct contact with water, the floor is poured. The most important thing in pouring floors is to ensure rapid flow of water into the sewer.

Step-by-step instructions for installing the floor:

- Laying lags. If the distance between the supports is large – more than 3 m – additional support pillars are needed. Use roofing felt for waterproofing in several layers at the junction of the joists with the foundation and supports.

- For clay soil, a tray is made under the structure to direct water into the drainage pit.

- Installation of boards on joists. The gap for pouring flooring between the boards is about 4 mm. A gap of 2 cm should be left between the flooring and the wall of the bathhouse.

In other rooms of the bathhouse, the floor is non-leakage. To arrange it, 5x5 cm bars are mounted on the logs, and a subfloor is laid on top of them.

Scheme of floor insulation in a frame bath. A waterproofing layer is laid on the subfloor, then mineral insulation is laid on top of which a vapor barrier is laid

After the vapor barrier layer, you can begin installing the finished floor.

Exterior decoration

The timber already has a completely aesthetic appearance.

Therefore, it will be enough to do the following:

- Sand the surface thoroughly.

- Treat with an antiseptic to protect against rotting processes and pest attacks.

- Treat with antipyrine to protect against spontaneous fire.

Exterior view of the wall of a bathhouse made of timber

Preparation for construction: project drawings

Creating a drawing requires certain skills. If they are not there, then it is better to entrust this work to a specialist or use a ready-made drawing.

Before drawing up a diagram, it is important to decide on the following points:

Location of the building on the site

It is important to consider sewer and water drainage. Quite often, the main factor when choosing a location is the laying of communications.

Soil at the construction site

If you plan to make a swimming pool in a bathhouse, then groundwater should not be located near the surface of the territory. The type of foundation to be built will also depend on the type of soil. Bathhouse construction plan and number of floors. If you plan to make a two-story building, it is important to take into account the additional load on the frame structure and foundation. At this stage, you should think in advance about the placement of the stove and what material it will be made of. This will allow you to understand where and which chimney to install, as well as the ventilation passages in the room. Laying communications. It is important to take care of ventilation, electrical wiring, vapor barrier and thermal insulation. It is worth considering the features of water drainage. An important element of any building is the roof. The service life of the structure will depend on it. You should take into account the material of manufacture, as well as its shape. This will allow you to calculate the power of the floors.

You need to include all the information received in the drawing, as well as supplement the project with the necessary details. The more detailed the diagram, the easier it is to build a bathhouse.

The more detailed the project, the easier it is to make a frame bathhouse yourself

It is recommended to draw up a separate plan for communications. If you have little experience, you should not create a complex project. You can use a ready-made diagram, slightly supplementing it based on your own needs.

A standard bath includes a corridor, a dressing room, a washing room and a steam room.

A standard frame bath consists of a dressing room, steam room, shower and rest room

Quite often a separate room for recreation is provided. It is recommended to mark the installation location of the stove on the diagram. If this is a steam room, then it is best to place the stove in the corner closest to the door. The stove can be stone or brick.

It is recommended to determine in advance the dimensions of each room and indicate them in the drawing. The standard dimensions of the steam room are 200x240 cm. The optimal ceiling height is 220 cm. This design can accommodate 2-3 people at the same time.

In the drawing you can see a bathhouse for a suburban area with a balcony measuring 1.5x4 m. The overall dimensions of the building are 4x6 m. The project is suitable for organizing gatherings in an open area in the summer.

A frame bath can be equipped with a terrace for gatherings in the warm season

This bathhouse consists of 3 rooms:

- steam room;

- washing and shower;

- rest room.

The corridor is shown separately in the diagram. There is no room for a locker room. There is a small changing area in the washing room. The terrace connects to the living room.

The optimal wall thickness of a frame structure is 100 mm or more. The wood that is used in the process of making a bath must be treated with an antiseptic. It is recommended to use dried, calibrated lumber.

It is mandatory to perform a vapor barrier of the insulating material on the internal base. In the steam room you need to use foil vapor barrier. The reflective layer can increase the temperature inside the steam room.

Supply and exhaust ventilation is required in all rooms. Floors in the sink should be made with a slight slope or along a screed. The top and bottom floors need to be insulated in the same way as the walls.

The minimum size of a frame bath is 3x4 m.

The minimum size of a bathhouse for a comfortable stay of several people is 3x4 m

The budget version of the frame is made in this way: the racks are sheathed on the inside and outside with boards up to 25 mm, basalt insulation or ecowool is laid inside the frame structure.

If you plan to use ecowool inside the walls, it should be carefully compacted and horizontal platforms for unloading should be installed. The frame must be sheathed inside and outside. To do this you will need to make a sheathing. On the outside, the insulation material is covered with a membrane to protect it from the wind. In the horizontal plane, the use of ecowool is a more economical option compared to basalt insulation.

The outside of the frame structure can be covered with any facing material. The inside of the building is covered with clapboard, plasterboard sheets with tiles or imitation timber.

Layout

Room layout

A DIY sauna made from 4x4 timber has all the necessary elements.

The plan contains:

- Steam room with stove. This is the heart of the building. This is where all the healing sacrament takes place. Dimensions 2.6 by 2 m.

Advice: when installing the stove, be sure to line the space around it with fireproof material to comply with fire safety conditions.

- The sink is the same size. After the hot environment of the steam room, you should rinse with warm or cold water, as you prefer.

- Waiting room. Here you can change clothes, put your things and even sit and relax; its dimensions of 1.4 by 4 m allow you to do this.

Dressing room from inside

- Terrace. An additional element of the building, valid, however, only in the warm season. But it is incredibly pleasant to relax on it on a warm summer evening while drinking hot tea.

Construction of a foundation for a country frame-panel bathhouse

The usual construction of a strip foundation for a building requires 1/3 of the total financial costs for construction and the same amount of time. Due to the fact that our construction will be lightweight, the foundation can be carried out according to a simplified scheme, but a strip or pile structure would lead to an unreasonable increase in the cost of the entire construction. We will make the supporting part of the frame from “bald” car tires filled with crushed stone. After construction is completed, the tires should be protected from sunlight. This will prevent them from breaking. Features of constructing a foundation for a bathhouse in the country:

- After breaking down the perimeter of our bathhouse, the plant layer of fertile soil is cut off from its inside and carefully moved to the garden. As a result of this procedure, you should get a mini-pit 3.5x5 m with a depth of 0.15 m.

- Its bottom is compacted by rolling a heavy steel barrel over it. Then the entire area needs to be covered with fine crushed stone and also “rolled”. As a result, we received a dense crushed stone cushion for the bathhouse in the country, which in the future will evenly distribute the entire load from the structure.

- It is necessary to hammer one peg into the places where the tires will be installed.

- Then the tires are laid throughout the area so that the center of each of them coincides with the peg. The future foundation must be leveled in a horizontal plane. For this, a flat board 4 m long and a building level are used.

- After all the tires are leveled, a pad of any waterproofing material is placed inside each of them to prevent rubble from spilling out when working with the tires. All tires are covered with crushed stone in layers, with each of them compacted.

- Backfilling must be stopped before reaching the edge of the inner rim 5 cm. The crushed stone inside the tire is moistened, and its entire internal cavity is filled with Knauf cement mixture with the addition of filler. Thus, all lying tires should be filled to the very top at the same level.

- After polymerization of the concrete mixture, we obtain a durable layer in the rubber “formwork” that transfers the load to the crushed stone cushion. The rubber of tire beads serves as a compensator for periodic freezing and thawing of the soil.

As a result, when constructing such a foundation, we almost avoid excavation work and have a small consumption of materials: car tires d = 70 cm - 10 pcs., crushed stone - 3 m3, KNAUF mixture - 75 kg, roofing felt - 1 roll. The beam of the lower trim of the frame is installed on supports made of tires.

Types and layouts of baths by type of “nationality”

Roman bath

The Roman bath (therma) consists of several rooms, the first of which is called the “apoderium” and is intended for undressing. Next comes the following - a warm room called a “tepidarium”, then a hot (“calidrium”) and steam room (“laconium”) room, the temperature in which reaches about 85 degrees. This is followed by a cooling and aromatic room called the “lavarium”.

Detailed drawing of the layout of a Roman bath

Irish bath

Irish baths are somewhat similar to Roman ones - they have several rooms with different temperatures - 25, 35 and 50 degrees. While washing, you need to go into each of them and take a good steam.

Russian bath

As a rule, a Russian bathhouse is a wooden building, which consists of two sections: a dressing room and a steam room. In the last compartment, a stove with stones is installed - a heater.

The simplest layout of a small Russian bath

A mandatory element of any Russian bathhouse is a low bench for washing, a high bench for a parka and a broom. The broom is used to warm up and massage individual muscle groups and parts of the body.

Finnish bath (sauna)

The main feature of the Finnish bath is that it has increased dryness and air temperature. This feature is due to the fact that the inhabitants of this cold country prefer to steam in a hot bath with hot air.

In this video you can see the main differences between a Finnish sauna and a Russian bath

Japanese bath

The most popular types of Japanese baths are ofuro and santo. The first of them is a barrel containing hot water (up to 60 degrees) with medicinal herbs and sawdust. The maximum time you can sit in this barrel is 10 minutes. Santo is distinguished by one interesting point - while taking a hot bath, a person must chew on a piece of ice, which improves sweating.

Such a bath can be installed in any small place in your country house

Turkish bath (hammam)

Not as popular as the sauna, but boasts the same ancient history. Belongs to the category of wet baths.

In a hammam, the lower part is heated by supplying hot air from the stove exhaust pipe, which passes under the floor of the heated rooms, located taking into account the longitudinal axis of the stove pipe. In a hammam, the warmest room is located in the center and, as a rule, has an octagonal shape. Adjacent to it are steam rooms - hot rooms, which are equipped with swimming pools.

Modern Turkish baths consist of a large dressing room, a cold shower, a room with a cold plunge pool, an intermediate room and a hot wet steam room. The main distinguishing feature of the hammam is its special temperature regime, which is ideal for people who do not like high temperatures.

Plan and diagram of the arrangement of the Turkish bath hammam

In this video you can see the original types of baths that were presented at the bath festival "BanyaFest"

Flaws

In addition to many advantages, when constructing a frame building there are also some disadvantages:

- The construction of the building itself requires little money compared to other buildings, but it requires considerable cash injections for finishing and insulation (insulation may be inexpensive, but membrane films also cost money;

- The process of closing the insulated frame should be completed within 1.5 - 2 weeks (or even faster, until the insulation gets wet and is not torn by the wind);

- The impossibility of using inexpensive cotton wool and polystyrene foam for insulation (this is a plus about environmental friendliness);

- Finishing with slabs is not recommended in most cases; a ventilated façade is needed.

High cost of finishing

As described earlier, despite the seemingly cheap construction of a bathhouse at first glance, its finishing requires significant costs. Finishing, both external and internal, is the most expensive of the entire process of building a frame bath.

Requirements for the quality of insulation

The disadvantage of the “frame” is the impossibility of using cheap materials as insulation. Only high-quality and therefore more expensive insulation options are suitable.

We also recommend reading the following materials:

- Insulation of the walls of a frame bath;

- Insulation for the walls from the inside and what kind for the steam room;

- Which insulation is better, and also about foil and foil.

Speed Requirements

The construction takes a little time from the developer, but requires proper treatment (the insulation must be closed, otherwise it will get wet - as a result, you will have to buy it a second time, since it can be easier to throw it away than to dry it).

Ventilation requirements

Ventilation is simply necessary for frame construction. Ventilation maintains the necessary microclimate in the building at any time of the year. Unlike hygroscopic wooden walls, frame walls with their vapor barrier create the effect of a “plastic bag” in the bathhouse, similar to a greenhouse or greenhouse. It quickly becomes hot, but at the same time stuffy, you can simply suffocate if there is no ventilation.

We recommend reading about ventilation: in the steam room, diagrams and design, how to do it correctly.

Vapor barrier requirements

The bathhouse requires masterful work with membrane film. If the insulation is carried out with breaks or the joints are poorly sealed, the insulation will get wet and simply stop working.

Shrinkage

The insulated frame must be “closed” within two weeks. The actual shrinkage of raw lumber or “natural moisture” may take a slightly longer period. When the frame boards dry out, construction defects may appear: cracks, film breaks, and cold bridges may appear.

Weakness to wind and snow loads

Despite the fact that the frame is resistant to seismic activity, it is weak against snow and wind loads. The consequence is that the frame should be built in certain areas of the country where these weather conditions are least likely to manifest themselves or allowances should be made for them, which will increase the cost

This disadvantage should definitely be taken into account by everyone who wants to build a frame building.

Fast cooling

Despite the fact that the frame warms up faster, it cools down no slower than its “brothers” (stone, wood), but rather even faster. The reason is the same low heat capacity. The beam, log, stone must first be heated, while the “plastic bag” of the frame does not heat up, but only the air in it heats up. But even when the furnace stops, this air cools down quickly (after all, we will do ventilation, where without it, see above), and massive traditional materials can release the accumulated heat for a long time.

When choosing, you should take this fact into account.

What disadvantages do we take into account during construction?

Like all wooden buildings, a frame bathhouse will have an increased fire hazard. The design should take into account additional treatment with special compounds that will reduce flammability. Insulation materials are selected from the point of view of combustion resistance.

When building frame baths, you cannot skimp on the quality of electrical work. Electrical wiring is placed in non-flammable casings. When installing any electrical appliances, grounding is required.

High humidity in the bathhouse can lead to the destruction of mineral insulation if it is not covered with a vapor barrier. Therefore, it is recommended to use more functional materials as insulation.

All of the above disadvantages lead to higher construction costs.

Selecting a frame bath project

On long winter evenings, we outlined the plan for our future bathhouse.

Photo of the frame bathhouse project we settled on.

Before choosing the material for building the bathhouse, we consulted with the builders for a long time. On their advice, we chose a standard design for a frame bathhouse installed on a pile foundation. This choice is due to the fact that groundwater in our area comes very close to the soil surface, and heaving soil can cause walls to crack if we use brick as a building material. Even if we use a strip foundation reinforced with piles, we still cannot get a 100% guarantee that it will withstand seasonal ground fluctuations.

Creating a Project

Often, owners of land plots, in addition to a residential building and outbuildings, think about building a bathhouse. Of course, you can also buy a ready-made project, created taking into account the customer’s preferences. It is very convenient and fast, but very expensive. It’s not at all difficult to create a project yourself. Moreover, in such a square there is plenty of room for your imagination to run wild. Plus, you can add additional zones to the main zones in the bathhouse (if desired).

You can use standard projects that are freely available on the Internet. Such projects, if necessary, can always be adjusted at your discretion.

Before you start drawing up a project, you should understand how many rooms and what sizes will be in this bathhouse. The following premises must be present there:

- rest room or dressing room;

- sink or shower;

- steam room

It is also important to consider the installation of ventilation and chimney. In order for the bathhouse to be visited by the whole family or with friends, it is worth taking this into account at the planning stage

You can sacrifice the size of the sink and visit it one at a time, but at the expense of this you can increase the steam room and the relaxation section.

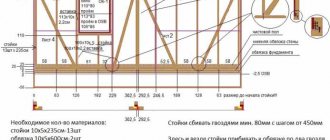

Roof arrangement

The roof of the bathhouse is made of the same boards with a cross-section of 150×50 mm.

In this case, you can assemble the rafter system on the ground and install it ready-made on the top frame. But first, you will need to install and secure a special beam (mauerlat) over the frame, which is used as the load-bearing base of the roof being built. Types of sheathing

After you install the rafter system, you can proceed to arranging the sheathing, made from boards 20 cm thick. Upon completion of laying the sheathing (which is usually carried out starting from the ridge), you can proceed to laying the roofing covering you have chosen.

Peculiarities

When building a compact bathhouse, use standard lumber - planed timber with a length of each product of 6 m. Manufacturers produce wooden products processed on four sides of this particular molding. When erecting walls 3 m wide, the timber will only need to be cut in half, which will speed up the construction process and make the work easier.

Before starting construction work and design, check out the photos of finished baths measuring 3 by 4 to choose the option that suits you. After choosing a building model, the design and construction stages will not be difficult. Due to the compactness of the bathhouse complex, carefully consider the layout of the premises, the location of the heating stove, window openings, and entrance groups.

Straight to the point: don’t confuse technologies!

If you think that a frame-panel bathhouse is the same as a frame bathhouse, just a more detailed and longer name, then carefully read the following sentences. A frame-panel building is built from ready-made panels, which are purchased from companies that professionally deal with them. A frame building can be built by any home craftsman with minimal construction skills and tools. The frame is erected, filled with insulation, sheathed and finishing work carried out. If you need such a frame bath, then go to the appropriate section. If you are still sure that you need information on panel buildings, then read on.

Photo: VIVA HAUS company

External and internal finishing of a summer or winter bath

The frame should not only serve you for a long time, but also be beautiful in appearance.

Experts recommend carrying out exterior finishing work from hardwood boards. Under the finishing it is necessary to put waterproofing material and insulation.

The best finishing material is wood

The interior lining must not only be beautiful, but also withstand high temperatures and humidity. Coniferous wood lining will cope with this task perfectly. Just don't use it in a steam room as it may release resin. Larch lining is more suitable here.

Linden is an excellent option for finishing the ceiling and making shelves and sunbeds.

To decorate a steam room, you need to carefully select wooden lining

Stage III. We lay and insulate floors

In short, to make floors in a frame bath, you need to nail bars with a section of 5x5 cm to the bottom of their logs in the relaxation room, the steam room, and the dressing room, and lay subfloor boards on top of them, then roofing felt, and finally - mineral wool 10 cm thick or expanded polystyrene. And already under the boards of the finished floor you should lay glassine for vapor barrier:

In the washing room, the floor needs to be done differently:

- Step 1. So, in order for it to always be warm in cold times and dry quickly, you need to make a separate foundation along its entire perimeter.

- Step 2. Next, remove a layer of soil by half a meter, and fill the resulting pit with gravel and sand to a 10 cm layer. If water gets into such a drainage well, it will go into the ground, and there will be no need to make a pit.

- Step 3. For the logs of such a floor, it is best to use asbestos-cement pipes with a diameter of 10 cm, which are placed directly on the foundation and filled with concrete so that it keeps them from moving.

- Step 4. Then, in the washing room, a 4-5 cm thick edged round board is laid over the pipes, but with a gap of 6-7 millimeters with rubber gaskets, which are nailed.

- Step 5. After all this, the floor can be pressed down with baseboards.

More details in the video:

Calculation of materials and list of tools

As an example, we will consider the calculation for a frame bath of the most common sizes. The frame is made of timber, the size of the structure is 5x4 m. The base will be reinforced columnar.

For the frame structure, you can use a lightweight foundation made of asbestos-cement pipes

Coniferous wood lining is used to decorate the walls inside and outside. The roof will be gable, the covering will be metal tiles.

A pressing issue is the choice of wood. The material must be dried. Linden, larch or aspen are most suitable. These rocks have low thermal conductivity; they are capable of maintaining their original structure for a long period of time. The walls are erected from boards 2-3 cm thick. Larch or pine slats are suitable for external cladding.

In terms of cost and reliability, a columnar reinforced base is the best option for frame construction.

Columnar reinforced foundation is suitable for the construction of frame baths in most regions

It can be used in most regions. You will need to prepare materials in the following quantities:

- concrete - 2 m3;

- edged boards for the frame - 0.3 m3;

- reinforcing bars - 80 linear meters

The frame can be made from boards, pieces of plywood sheets or OSB. If the soil on the construction site is clayey, then formwork is not necessary.

The most complex and financially expensive part of the bathhouse is the frame. The purchase of materials at this stage must be approached carefully. List of required materials:

- timber 120x120 mm - 5.3 m3;

- mineral wool 10 cm thick - 36 m2;

- vapor barrier material - 40 m2;

- wooden lining - 70 m2;

- material for waterproofing - 40 m2.

To save money, instead of bars you can purchase 50x100 mm boards.

To save money, you can use 50x100 mm edged boards during the frame manufacturing process

The timber must be of the second grade and lower, the board can only be of the first grade. The cladding of the walls on the outside can be done not with wooden lining, but with plastic sheets or corrugated sheets.

The floor is made of edged veneer boards. The ceiling should be covered with clapboard. If you want to save money, you can use mineral wool for thermal insulation. List of materials:

- edged boards - 1.8 m3;

- boards 150x50 mm - 0.2 m3;

- plinth - 20 linear meters;

- mineral wool - 20 m2;

- wooden lining - 20 m2.

You can save money on attic flooring. If you do not plan to use it, then the mineral wool can be covered with unedged boards or pieces of slabs.

The roof is gable, the attic can be used to store tools.

The best option for a frame structure is a gable roof.

There is no need to insulate the roof. The rafters will be hanging. You will need the following materials:

- drainage system - 1 set;

- slats for rafters - 0.2 m3;

- lathing strips - 0.1 m3;

- cornice slats - 0.1 m3;

- metal tiles - 20 m2.

In a bathhouse, quite often, instead of a drain, a blind area around the perimeter is installed using a cement-sand mortar.

List of materials that will also be needed:

- asbestos pipes;

- self-tapping screws;

- nails;

- staples;

- cement;

- gravel or sand.

You will need the following tools:

- square;

- building level;

- roulette;

- electric drill;

- Screwdriver Set;

- hammer;

- pliers.

It is important to think through all architectural and construction tasks, which include:

- internal lining of the bathhouse building;

- selection of optimal materials for construction work;

- actions that are required to ensure the safe use of the structure.

After preparing the tools and materials, you can proceed to construction work.

Features of frame baths

Frame baths are built according to the usual rules for this technique, which makes it possible to do without the use of special equipment or “wet” sand-cement mortars. The important point is the ability to do everything yourself, at a time convenient for you. The main task is the need to understand the principle of creating frame buildings. An important measure will be the interior decoration, which ensures heat conservation and ventilation of the premises.

Design

The basis of the structure is a lightweight frame made of wooden blocks, forming external fences that perform load-bearing functions. It consists of vertical posts installed at intervals of about 60 cm (standard insulation width), reinforced with cross members. Inside and outside, the frame lattice is sheathed with sheet materials (OSB, plywood), and the cavities formed between the slats are filled with insulation. The result is a wall consisting of several layers - the so-called “pie”. In terms of heat conservation, the building is ahead of stone or wooden baths, and its weight is an order of magnitude lower. This makes it possible to do without creating a powerful foundation, eliminate labor-intensive excavation work, and reduce the amount of building materials, which ultimately reduces the cost of the process.

The load-bearing capacity of the frame is large enough to build a two-story bathhouse with several compartments and rest rooms that can accommodate large groups. Floors are also made from wooden parts so as not to create unnecessary load on the walls. The entire frame is assembled from such elements - they are easy to process, adjust and assemble, which speeds up the process and allows you to work alone.

Advantages and disadvantages

Advantages of a frame bath:

- simplicity, high speed of construction;

- work can be carried out on a well-maintained site without causing any damage to existing landscaping elements;

- can be built at any time of the year;

- Finishing and use of the building is permitted immediately after completion of work; there is no need to allow time for shrinkage;

- construction costs are much lower than when using other materials or technologies;

- the ability to do everything yourself;

- no need for complex excavation work or the use of cement mortars;

- the degree of heat conservation of walls and ceilings is much higher than that of brick, log or timber buildings;

- requires less time and fuel to heat up.

However, there are disadvantages:

- the building is very unreliable in terms of fire safety;

- the load-bearing capacity of walls and ceilings is limited, which must be taken into account when creating a project, exterior decoration or subsequent reconstructions;

- wood as a material is not resistant to moisture, which requires increased attention to waterproofing and processing;

- the design of the walls complicates the installation of attachments or furniture;

- External cladding with moisture-proof material is required.

Bath design options

At the beginning of construction work, a design for the future structure is developed. You can do this yourself by using one of the ready-made drawings on the Internet as a template. There is a good alternative that will save time - order a project from specialists. The same team will also handle step-by-step turnkey construction.

There are ready-made modular bathhouses on sale, which are simply assembled according to the principle of a designer and do not require external or internal finishing.

Most popular sizes:

- 3x4 m;

- 3x6 m;

- 5x5 m;

- 6x6 m;

- 6x8 m.

If you decide to make sketches yourself, then you need to consider the following points:

Correct location of the building

It is important to organize a convenient supply of communications here. Type of soil on the site. The type of foundation depends on this

In particular, for a bathhouse with a swimming pool, it is important that groundwater does not wash away the structure. Construction layout, dimensions. If a two-story bathhouse is built, then the load on the frame will be greater. It is important to calculate in advance where to install the stove, determine the height of the chimney pipe, where it will go on the roof. The diagram must indicate where: ventilation, electrical wiring, sewage are located. The shape of the roof, the material for its flooring. The ceiling power is calculated.

For communications, it is advisable to draw up a separate drawing.

On a large estate, a whole bathhouse complex with a terrace, a relaxation room, a dining room, and a bedroom would look good. In such a building it is great to spend time with guests all year round.

Projects with an attic are popular. According to the standard plan, the recreation room on the ground floor occupies up to 20 square meters. m. From it there is a staircase upstairs, where the bedroom is located.

The cost does not differ significantly from a one-story bathhouse

Attention is paid to strengthening the foundation, since the load on it is greater

We recommend that you read:

- Step-by-step construction of a bathhouse with a terrace

- Frame bathhouse with gazebo

In most frame structures for the floor, they use an edged board (rough flooring) and tongue and groove board (finish flooring). All wooden elements are thoroughly treated with antiseptics.

It is convenient to use lining on partitions, walls, and ceilings. For thermal insulation, it is better to take mineral wool and lay 2 layers of vapor barrier on top.

The steam room will perfectly accommodate a wood-burning stove with a water tank. You can lay it out manually from brick or buy a factory made metal one.

Thematic material:

- Brick stove for a bath

- Metal stove for a bath

At dachas, small baths of 3 * 4 m are often installed. It is easier to make them in a square or rectangular shape. Bathhouses in the shape of a barrel, triangular, look unusual. The steam room can accommodate 2-3 people. Inside the building there are only main rooms:

- steam room;

- shower;

- dressing room (dressing room).

A small veranda is allowed. The sauna is heated by a wood-burning stove or boiler.

The main advantages of a mini-bath are the speed of construction and low expenses.

Drain arrangement

The arrangement of drainage from existing water intakes must be taken care of at an early stage of construction of the bathhouse.

Drain arrangement

Firstly, it is necessary to lay a sewer pipe with a slope of 1 meter 3–5 cm. Such a pipe should come from the shower and from the water drain tap from the pipeline system. It is located at the lowest point of the pipeline. Such a tap is needed to drain water from the system and preserve the bathhouse for a long period, for example, throughout the winter. It is better if the drain pipe does not have branches or turns. A straight pipe is a way to avoid blockages. The diagram shows how best to connect two water intakes into one system.

Making a gasket for a sewer pipe

Pipe system

Draining

It is better to connect the sewer pipe to the septic tank so that the drain water does not go into the ground.

Typical characteristics of a 4x4 structure

When drawing up a technical project, you should be guided by the following characteristics:

The area of the bathhouse with an eye to the foundation is about 21.6 square meters. m; The distribution of the area can be as follows: steam room - about 4 square meters. m, dressing room - 3 sq. m, shower room - 3.5 sq. m, terrace - up to 3 sq.

m; As for the ceiling, it is important to maintain a height of 2 m.

Classic sizes are easy to adjust, subtracting useful meters from the same shower in favor of a steam room. Or leave everything to the second floor. However, in this case, you will need to take into account a couple of meters for the flight of stairs.

Calculation of materials

Since we will be building a frame bathhouse measuring 4x4 meters, we will need a certain amount of materials and tools.

Materials

- Cement – Grade 400.

- Sand - sifted coarse.

- Beam - 150x150 mm.

- Beam - 50x150 mm.

- Beam - 40–50 mm.

- Unedged board.

- Boards for formwork.

- Fittings.

- Blockhouse for exterior decoration.

- Thermal insulation material (mats or rolls).

- Foil film for vapor barrier.

- Polyethylene waterproofing film.

- Pipes for sewerage and drainage installations.

- Tap for draining water.

- Ruberoid.

- Antiseptics.

- Metal entrance doors.

- Window metal-plastic blocks.

- Lining for interior decoration.

- Anchors and screws.

- Slate.

- Galvanized chimney pipe.

- Heater stove and water tank for 70 and 120 l.

- Water supply pump.

Tools

Material calculation

Everything must be thought out. You can’t build a bathhouse with everything you can get your hands on – you need special materials. Therefore, it is necessary to keep records of them and draw up an estimate, calculate the approximate cost of construction in order to know how many cubic meters of timber were brought.

The easiest way is to turn to specialists for help, but you can try to do the calculations yourself.

What materials are considered:

- for roof and walls (rafters);

- for the floor;

- ceiling and interior decoration;

- insulation (water and steam);

- for insulation;

- roof.

Depending on the specifics of the bathhouse project, square meters and materials used, an individual estimate is drawn up. A competent and responsible approach to the construction of a bathhouse helps to save your budget and acquire a durable and strong bathhouse.

Stage II. Building the foundation

Building the simplest frame bathhouse with your own hands usually does not require preliminary preparation of the foundation due to its lightness. But, if you don’t want the walls to become damp, then you still have to make a foundation.

Wooden lumber: for a mini-bath

If your bathhouse is at most 3x4, and the walls and roof are planned to be light, then you can put a simple wooden foundation, securing it with stakes on the sides:

This foundation is especially good for capricious clay soils that do not suffer from excess moisture, but are seasonally mobile.

Columnar: for high groundwater

But for construction on uneven and heterogeneous soil, where groundwater is located quite close, a columnar foundation is more suitable:

To build such a foundation, you will not need either equipment or an additional construction team. It is enough to arm yourself with a drill, asbestos or plastic pipes, and know how to mix cement. Then we move on to the following steps:

- Step 1. Level the area.

- Step 2. Mark the location of future pillars.

- Step 3. We drill holes and make waterproofing at the bottom of each of them.

- Step 4. Gradually pour concrete and carefully lift the pipe.

- Step 5. At the 20-30 cm mark, we fix the pipe, waiting for the concrete to harden, and reinforce it.

- Step 6. As soon as the base hardens, fill the pipe with concrete to the end.

- Step 7. We form a grillage - using a regular strong beam.

Economical and simple, which is what you need for a frame bath. And here’s what further construction looks like on such a foundation:

Block foundation: for a light bath

For a bathhouse of medium architecture, where there will be a heavy stove and more than one person walking, a strong foundation made of blocks is well suited:

But building such a foundation is allowed only on soil where the freezing depth does not exceed one meter.

Pile-screw: for difficult soils

You cannot do without this type of foundation if you are building a solid frame bathhouse (or even a bathhouse-house), and the freezing depth of the soil is low. Then you will have to get to a more solid base using modern piles. This is a fairly simple technology, and usually you can get by with a workforce of four people:

- Step 1. Mark the locations of future piles.

- Step 2. We drill holes of the required length, which we calculate based on the data obtained about the soil.

- Step 3. Place the piles and gradually screw them into the ground.

- Step 4. Assemble and secure the harness.

Belt: for reliable soils

If the soil on the site is heaving, then it is better to opt for a simple strip base. In order to build such a foundation, you need to do the following:

- Step 1. A leveling is carried out at the selected location, and a trench is dug along it - about 40 cm wide and 50 cm deep.

- Step 2. The trench must be filled with sand to ground level and compacted layer by layer, constantly watering it with water for better shrinkage.

- Step 3. Place the formwork – 50 cm high and 30 cm wide.

- Step 4. The base of the formwork must be reinforced with metal pipes and rods for strength.

- Step 5. Now you can pour concrete - either in one go, or in layers, but without allowing the previous layer to dry.

- Step 6. You need to put roofing felt on top of everything - to waterproof the frame walls.

Look at the photo of how this is done:

And here’s what the construction of a small frame bathhouse on such a foundation looks like:

You will have to think about a prefabricated strip foundation if you are planning to build a large enough frame bathhouse:

The essence of such a foundation is to create the most reliable support on any type of soil, except for floating ones.

How to build?

After a detailed construction project has been developed and all the necessary materials have been purchased, you can begin building a bathhouse with your own hands. The first stage of construction will be laying out the foundation. If you build a columnar foundation, you will need nine blocks that will form the basis of the structure. Work should be carried out in a certain sequence.

- It is necessary to prepare a plot of land for construction, preferably on a flat surface. This area is cleared, debris, grass, and shrubs are removed.

- Make markings for the foundation and install formwork.

- Pour the foundation and install pillars in the prepared places, which will serve as the foundation of the entire structure.

- Next, you need to leave the base for several days until it dries completely.

After this, you can proceed to the construction of the building frame. It is most often made from wooden beams. It is necessary to treat the material with an antiseptic in advance so that it lasts much longer. Marking is carried out, the material must be laid along the outside of the building and secured with nails.

After finishing the piping, you can move on to arranging the walls. They are also made from wood that has been prepared in advance and treated with an antiseptic solution. The boards are attached very tightly to each other on the axis

It is important not to forget about door and window openings. Professionals recommend equipping a stand at the point where the frame is connected to the wall for greater structural strength.

The construction of walls should always start at the corners to prevent the structure from slanting.

Having completed the construction of the walls, you can proceed to arranging the roof of the bathhouse. All work is carried out according to a standard scheme. It is necessary to provide excellent ventilation to ensure that steam and condensation do not accumulate under the roof. Doors and windows can be installed in the formed door and window openings. You may prefer a metal one as an entrance door, while wooden ones are suitable for internal ones.

It is necessary to take into account that the door to the steam room must be made of thick wooden beams or tempered glass in order to maintain the temperature in the room well.

After erecting the foundation, walls and roof of the building, it is necessary to carry out the external finishing of the frame bathhouse. Here the choice of materials is unlimited and depends only on the imagination and material resources of the owner. The following materials are well suited for exterior finishing:

- tile;

- plaster;

- siding;

- boards;

- eurolining.

Lining is certainly suitable for finishing the inside of a bathhouse. It is a natural material, environmentally friendly, and does not pose any harm to humans during severe temperature changes. In addition, it is very durable. It is worth abandoning the interior decoration using such popular plastic panels today. When heated too much, they produce harmful chemicals and can even melt.

It is also better to make the floor from wooden planks. But you should not cover them with paints or varnishes that cannot withstand high temperatures. It needs to be well polished and simply treated with an antiseptic.

Floor

We insulated the floors in the bathhouse. The steam room and shower have tiled flooring, and the dressing room has laminate flooring. First, I’ll tell you about the steam room and shower; there are many more important nuances there.

Laying tiles

The tiles were purchased with a matte finish and rough so that they would not slip. We decided that tiles are much better than wooden floors - they don’t rot and are easy to clean. The glue was purchased with the best moisture resistance characteristics.

Waterproofing was laid on the subfloor, overlapping the walls. On top of the waterproofing, insulation was laid - EPPS (thickness 30 mm). For better adhesion of EPS to the waterproofing, assembly adhesive was used.

A screed was poured over the insulation along the beacons with a slope towards the drain funnel. Before pouring the solution, a reinforcing mesh and a set of beacons were laid. The photo shows that we attached the beacons not to the floor, but to an asbestos solution - we laid out piles and pressed profiles into them. The solution (cement with sand) was mixed in a rented concrete mixer, because

It was important to fill the entire floor in one day. The solution was laid out from the bucket with a trowel onto the grid between the beacons and leveled with a wooden plank - the rule

The floor was finally leveled with a wide trowel and grout.

The tiles were laid away from the drain gutter to make it easier to maintain the slope. Each one was pre-soaked in water. The glue was applied with a notched trowel onto the dried and primed screed. In this case, glue was not applied to the entire surface of the floor at once, but only to the space for laying 1-2 tiles. The glue hardens quickly and should not be used to cover a large area of the floor at once. The thickness of the adhesive layer was kept approximately equal to the thickness of the tile. I collected the excess glue around the laid elements with a simple narrow spatula.

First, all rows of whole tiles were laid out, then parts along the walls. We cut the tiles with a manual tile cutter. By the way, for precision masonry we pulled the fishing line and used crosses for the seams. And for better contact of the tile surface with the binder, immediately after laying, I lightly tapped each square of tile with a rubber mallet.

Laminate

The laminate flooring was installed very quickly. We covered the floor with film over the insulation, nailed down moisture-resistant plywood, and rolled out the backing.

I unpacked the package with a knife. He took out the first panel and laid it down, turning it with a small protrusion towards the wall. I inserted 2 plastic wedges between the wall and the board. I took the second strip and snapped it into the end groove of the first. I leveled it and placed the wedges again. When I reached the opposite wall, I used a circular saw to cut off the extra piece of the laminate panel. The next row began from the segment. The second row was assembled in the same way as the first, after which I lifted the entire floorboard at an angle of 45 degrees and carefully connected it to the latch of the first row, and then hammered it through the block with a mallet. The last row had to be sawed lengthwise, precisely measuring the cutting line.

Finishing

Finishing the premises inside and outside the walls can begin after covering the roof frame with a roof and installing subfloors.

Internal

The inside of the bathhouses should be decorated with clapboard. The most important thing is not to stuff it too tightly. The tree needs distance to dry out freely.

The lining must first be coated with special antiseptics, which will protect the wood from the destructive effects of moisture.

External

For exterior decoration you can use different materials:

- block house;

- metal or plastic siding;

- different types of plaster;

- clinker tiles;

- decorative brick.

The choice of decorative material depends on the wishes of the bathhouse owner and his financial capabilities.

Frame buildings are present in every modern cottage cooperative. This is due to the increasing popularity of this technology. To build a high-quality frame bathhouse, you need to understand how to build it correctly and prepare the necessary set of materials and tools.

Stage I. Design

So, using frame technology, you can build either a small steam room with a steam room and a dressing room, or a two-story country house-sauna.

It all depends on your imagination and financial capabilities! For a small frame bath you will need to make a simple strip or columnar foundation, purchase dry timber with a cross-section of at least 20x20 for the racks and an edged board:

For a frame bathhouse with at least three rooms, a simple timber foundation is no longer enough:

If you wish, in order to save building materials, you can make a dressing room separately, like an attached veranda, then there will be enough space inside for a steam room and a washing room:

But abroad, frame construction of entire two-story houses is quite popular. Naturally, a reliable foundation is needed here (more on this below), and good material:

Or make your bathhouse more spacious in area, instead of the second floor:

Why is this option better? The fact is that frame baths are the most fire-unsafe. And the worst option is if at the time of the fire you and your friends are in the billiard room on the second floor. The fire rises quickly, and you simply have to jump into a snowdrift - this time not for reasons of health and extremism after heated procedures. But if it happens in the summer...

Differences and features of technologies

Frame

- The supporting structure is a wooden frame on which all building elements are attached. The bathhouse is installed on the site without the use of equipment. This is 100% handmade. It is possible without the involvement of specialists.

- When designing a frame bath, any customer requests are taken into account. The only restrictions are regulations.

- Quick commissioning of the facility.

- Frame baths, including mobile ones, have the most affordable price. The cost can increase: a) increasing the size of the bath; b) type of foundation; c) expensive materials for interior and exterior decoration; d) type of insulation; there are recommendations for insulating the roof, walls, floor and ceiling of the bathhouse; e) independent work or with the involvement of specialists; f) engineering additions...

- They are strong and reliable. A large number of stiffening ribs prevent the structure from deforming.

Frame-panel

1) The production of frame-panel baths is a complex, expensive process. The main structural element is SIP.

The design of SIP (structural insulated panel) is similar to a sandwich. Between two sheets of wood-based material there is a thermal insulation layer.

There is a wide variety of SIPs on the market. But, since you are interested in a bathhouse, then look for a sandwich where the outside is oriented strand boards with the abbreviation OSB, and the inside is polystyrene foam.

The middle layer binds the entire structure together using a special high-pressure adhesive (cold pressing). The wood leaves are strictly parallel. Waterproof treatment of slabs is carried out during their manufacture.

Individual design is not possible. Always a ready-made standard design solution.

2) This bathhouse is assembled quickly (2-3 days). All blocks and elements are clearly adjusted to each other in the factory.3) The cost of frame-panel technology increases due to:

- expensive production;

- attraction of lifting equipment;

- possible increase in the number of construction crews.

4) The panels are attached to each other using a wooden beam, the selection of which requires special attention, according to the “tongue and groove” principle.

The joints are sealed with polyurethane foam. Vertical and horizontal bars provide additional rigidity and stability.

5) Panels can last more than 50 years.

Advantages and disadvantages

To appreciate this technology, let’s watch a video from a well-known channel, and then look at its pros and cons.

pros

- Fire resistance: the panel is capable of holding back fire for an hour, the ANTI-FIRE treatment is effective.

- The panel material is non-toxic and safe for humans.

- The panels can withstand heavy loads: everything can be mounted on them, even heavy hanging furniture.

- SIP walls are thin, but retain heat well.

- Smooth walls inside and out: any finishing materials.

- Resistant to temperature changes. Build baths all year round!

- SIPs are excellent sound absorbers.

- Thermal losses of sandwich structures are minimal.

- Moisture resistance: SIPs do not rot, mold does not form on them.

- Seismic resistance: buildings can withstand vibrations of more than 5 points.

For your information! A frame-panel bathhouse is more expensive than a frame one, but half the price of a log house.

Choose frame-panel baths to suit any budget:

Turnkey (cladding of facades and internal walls is carried out at the sandwich panel manufacturing plant); Rough finishing (decoration either inside or outside - at the customer’s choice); Without finishing (the customer carries out internal and external finishing on his own).

Photo of the company ProSIP (St. Petersburg)

Minuses

The service life is limited to 50 years. When heated above 125 degrees, the thermal insulation layer burns and deforms. External uniformity and unattractiveness of objects without finishing. Violation of technology leads to loss of strength.

VERY IMPORTANT! Lay the electrical wiring correctly, paying special attention to the areas where sockets and switches are attached. A spark may cause the inner layer of the sandwich to ignite. For the same reasons, use non-combustible materials for finishing.

ATTENTION: seal all cracks and gaps, otherwise all the thermal insulation will be damaged by rodents.

Tips for finishing and insulation

The outside of the bathhouse is covered with siding, boards, plaster or ceramic tiles. Waterproofing material should be laid under the sheathing. The resulting gaps can be filled with thermal insulation material. You need to leave a small gap between the clapboard and the foil for ventilation. For this purpose, strips several cm thick should be nailed to the vertical supporting parts. The distance between the elements must be selected taking into account the distance between the supports.

In the diagram you can see the design of the wall cladding

To give rigidity to the walls, they need to be covered with plaster shingles. After the cladding work is completed, the outside of the structure must be plastered.

Guidelines for internal cladding of frame buildings:

- The inside of the building should not be painted, as paints and varnishes will release harmful chemicals when heated.

- To make a rough ceiling, you should use OSB boards. They must be secured to the bottom of the floor beams.

- The walls in the steam room should be covered with foil. The remaining walls can be covered with glassine.

- The minimum ceiling height is 2.2 m. In this case, it will be possible to install lining and additionally insulate the ceiling.

- It is important to pay attention to the joints between the walls and the ceiling structure. The vapor barrier material must protrude at least 15 cm.

The slats can be nailed in using different methods - during the fitting process, a selection is made into a groove or a quarter. The slats must be attached to the joists with the front part.

There is no need to make holes between the foil and the corrugated sheet; the sheets are nailed to the foil. Fixation is done using self-tapping screws with rubber gaskets.

After this, the furnace and boiler are installed. It is important to remember fire safety rules. The wall that will be used for the soaring room and resting place must be made of brick. It is recommended to place the heating boiler in the dressing room. The best option is a brick stove, but if you have no experience in laying a similar structure, it is recommended to entrust this work to a qualified stove-maker.

When working with foil, you need to be careful, as the material is easily damaged. Any gaps will significantly reduce the effectiveness of thermal insulation. The vapor barrier should be fixed with a stapler, and it is important to ensure that there is no sagging of the material. The minimum distance between the wooden paneling and the insulating material is 1 cm.

In the bathhouse, it is best to attach the foil using an ordinary stapler

Frame structures are convenient in terms of finishing. Work can be done both inside and outside. If there is a forced break, you can make partition frames at this time, upholstering them with blockhouse or clapboard. In this case, the time will be spent usefully.

For most regions, the optimal thickness of the walls of a frame building is 10 cm. Insulation can be done either with mineral wool or with expanded polystyrene. A layer of mineral wool 12 cm thick can replace a wall made of bars 50 cm thick.

You can insulate a bathhouse from the inside using mineral wool

For northern regions with cold climates, there are 2 methods of insulating a bath:

- Making a frame from slats 15 cm thick. The insulating material must be of identical thickness.

- Sheathing the walls on the outside with OSB sheets or plywood, followed by installation of expanded polystyrene boards 5–10 cm thick.

For the northern regions, it is recommended to cover the outside frame with OSB boards

If you plan to use expanded polystyrene, then after installing the sheets you need to make a thin screed using a mesh of reinforcement. Finally, a topcoat should be applied.

It is not recommended to use traditional insulation materials made from sawdust and straw.

It is not recommended to use sawdust and clay to insulate the ceiling

During the cooking process, they will be mixed in water with clay, and therefore the insulation will have a lot of weight. In addition, a large amount of liquid often causes wet ceiling parts made of wood. This has a negative impact on the performance characteristics of the bathhouse building.

Frame walls are an excellent bait for rodents who love polystyrene foam. In 2–3 years, solid sheets can turn into dust. Therefore, it is not recommended to use polystyrene foam for insulating rooms inside a frame structure.

Particular attention should be paid to the quality of vapor and waterproofing. Such a bathhouse does not have free supports; each of them will carry the load and hold other parts of the building. If the strength is compromised due to prolonged exposure to moisture with one rack, the sauna may become unstable. In this case, complex repair work will be necessary. It is best to prevent such a situation at the stage of insulating the rooms.

To insulate the insulation, it is best to use aluminum film.

It is best to insulate the insulation with aluminum film

However, the material is not cheap. If you want to save money, you can use plastic film. The material is cheaper, but in terms of steam and water protection parameters it is practically not inferior to foil. It should be remembered that polyethylene can be damaged when exposed to sunlight. For this reason, it is important to cover the frames. This will reliably protect the film from exposure to ultraviolet radiation.

Important features when constructing a frame bath

A frame bath requires high-quality thermal insulation. Mineral wool or basalt is suitable as a thermal insulation material; fiberglass insulation is also suitable.

An important point is vapor barrier. In rainy weather, and in winter during snow, moisture enters the bathhouse through cracks, forming condensation inside the frame, as well as on the walls and ceiling. To cope with this problem, hydro- and vapor barriers are used.

Wood for a bath should be selected well dried, because when the wood dries out, it decreases in volume and cracks appear. The best option for a bathhouse is larch, aspen or linden.

Internal and external decoration of the bath

For the exterior finishing of frame baths, imitation timber or siding panels are used. Interior decoration requires special attention. First you should choose a lining. For the rest room and vestibule, you can choose pine. It requires no maintenance and looks quite impressive.

The steam room is decorated with linden or larch. These breeds are not afraid of high temperatures and are able to retain color. Sometimes other wood is chosen:

- Abashi is a tree from tropical forests that has low thermal conductivity;

- cedar – when heated, it begins to release essential compounds that are beneficial to the body;

- Aspen – this tree is resistant to rot and mold.

Important! The lining is attached to the vapor barrier in such a way that there is a gap between the wood and the foil material